Last night I had finished making both a long list of notes –including questions to ask different vendors– regarding my in-cockpit XM weather capability using my WxWorx receiver. Overnight I had an epiphany on two fronts. The first was that I resigned myself that I was only going to pipe XM satellite weather into my cockpit on one device: my Bendix/King AV8OR portable GPS.

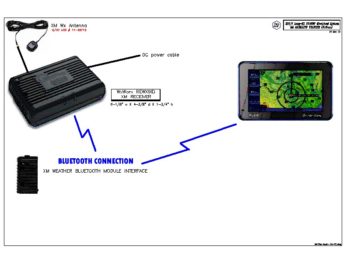

The second was that instead of messing about with trying to figure out how to purchase a nearly-impossible to find (original optional component) RS232 cable for a hard-wire setup between my XM Wx receiver and display (AV8OR), that I would instead look seriously at using Bluetooth betwixt the two.

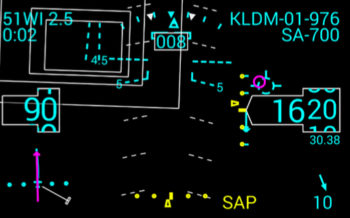

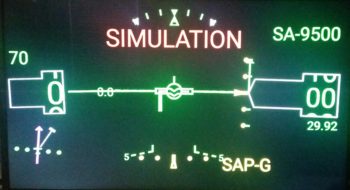

You may be wondering why I’m not pushing to have my HXr EFIS display XM Wx data, and at first I was very much intent on doing just that. However, having dug into the XM Wx display capabilities of GRT’s HXr EFIS, it honestly just doesn’t match up nearly as well in displaying various XM weather products as the AV8OR does. Yes, although a bit older platform, the AV8OR simply beats out the HXr in XM Wx display at just about every turn (except display size).

The bottom line is that in my realization of the amazing & difficult number of technical/logistical hoops I’d have to jump through to get the XM Wx to display on both the HXr (fewer XM Wx products) and the AV8OR GPS (nearly all XM Wx products), I was driven to an undesired —but EZ— decision to go with just the AV8OR to display my in-cockpit XM Wx data. To be clear, I will still display NexRad Wx data on my HXr EFIS, but just via ADS-B.

To provide somewhat of a full scope report, I will say that I discovered a device —Mobile Link— now offered by Baron (AKA “WxWorx”) that translates the XM Wx data across a WiFi signal to be used on up to 4 portable devices such as iPads, iPhones, and Android phones/tablets. Upon a closer look however, I unfortunately discovered that Mobile Link provides an either-or solution, not an either-and solution in that I could either go the Mobile Link route for JUST a WiFi solution (mobile), or with my current XM Wx receiver to panel device solution (EFIS, GPS unit, etc)…. but not both. Since it would cost much extra for Mobile Link, I decided not to go this route and will continue looking for more viable solutions to get XM Wx on my mobile devices…. specifically on my iPad for Foreflight.

In narrowing my target focus, I again decided to shoot for getting my XM Wx data solution implemented with the most elegant solution possible. Although I currently have a USB cable connection on my XM Wx receiver, I still had a nagging question on just how exactly that would interface with my AV8OR GPS unit. What I did know however, is that it would require an optional cable which I do not currently have on hand. Note, that “cable” here is also a significant, operative word. The bottom line is the location and fit of my AV8OR on my panel is very tight, and introducing a new cable would add to its complexity of getting it situated on a tightly packed panel and its use (removing during non-use and during fly-ins, etc).

Although an unexpected expense, by purchasing the XM Wx receiver Bluetooth module from Aircraft Spruce, it knocks out the proverbial 2 birds with 1 stone: 1) It solves all questions about connecting device A (AV8OR) to device B (XM Wx receiver, and 2) it makes the install overwhelmingly much cleaner and easier. So, I pulled the trigger on the Bluetooth module.

Fellow builders that know me know that I often use a term, half in jest, that it’s “better to be lucky than good.” And as I’ve shared with you before, an old boss of mine used to so wisely say, “Luck is when preparation meets opportunity.” Well, I think both of those came into play today since I was able buy literally the last Bluetooth module that Aircraft Spruce had in stock for a 2nd generation XM Wx receiver.

