Another 2-day post here.

While I was able to get a good build on the aft bottom corner of the canard (I would say it was 1/16″-5/32″ low), it took a couple good slatherings of micro to get there.

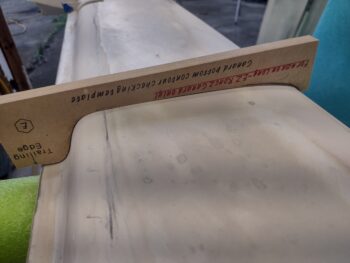

And while the majority of the underside canard was good, I still had some decent sized divots and still a few low areas that need a third round of micro fill. Here is the 3rd and final micro fill on the bottom of the canard… after nearly 6 hours of minutely checking the bottom canard surface against the template, about every inch down the canard.

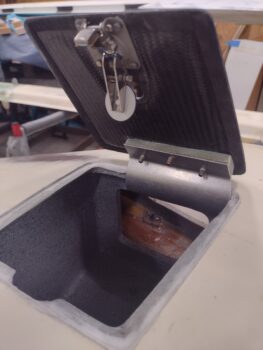

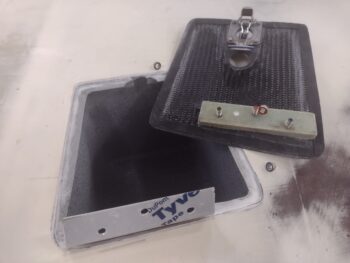

I also did a significant amount of work in finalizing the strake storage compartments, with most of my completed tasks on the right side.

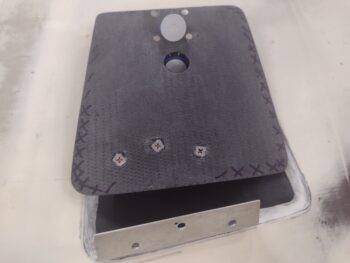

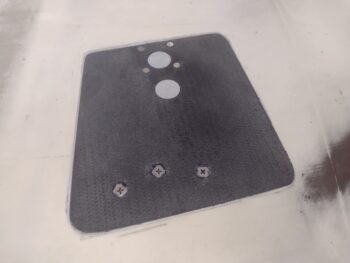

After getting the hatch door level with the surrounding strake surface, I then swapped out the bolts I’d been using for shorter CS screws. I then notched the edge of the screws, countersunk the 3 holes and floxed the screws not only to the carbon fiber hatch door, but also to the hinge spacer as well (itself floxed to the underside of the door).

So although I’m using screws, this allowed me to mimic the left strake hatch door by making it removable… via some “Poor man’s Clickbonds.”

I then did 3 iterations of marking the edges of the right strake hatch door where it was higher than the strake surface, then removing the door and sanding down the edges.

Again, after 3 rounds I was able to get the door even on all sides, level with the surrounding right strake surface.

I then did the same thing on the left strake hatch door, with it now level with the surrounding strake surface (except for the inboard aft corner, which is low and will need some minor micro filling).

Here we have the bottom of the canard with the last cured micro fill sanded and ready for epoxy wipes. It’s a great feeling knowing that my canard is finally up to Roncz specs with its contour matching the template.

Tomorrow I plan to press forward in getting the top side of the canard squared away.