Chapter 25 – Finishing Canard

14 April 2015 — It’s quite the rainy day in the Nation’s Capitol today. I took some time this morning to do some research on my sandblaster woes. I found out some great info, and as often is the case with Harbor Freight equipment there is a hidden set of gotchas that comes with it . . . awesome, cheap prices, but many times at the expense of having to incorporate some type of workaround.

Thus it is with my sandblaster. Even though I have an air dryer for my compressor, it is old and probably performing far below what it should be. At some point I’ll get a new desiccant filter for my air dryer, but to get moving quickly on this project, I simply bought an inline desiccant air dryer, along with an inline filter, while I was out buying a myriad of things for the next phase of this build. I’ll need to track down a few more things like higher end ball valves if I want this sandblaster to perform for a good period of time. I did hold off on buying any more blasting media until I conform my upgrades work. One last thing on the sandblaster: I learned that there is a definite trick in the order to which the 4 ball valves get opened, and exactly how far to open each of them to keep the media flowing, and not jamming up in the hose.

In addition, I bought some 12 ft long 2×6’s to use for the canard work bench that I’ll be building within the next few days.

Finally, as you may get a slight glimpse from the picture above, I spent over 2 hours last night doing nothing but cleaning & organizing the shop and putting all my tools back where they belong. With that, the start of the finishing of Chapters 10 & 11 looms ever closer!

•••

15 April 2015 — Since it wasn’t raining today, I started out today by picking up some particle board. I decided to use only regular wood, so I also bought another 12 ft long 2×6.

I checked both 2×6’s with my aluminum long board straight edge to confirm that they were straight. I have to say, they were both spot on. I was actually prepared to break out the table saw to trim the edges to ensure they were even, but luckily didn’t have to.

I set up my adjustable saw horses in the side yard in preparation for cutting the particle board.

I then placed 2×3 stringers on top to allow clearance for the saw blade & to support the cut halves of cut particle board sheet.

I hauled the sheet of particle board from the truck to the sawhorses.

And measured & marked the cut line with a chalk line.

I then grabbed the caged “Beast” . . .

And unleashed it!

And cut the particle board sheet right down the middle.

I then started cutting the cross support struts for the work bench.

I pulled the canard down from its storage location on high.

One idea I had to get the fuselage tucked out of the way while I work on the canard is to simply build a tall-enough work bench to stow the fuselage underneath.

I put the fuselage on furniture dollies & strapped them with tie-downs to keep the fuselage in place. This simple task made moving the fuselage amazingly EZ & was really helpful in getting the shop squared away.

I then started building the canard work bench . . .

I screwed the cross support pieces into place.

And then screwed the top pieces onto the work bench frame. You can see below that the fuselage fits fine underneath the canard work bench.

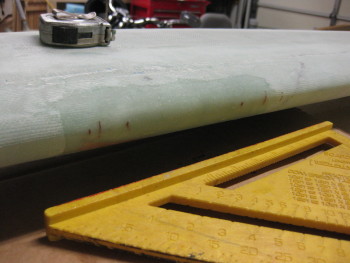

I then set the canard on the bench to see how much room I have to work with. It’s still amazing to me how long the canard is. Even with a 12 ft long table, there’s just enough room to work on the canard.

•••

24 April 2015 — I put this post under both chapters 10 & 25 because prepping the surface of the canard is a prerequisite for not only finishing the canard, but to glassing the canard “swoosh” tips to the canard & in optimizing the elevator install process.

How? Well, in yet another discussion with Randi from the infamous Cozy Girrrls, she highly recommended finishing the bottom side of the canard BEFORE mounting the elevators to exponentially decrease the time & effort it takes to finish the bottom of the canard with all the elevator mounting tabs in place. In addition, it helps knowing what the bottom contour of the canard will actually be when determining the spacing between the elevators & the aft edge of the canard.

