Today I started out by heading down to a local restaurant, grabbing breakfast and consolidating my current three 3×5 card task lists into a single task list. With my list consolidated I was motivated to get to work. As I was leaving the restaurant I got a call from an old friend. It’s always hard to not talk to friends or family that I haven’t heard from in a while, so I chatted a bit. Well, I’ll be darned if that didn’t roll right into another call from yet another old friend. My though was that I have to accept the fact that most people only have time to really chat during the weekend . . . . so I chatted some more.

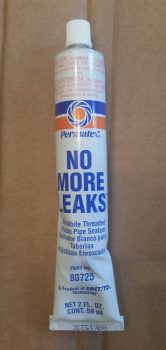

A bit later, I checked the mail and found the Permatex 80725 Plastic Pipe Sealant that I ordered was delivered quite ahead of its stated delivery date. Up until last week I was simply considering using pipe tape to install the ELS-950 sump low fuel level sensors, but after further thought I decided to order the sensor manufacturer’s recommended Permatex 80725 to better ensure no leaks. To be clear, as a function of the low fuel level sensors they must be situated below the high fuel mark, making the ELS-950 sensors installation seals critical to having no fuel leaks.

With my preparing to install the sump low fuel level sensors, I needed to create wire labels for both the sensor wires and the GIB LED floor lighting wires that are located in the sensor covers. Besides just wanting to keep my wires identified, in this situation it’s even more vital since all these wires are hidden away for the first 12-18″ and ascertaining what wires go to what would be much more difficult without wire IDs.

With all the obvious effort I’ve done on my electrical system, this little ditty here shows how extensive the task is: As I was listing out my wire labels to print I realized that I didn’t have enough consolidated information on exactly what component power wires connected to my power busses at which tabs. With the addition of a few extra unexpected electrical components over the past 6 months –including these low fuel sensors– it’s really too easy to lose sight of exactly what power wires feed from what buss, and exactly what tab a specific wire may get connected to.

Thus, yes, another unintended and unexpected task reared its head… I determined that my sheet of notebook paper with the Main, Endurance and Battery power buss connections listed on it just wasn’t enough. I needed it in electronic format as a worksheet in my electrical system spreadsheet, so I made that happen. Then I spent a few hours inventorying every instance and every wire that connects to a power buss, including each buss’s threaded feed stud.

Besides the information listed on my tattered notebook sheet, I did an accounting for the already labeled tabs on the physical ATC fuse busses. I then went through literally every wiring diagram to account for every listed power buss connection in the diagrams. I then went through my components list to ensure that the power feed for every electrical component going into the plane was accounted for. Through all this I found some discrepancies in the required fuse sizes. Finally, with a complete accounting of all my buss power connections I was able to reorganize some connections on the respective buss tabs.

I then printed out a number of labels. Unfortunately, with all my above shenanigans I simply ran out of time, and energy, to start on any major shop tasks.