On top of that, since the Bluetooth module replaces the USB cord module it then goes to reason that another power source is required (since the USB cord provided it in the wired configuration). Well, due to a note on the Aircraft item page for the Bluetooth module that some of these peripheral items may be available, after a short hold while the very helpful Aircraft Spruce sales rep called the company that makes the power cords, I was happy to hear that I would be allowed to purchase one of just a few power cords they had left… Woo-hoo!

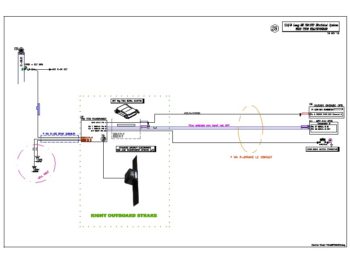

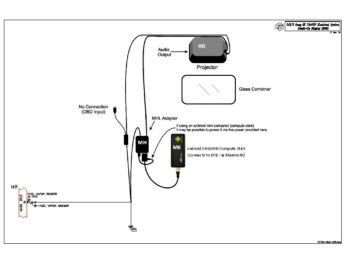

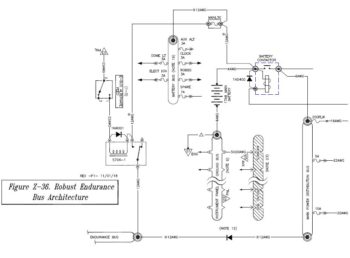

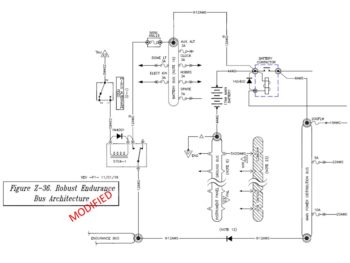

With my initial XM Wx data solution seemingly resolved, I then pressed on to creating a wiring diagram for the Trig TT22 Mode-S transponder. I have depictions of its install in a few other diagrams, but since I decided to place it in the outboard pocket of the right strake, I figured I had better expound a bit on the particulars of its wiring and installation. Thus, here is the resulting transponder wiring and installation diagram.

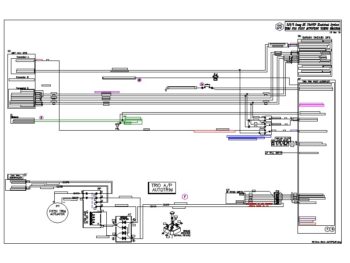

The transponder wiring diagram above is actually a significant milestone in my build, since it caps a near 5-year effort to document my entire electrical system and components into individual diagrams. So, for those of you that are interested, here’s the latest updated list showing all my Electrical System Wiring Diagrams:

0. Index Page

Z. Z-13/8 Electrical System

A. Switches, Circuit Breakers & LEDs

.99 Grounding Busses

1. Panel Components

2. Radio & audio system

3. Panel Power

4. Electrical System Components Location Diagram

5. Aircraft Wire Labeling Sectors Diagram

6. Nose Gear/AEX System

7. Pitch & Roll Trim Systems

8. Lights: LDG, TAXI, NAV, STROBE

9. Engine Info Management

10. Fuel System

11. Cockpit Lighting

12. Landing Brake

13. Throttle Handle Switches

14. Control Stick Switches

15. Integrated Backup Battery System & X-Bus

16. Gear & Canopy Warning

17. Charging System

18. AG6 Warning Annunciators

19. Electronic Ignition

20. P-Mag Ignition

21. Oil Heater System & Seat Warmers

22. Starting System

23. ELT

24. Heated Pitot Tube

25. Trio Autopilot

26. Video Camera System

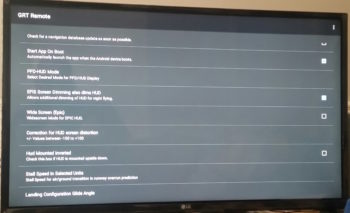

27. Heads-Up Display (HUD)

28. Transponder

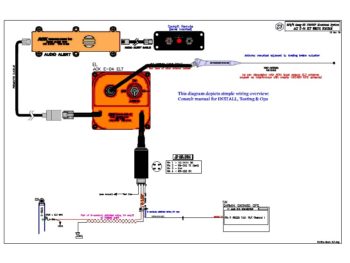

29. XM Weather

30. Long Wire Runs