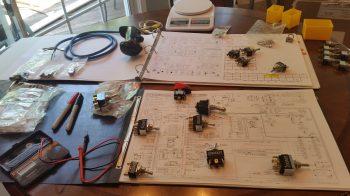

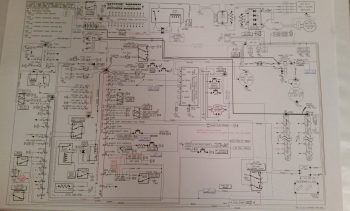

Over the past few days I’ve pretty much finalized all I can with my electrical system planning at this time. I would hazard a guess that over the past couple of months I’ve moved the “finish” dial on my electrical system design & documentation from the 89-93% range to the 96-97% complete range. There are still a few more admin things I need to finish, and depending on any future changes in vendor-mandated installation requirements on my respective components, I’ve pretty much got the design dialed in to the point where I can implement the electrical system plan where permitted from here on out as I build. I do have a couple of switchology decisions to make, but those won’t come until I mock up the panel and play around in a simulator-type setting while making airplane noises.

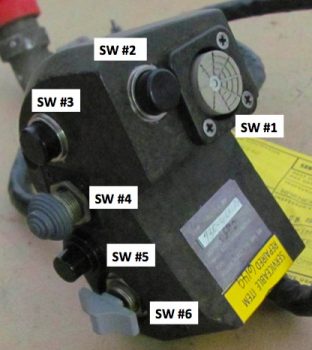

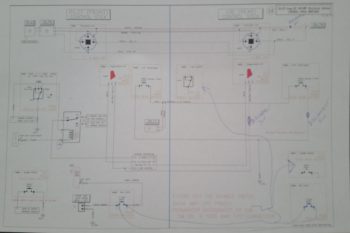

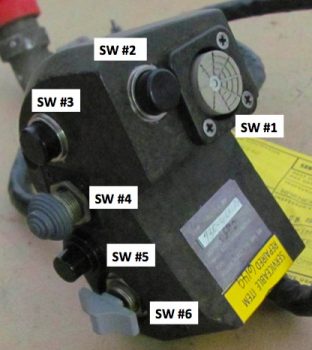

Moreover, I met another design milestone by creating wiring diagram 13 showing all the wiring for the 6 throttle handle-mounted switches. Since I’m making the throttle handle removable I’ll be running all the wires through a 24-pin AMP CPC connector–the same style connector that I used on the nose gear actuator connectors where I swapped out the stock Molex connectors. On the throttle handle I’ll be wiring all the switches with new wiring and swapping out the old stock circular Amphenol Mil-Spec connector with the much lighter and cheaper TE Connectivity AMP CPC connectors.

After removing all the existing electrical potting material and then stripping all the throttle handle switches of the myriad of resistors and capacitors, which created a near-impenetrable labyrinth around the back side of each switch, I was able to tone all the switches out. I was pleasantly surprised to find that I had mistakenly ID’d the bottom toggle switch as a SPST switch rather than the DPDT switch that it actually is. I had already targeted an $80 OTTO replacement switch for this position, but after this latest round of investigation I can belay that order and use the stock switch for my Landing Brake!

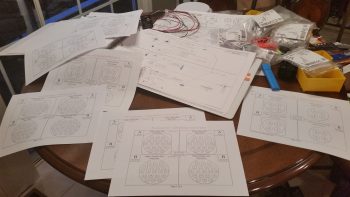

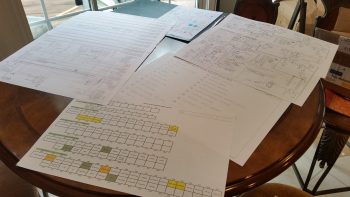

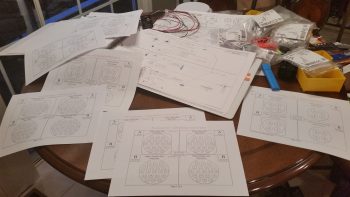

With my throttle switches clearly identified, and the wiring to & from each switch, I could then marry up my initial throttle switch diagram with the 24-pin AMP CPC connector and finalize the throttle handle’s P4 connector pinout diagram. I have all my multi-pin circular connectors detailed in a PowerPoint slide deck (it just evolved that way). And since I currently have seven connectors on the aircraft (P1-P7), I obviously need a diagram for each connector. Unfortunately, I hadn’t created all the diagrams, so down another rabbit hole I went for a couple of hours to finish all the templates for all the circular connector pinout diagrams, as you can see in the pic below.