As per Wayne Hicks, and so many other Canardians, I decided that the easiest, less-destructive route for prepping the surface of this plane for finishing would be sand blasting. It’s faster and clearly it can prep the fibers that lie slightly below the surface as compared to the “taller” fibers without having to destroy the strength & integrity of the outer fibers–as one would have to do if sanding the surface in preparation for finishing.

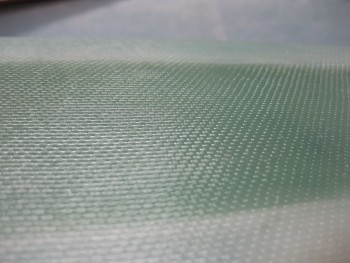

I personally find the texture, gleam & appearance of well laid-up glass (above) wonderful, as I’m sure a lot of other folks that work with fiberglass do as well. But of course this surface can’t remain for the final finish, so we must often cover up some of our best work (and thankfully our not-so-best!) under micro!

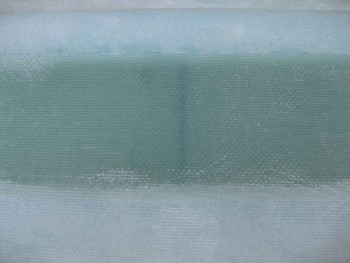

I wanted to add this shot below for my fellow builders who don’t use MGS. I still am impressed by how a line drawn on the shear web can still be seen after ~10 plies of 3″ UNI tape have been laid up over it. As a user of MGS, it will be especially interesting to finish the surfaces of these “transparent skinned” components into a solid-colored airplane.

As I’m sure most of you are aware, I had some definite sandblasting woes when trying to sandblast the rollbar before priming it. I have since done a lot of research and am hoping that I can get this sandblaster to work well enough to finish at least the canard, then I can reassess.

I started by taping up the antenna leads to protect them from any errant sandblasting.

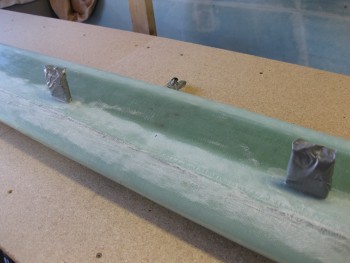

I then did the same for the canard mounting tabs.

One issue that I wanted to avoid that was a possible contributor to my sandblasting woes was ensuring that the air I was using was CLEAN & DRY. I bought & employed a couple of inline filters & combined them with the appropriate air connectors into an assembly that I jokingly called, “the Kraken.” I then mounted the Kraken to the air inlet on the sandblaster.

I then employed all the tips, tricks & processes that I had learned about this somewhat cheap sandblaster, and although it’s still not a pleasure to use, it at least gets the job done now. You can definitely tell the areas that were sandblasted & those that weren’t.

Just as Wayne Hicks described his sandblasting experience on his Cozy IV build site, the sandblasting textured the canard surface perfectly and didn’t damage it in any perceptable way.

Thus, stopping every few minutes for both the compressor to re-build up pressure, and clearing out the subsequent plugged-up nozzle from the decrease in pressure, I was able to knock out the bottom right side of the canard in about 40 minutes. With a bigger, higher quality sandblaster I’m sure I could have cut that time in half, but I’m more than happy with the time, effort & cost required to attain the results that I did.

Another technique I employed in optimizing the sandblaster’s ability to simply work was to bring my compressor out to the job site. Instead of running 2 lengths of air hose, I simply used one. The first time around I used 2 hoses, with one of them being rubber. Apparently rubber hoses allow much more moisture buildup, as does longer lengths of hose.

So somewhere in both using the correct sequence in the opening of the 4 valves on the sandblaster, and the corrective measures I took to ensure clean, dry air, I was able to sandblast the entire bottom side of the canard.

At one point fairly early on, I did have to empty the sandblaster of all the media and fill the sandblaster hopper with smaller amounts to keep it from clogging up. But again, that was a minor annoyance in comparison to being able to sandblast this thing on the cheap.

