Knowing that my lathe was getting delivered today and that I needed to sign for it, I started by opening up the shop and got busy wet sanding the very front NG30 mini-bulkhead that I clear coated last night.

After wet sanding it I buffed it out with rubbing compound and then hit it with a couple coats of polish. It’s not perfect by any means but I think it will look great as a part of the white center NG30 “console”.

Then the UPS guy showed up with my lathe. Which came in 2 separate boxes. [I’ll warn you now that the rest of this blog post pertains to the lathe, so if you’re not interested you can shut this down now…. cheers!]

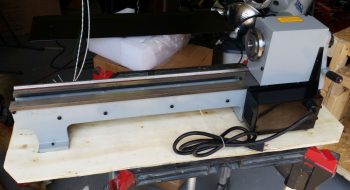

Yep! It’s a lathe!

Two big benefits of getting this specific lathe was that A) it was actually in stock, and B) the reports on it NOT being delivered in a mangled, unrecognizable container were non-existent. In fact, the feedback was that it was packed VERY well for shipping (Two boxes vs just one greatly verified that fact).

Box #1 contained the main body: the headstock and the bed (aka rails). It also contained the chip pan.

I then pulled the rather heavy headstock and bed assembly out of box #1, still mounted to its wood shipping mount plate.

I then opened up Box #2. Words can’t express how pleased I was with the packing quality of these components. The foam here was not cheap styrofoam, and the overpacking was just off the charts.

Box #1 of Box #2 was the gear cover that mounts to the left end of the lathe to cover all the gearing on that end. Now, the motor is a direct belt drive configuration, but the ancillary lead screw drive and threading is gear driven.

Here’s the outside of the left end gear cover.

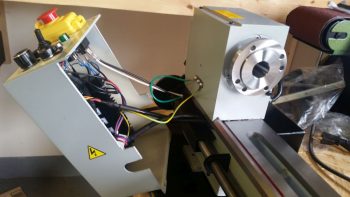

Box #2 of Box #2 was the electronics box.

The outside of the electronics box is the front of the lathe and the top is the control panel.

Then there was the odd components: the rubber mounting feet brackets and bag of accessories.

A closeup of all the threading gears in the bag of accessories. This bag also included all the hardware and handles.

The rear back splash was honestly the only “free’ floating component packed in Box #2.

With all that stuff that came out, and there was still 2 boxes left to go in Box #2.

And again, the overpacking and protection was spot on!

One of the boxes contained the Compound slide with the old style tool holder attached (this will get swapped out for a quick change tool holder).

The top view of the Compound assembly.

Here’s the cross-slide assembly underside.

And the top side of the cross-slide assembly.

And let’s not forget the 3″ chuck (that I’ll most likely never use).

Here we have the headstock, the bed, the tailstock, the compound and cross slide. I should note that as all these metal parts were unboxed I cleaned them with solvent.

I then flipped the headstock and bed upside down to remove the wood shipping mount plate.

And then mounted the chip bed and feet assemblies.

I then set the lathe assembly in place on the work bench.

And started wiring up the electronics box.

A closer shot of the electrical wiring getting connected out of the electronics box.

As I was checking the operations manual I ran across a template with the dimensions spelled out to hard mount the lathe to the bench. I liked this idea much better so I removed the rubber feet and spent well over an hour (my issues, not the machine’s) getting it mounted to the bench. In the end, I like this configuration MUCH better… a lot more stable.

To see the lathe in action and overview of my latest tooling up, I created a fairly short video:

This will be the last post I make for almost a week as I pack up another load to head down to North Carolina. For any curious types out there, I should be down in NC by the end of the summer. After settling in I plan to stop offering up these silly excuses as to why my plane is not finished yet!

Welcome to the dark side Wade.

The pull … too much … I …. can’t ….. resist . . . .

(hahaha!)

;)