I started today by taping up the side rails so that only the area that will lie under the ends of the cross bar was exposed.

I then shot each side rail with weldable primer.

I then removed the tape after I had pulled out my chop saw from the back shed & prepped one of the 7/16″ stainless steel bars (that will be used for the aileron weight) to cut 2 pieces 7/8″ long.

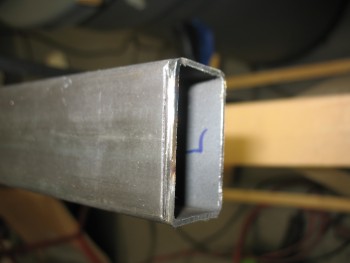

Here are the two 7/8″ long pieces of the 7/16″ diameter stainless steel cut to be inserted into the crossbar as support inserts for the seat belt mounts. I’ll drill 1/4″ holes through the center of these inserts & weld them into place in the crossbar.

Here are the side rails re-inserted after the weldable primer had cured.

With the side rails completed, it was time to fit the crossbar into place. I marked the cross bar & trimmed each side a very little at a time.

Here I’m trimming the left side of the cross bar.

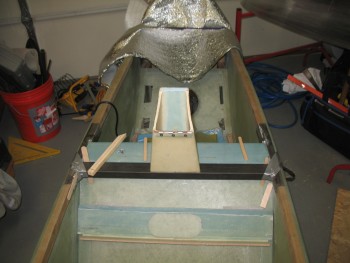

Here’s the cross bar trimmed & inserted into place.

Here’s the cross bar trimmed & inserted into place.

I then mounted the headrest (lower half) back into place with the aft bolts.

Here’s a side view of the remounted headrest.

Here’s a side view of the remounted headrest.

I then opened up an extra long 1/8″ drill bit I picked up specifically to drill the front mounting holes for the headrest, that will attach it to the cross bar.

Here’s the drill bit ready to go!

I marked the target drill points for the front headrest mounting holes.

And then used the extra long 1/8″ bit to drill the front headrest mounting holes.

Once I had drilled both mounting holes, and confirmed that I had drilled into the cross bar, I removed the headrest.

I then drilled out the initial 1/8″ holes to 3/16″, and test fitted the holes with a couple of AN3 bolts.

I then turned my sights on the cross bar.

I drilled the 2 spots I had marked by drilling my initial headrest mount holes with the 1/8″ long bit.

And repeated the process a couple times with thicker drill bits, ending up with 1/4″ holes.

I then clamped a K1000-3 nutplate to the surface, and drilled out the first rivet hole.

I then inserted a rivet on the just-drilled side, re-clamped the nutplate & drilled the other rivet hole.

With the right side holes drilled for the headrest mounting hole, I repeated the process for the left side.

Resulting in 2 set of holes for the headrest mount nutplates in the cross bar.

Resulting in 2 set of holes for the headrest mount nutplates in the cross bar.

I had originally considered using flush mounted rivets but it would have been too difficult, so I simply used Cherry Pop rivets to hold the nutplates in place.

And tested the nutplates by quickly installing a couple of AN3 bolts.

I then mounted the headrest to the cross bar, or I guess at this point in time I actually mounted the crossbar to the headrest.

I placed the top of the headrest back in place and the lower seat back in place as well to get an idea of how the seat back, headrest & rollbar looked up to this point.

I placed the top of the headrest back in place and the lower seat back in place as well to get an idea of how the seat back, headrest & rollbar looked up to this point.

With everything looking good, it was time to focus on the seatbelt mounts. But before I moved forward with mounting the seat belt reinforcement inserts, I wanted to verify the positioning of the upper seat belt mounts.

With everything looking good, it was time to focus on the seatbelt mounts. But before I moved forward with mounting the seat belt reinforcement inserts, I wanted to verify the positioning of the upper seat belt mounts.

I grabbed the wood mock cross bar & screwed the upper seatbelts to my initial, proposed mounting locations. I climbed into the fuselage to check the fitting. All seemed good at first, but after moving my head around & moved around as if I were leaning to each side to look out of the canopy, the inside edges of the seatbelts were scraping the side of my neck. Not bad, but I decided to move the seatbelt mounting points outboard a mere 0.150″, so I remounted the seatbelts & it seemed to do the trick. Clearly if I move drastically to one side of the fuselage, I’ll get a belt in the neck. But for normal ops, moving the seatbelt mounting locations out just a tad seems to worked. BTW, as I’m sure many of you know, the original plans positions received a few bad reviews for being too far outboard & not fitting so well on the pilot’s shoulders.

With my new seatbelt mounting positions in hand, I started drilling the cross bar for the seatbelt mount reinforcement inserts [7/16″ SS bar drilled with a 1/4″ hole].

With my new seatbelt mounting positions in hand, I started drilling the cross bar for the seatbelt mount reinforcement inserts [7/16″ SS bar drilled with a 1/4″ hole].

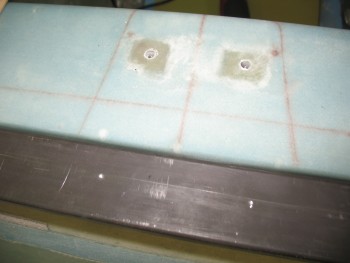

I got the holes drilled: 3/8″ on top to provide a positive stop for the seat belt bolt & 7/16″ on the bottom to allow for the installation of the reinforcement inserts. I then test fitted the left side seatbelt mount reinforcement insert.

I got the holes drilled: 3/8″ on top to provide a positive stop for the seat belt bolt & 7/16″ on the bottom to allow for the installation of the reinforcement inserts. I then test fitted the left side seatbelt mount reinforcement insert.

The cross bar from the bottom with one of the seatbelt reinforcement insert in place.

The cross bar from the bottom with one of the seatbelt reinforcement insert in place.

And then tested the fitting & look of the 1/4″ seatbolt mounting bolts with their associated washers.

And then tested the fitting & look of the 1/4″ seatbolt mounting bolts with their associated washers.

So I clearly busted my March deadline to finish Chapter 8, but I’m very pleased with the progress so far. I estimate that it should only take a few more days to finish the rollover assembly.