Since it started getting dark, on the topside of the canard I simply sandblasted the edges at the inboard areas where I will need to finish the canard, and the glass covering the outboard extensions which need surface prep for the upcoming glassing of the “swoosh” tip extensions.

All the sandblasting I accomplished today on the canard actually meets all my requirements for completing chapters 10 & 11. However, I will finish sandblasting the top of the canard since as I mentioned before, my plan is to actually finish the entire canard & elevators to paint.

•••

1 October 2015 — Yesterday and today I’ve been pouring over my project to-do lists, plans and tasks in order to get back on track with the build. After spending hours re-covering specific steps in the Long-EZ Plans Chapter 10, the Roncz canard plans, and the Cozy Girrrls instructions on their elevator actuators, I then went back over my notes on finishing the canard with micro, sanding techniques (mainly Wayne Hicks’ methods), etc.

My first order of business, after cleaning & organizing the workshop a bit, was to find all the templates related to the canard and elevators. That took maybe 5 min since luckily I had the box in which they resided in sitting on the work bench. Hey, sometimes I guess I am a little proactive!

My next task was to clean all the goop off the “K” canard mounts to allow them to be reused while finishing both sides of the canard. I spent about 15 with a razor knife cleaning up the crud to allow for a fresh clean canard mounting.

After calculating the distances between the 5 “K” mounts I’m going to use, I then mocked up the canard upside down on the “K” mounts to ensure a study platform on which to finish the bottom side of the canard.

Now, if you’ve seen Wayne Hicks’ webpage on how to finish the canard, then you’ll know that he uses a 3-4″ wide sanding block which is essentially nothing more than a widened contour template that is adjustable in height and which a wide piece of sandpaper can be attached on the inside of the contoured area. Well, on his site Wayne explains that you can’t finish the bottom of the canard using the contoured sanding block setup because of the multiple installed elevator hinge mounts that get in the way.

So, a few years ago when I was talking to Randi (aka “Cozy Girrrl”) she gave me a ninja tip to finish the underside of the canard first, then not only would I have a more concise measured gap between the aft tail of the canard and the front of the elevators, but I would also have eliminated a lot of pain & strife trying to finish that bottom of the canard with those darn elevator hinge tabs in the way! Plus, not only would the finish look much cleaner & nicer, but it would be more aerodynamically correct. A win-win if you will.

One last thought on finishing the bottom of the canard now, is that as simplistic as it sounds, it will be finished. And since I plan on finishing the entire canard & elevators before storing it away until later, it will be one less thing I have to finish when I “hit the wall” that is Chapter 25 (aka “Finishing”).

The first actual step that I needed to complete was repairing the Leading Edge of the canard. You see, back when I glassed the canard as I was pulling the duct tape off the leading edge after the bottom skin had cured, it pulled out a pretty big chunk of the leading edge blue foam underneath. With the canard being upside down, and with some foam missing under that 4″ leading span, the bottom skin glass naturally depressed a little right in that area as it cured. When I flipped the canard to glass the top, I had to back fill micro behind that 4″ deformed area on the LE to account for the missing foam.

When I did the glass layup on the top of the canard, I could tell that I was going to have to repair that damaged LE area later on by adding a few plies of glass. To “mark” the LE area that would required repair, I simply peel plied it. The peel plied area on the LE was thus my marker for the future on the exact area that needed further work.

Well, the time to repair the canard LE has finally come . . . after about 2-1/2 years since I finished the canard. (Wow, time flies!)

I took a straight edge to the front of the canard to get an idea of how much glass to add. I determined I would only add two plies of BID: a) 3/4″ x 4″ and, b) 1-1/2″ x 5.2″. These would give me just enough glass fill that, after sanding, the remaining surface irregularities would easily be filled by the finishing micro.