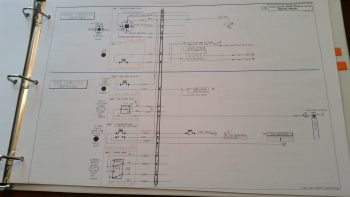

Now, each connector pair gets 2 pages detailing the pin assignments. The first page (top of the 3 pages in the pic below) details the general information about each connector: number of pins, part numbers, mounting flange (if present), hole number schema, pins, sockets, and standard vs reverse sex connector. The second/back page (middle & bottom in pic below, with bottom page info populated) shows the detailed pinout for each connector side, with wire colors and wire function/connectivity. I of course finalized populating all this information for each side of the P4 throttle handle switches connector.

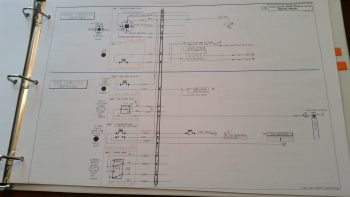

As for wiring diagram 13 depicting the wiring for all the 6 throttle handle-mounted switches, below top you can see the initial draft versus draft #3 in the second pic below.

I knew that the top left throttle handle switch that was clearly designed for a specific F-15 system was not going to work for my application. This switch is nearly heavier than all the other switches combined and in my estimation is probably a good 30% of the stock weight of the throttle handle as it was shipped to me. I pulled this switch and then spent a fair amount of time identifying its replacement.

And here’s what I came up with: the OTTO T5 mini trim switch. The more complete description is a commercial grade 4-way plus center pushbutton trim switch. The pic below is a stock photo off the Mouser website. In actuality, the switch I ordered does have the “stadium” grips on the top as this pic shows, but it differs in that my switch is gray and it is press fit vs. threaded mounting. If you’re curious about the switch assignments, here they are:

- UP – Trio Autopilot Fuel Information Screen Cycle

- DOWN – AFP30 Air Fuel Data Computer Screen Cycle

- LEFT – GRT HXr EFIS Page Flip

- RIGHT – Garmin GTN650 NAV Source Select

- CENTER – Garmin GTN650 CDI Source Select

As for the other Throttle Handle Switches, here’s the layout:

#1 – Outboard Front – 5-Position Mini Switch (described above)

#2 – Inboard Front – COM PTT

#3 – Inboard Side Top – COM1 Freq Flip-Flop

#4 – Inboard Side 2nd Down – Nose Gear UP/DN

#5 – Inboard Side 3rd Down – A. Remote Start Arm B. Trig TT22 XPDR Ident

#6 – Inboard Side Bottom – Landing Brake UP/DN

Alright, moving on!

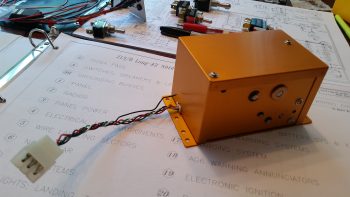

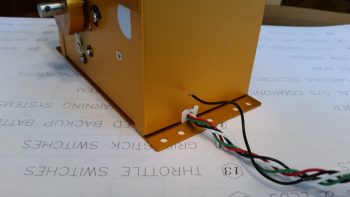

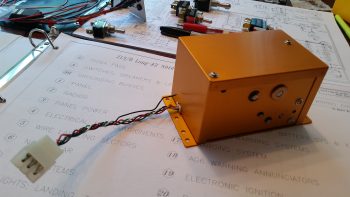

As I was reviewing the P-connectors pinout diagrams, I set about to confirm some info on my P3 (Trio autopilot pitch servo) & P7 (Trio autopilot roll servo) connectors. For some reason our good friends building non-TSO’d products for our birds typically use auto grade Molex connectors. Being a true disciple of Bob Nuckolls, and having had other discussions with some smart bubbas on this topic, I am simply (and clearly) not a fan of Molex connectors. Especially for the autopilot roll servo which will be located on the back of the center section spar in the engine compartment. I want more environmental protection for this connector. So, my dear friends, I was confirming the wire colors and pinouts on the P7 connector with the Trio install manual–since I had just ordered a reverse sex 4-pin sealed connector (so that it was physically impossible to connect up either servo in the wrong spot) on my last Mouser order– AND that’s when a disturbing question popped up concerning both the P3 connector, and the pitch servo.