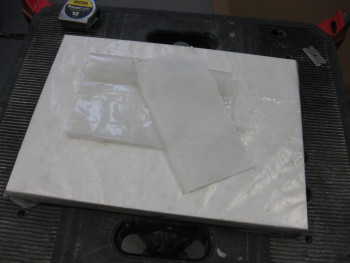

As per my usual, I will pre-preg this layup so I cut out a small piece of plastic and prepped my peel ply.

Before getting started on my new build quest, I had to reload both my stock of micro and flox, each container being almost completely empty!

Below is the freshly laid up 2 plies of BID.

Below are a couple shots of the finished layup peel plied.

Below are a couple shots of the finished layup peel plied.

As the LE patch cured, I started working on the canard lower contour sanding block.

A few hours later I pulled the peel ply off the 2-ply BID patch.

And then tested the patched LE area against a straight edge. There are still a few minor irregularities, but nothing that can’t be handled with a little bit of sanding and some micro during the finishing process.

•••

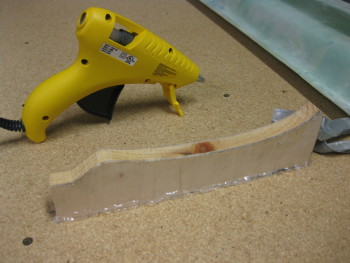

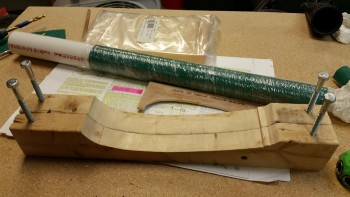

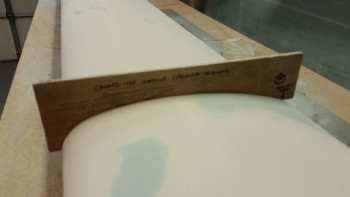

2 October 2015 — This afternoon was all about making the sanding block for finishing the underside of the canard. As I described before, this sanding block is nothing more than a 2-3/4″ thick version of the “F” contour template for the Roncz canard.

Yesterday I showed a quick pic of the results of my grabbing a 2×4 out of my scrap pile and tracing the “F” contour template on it. Once the outline was traced, I used a dull pencil to retrace the line to allow for the actual thickness of the sandpaper once attached to the contour sanding block. BTW, Wayne Hicks used wider sandpaper than I will be using, but since all my 4″ wide sandpaper is attached via velcro, and my narrower 2-3/4″ sandpaper strips are attached via peel ‘n stick, I figured I would go with the cheaper/narrower peel ‘n stick to start out. If need be, I’ll change this later on.

Again, yesterday I cut two pieces of a scrap 2×4 to length, and then ripped one of them lengthwise to get the correct width, once the two 2×4’s are joined, to match the sandpaper width.

Today I clamped the 2×4 pieces to my “new” table saw as a work bench and used my jig saw to cut the contour profile. [SIDE NOTE: A friend of mine called me up & asked me if I wanted this table saw as she was getting rid of it because sadly her dad passed away. I was wanting a cheaper table saw to use to rip the metal engine mount extrusions since I was really not comfortable doing this on my nicer table saw. I tested this table saw on these 2×4’s, and so far it works like a champ.]

Here’s the result on 2×4 piece #1:

I then transferred the outline of the first (narrower) 2×4 piece to the second 2×4.

After the profile shape was cut into 2×4 #2 I then clamped the two sides and screwed them together. I then cut and attached a piece of sandpaper to the contour of the sanding block. With the shop at about 70 deg F, I noted the sandpaper was having trouble sticking to the more curvy parts of the contour. I used the heat gun to warm up the sandpaper’s adhesive backing a little, but even after that I’ve come to the conclusion that I will probably have to use 3M 77 adhesive spray to really get it to stick.

Hmm, maybe a good argument for using the velcro-backed sandpaper?

Here’s a shot of the finished product sans “legs”.

To give this project some legs (yuk, yuk), I drilled a pilot hole in each corner and screwed in a 5/16″ lag screw (I think… don’t quote me on actual size since they were merely sitting there conveniently in my tool bin). Each lag screw is 3-1/2″ long which will be good for the starting height I’ll need once the canard is mounted.