You see, I had incorrectly ordered a 4-pin connector for the pitch servo in my haste to get all the required electrical pieces parts in hand. It didn’t require any O-ring seals since it was in the avionics bay, so I simply pulled the trigger. But while reviewing the Trio autopilot installation manual wiring diagram, I realized I had forgotten about the 2 extra wires coming from the pitch servo for the Auto Trim feature. But why had I forgotten these wires? I then pulled the pitch servo out and –what?!– only 4 wires! Hmmm, maybe they were tucked inside the servo since this was an “optional” (key word here folks) feature. I pulled the cover off the servo, and no joy. There was not an extra pair of wires or connection points inside this servo. Ok, what’s going on here?

I went to Trio’s website, and I still got the impression that the Auto Trim feature was a standard feature of Trio’s Gold Standard servos and merely labeled as “optional” since the builder had to add a relay, bridge rectifier and wire it all up for it to work.

I called Chuck at Trio to ask him about this latest puzzling revelation. He and the Trio gang were just getting ready to head out the door to Oshkosh, but he took the time to have a detailed conversation on the status of my pitch servo. So here’s the deal: A few years ago the Auto Trim feature was an actual priced option for the Trio Gold Standard servo. However, they decided to simplify production and simply make the Auto Trim a standard feature on the pitch servo, yet still optional as to if the builder/owner wanted to utilize it or not. Since this was my impression all along, it never entered my brain as a data point when I bought these servos from a fellow homebuilder (Rans S7 I believe) off of Ebay. If you recall, I had the servos sent straight to Trio who made one engineering upgrade, ops checked the servos and then sent them on to me with the install kit required for a Long-EZ. All was good! Or, so I thought. Hmmm…

Okay, lesson learned! The money I saved on buying these servos off of Ebay has been reduced to virtually nil now that I’ll be sending the pitch servo back to Chuck, along with a couple hundred bucks, to have the Auto Trim feature installed. All in all, no big deal. I’m just glad I caught it early on. And I guess technically this was two Oops since I also had to spend $10 to include all the pieces to make up a 7-pin AMP CPC connector on my last Mouser order! [Note: I’m using a 7-pin connector since they don’t make a 6-pin.]

In closing, I currently have everything either on hand or on order for my electrical system. As I did a couple of years ago, I’ve included a rundown below of all my electrical system diagrams (wire book) up to this point. As you can see, I have a few more systems to figure out, but nearly all of the really critical stuff is complete. As for the Main, Battery and E- Busses, I won’t diagram those out until all my other system designs are completed and installed.

0. Index Page

Z. Z-13/8 Electrical System

A. Switches, Circuit Breakers & LEDs

.99 Grounding Busses

1. Panel Components

2. Radio & audio system

3. Panel Power

4. Electrical System Components Location Diagram

5. Aircraft Wire Labeling Sectors Diagram

6. Nose Gear

7. Pitch & Roll Trim Systems

8. Lights: LDG, TAXI, NAV, STROBE

9. Engine Info Management

10. Fuel System

11. Cockpit Lighting

12. Landing Brake

13. Throttle Handle Switches

14. Control Stick Switches

15. Integrated Backup Battery System & X-Bus

16. Alarm & Warning Systems

17. Charging System

18. AG6 Warning Annunciators

19. Electronic Ignition

20. P-Mag Ignition

21. Heater System

22. Starting System

23. ELT

24. Heated Pitot Tube

25. Trio Autopilot

27. Main Bus

28. Battery Bus

29. E-Bus

30. Long Wire Runs

This wraps it up currently for my electrical system design and planning. From here I’m going into house cleaning mode (multiple out of town visitors arrived and/or arriving!) and shop cleaning & organization to move forward on the actual build… woo-hoo!