And here’s a quick shot of the finished contour profile sanding block for the underside of the Roncz canard. Tomorrow, I plan on hard mounting the canard to the table and “K” blocks and then getting to work on finishing the bottom of the canard.

In prep for finishing the bottom of the canard, I marked the canard about 1.2″ inboard of each end to show me the point where I need to stop the micro finish on the lower canard surface. The reason for this of course is that the Roncz canard swoosh tips require 1″ of glass overlap onto the canard ensure that they’re solidly attached.

•••

3 October 2015 — Early afternoon I went to Home Depot to pick up some supplies to start the micro finish on the bottom of the canard.

Shortly after I returned home, I met future Long-EZ builder, Sohail, and showed him around my shop, and all the various pieces parts of my Long-EZ project. Of course what ensued was a long conversation on building Long-EZ’s, canards, and airplanes in general.

After Sohail left, I worked on getting the canard mounted upside down on the workbench. Thus, my first order of business was to secure the “K” mounts to the workbench surface.

I had thought about either hard-mounting the “K” mounts with screws & maybe some brackets, but I really wanted to minimize the holes in the workbench top. Plus, all but one of the “K” mounts are made of particle board and I didn’t want to add any stress to them by drilling holes, etc.

Another option was of course bondo, but I didn’t want the mess, the smell or the pain of sanding it off the workbench surface after removing the “K” mounts. As you can see by the pics, I went the hot glue route. Hot glue has plenty of strength for the job and it cleans up fairly easily.

After ensuring the “K” mounts were aligned & spaced properly, I hot glued them to the workbench top.

•••

4 October 2015 — Today I undertook my first official act of finishing a surface on this Long-EZ. As I mentioned before, I re-read the notes & material I had on finishing to brush up on this endeavor that apparently seems to be half science and half art.

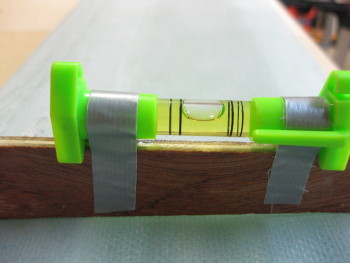

I started out the morning by confirming the side-to-side slant of my workbench so I would know how to position the canard to match the workbench surface. My first thought was to simply use cargo straps in the center area of the canard, but after playing around with the whole setup I realized that the “K” mounts weren’t entirely even (how I had placed them, and they were now glued to the table… I believe this is in concert with slight differences with the top surface of the canard as well). This meant that the contacts between the underside (actually the top) of the canard as it lay here was not in perfect contact with the “K” mounts. When I tightened the tie-down straps on each side of the mounting tabs, I was getting all kinds of weird angles due to the force down on the center of the canard, making the outboard areas seat differently on the “K” mounts.

After playing around with the straps for about 30 minutes, I realized that I had to call “no joy” on this method and resort to something I really didn’t want to use: Bondo.

I spent about another 45 minutes working to get the canard to lie naturally on the supports without any stress from the top (technically bottom canard surface) of the canard in this position. Since the spar cap may be higher on the aft side in one area of the canard and then higher on the forward side 2 feet down the canard, there are a myriad of tiny surface variances that affect how the level attached to the “E” template will read. I spent a lot of time figuring out where my “normal” areas were that I was getting good readings, then I found the locations that had weird readings for any surface anomalies rearing their ugly head.

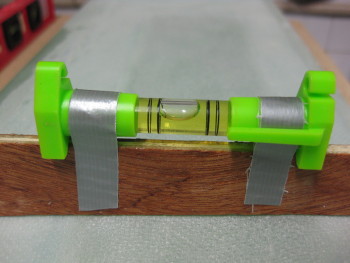

Again, I started with my digital level crossways on the table, as well testing my little bubble level that I taped to the top of the “E” template.

Below is the “E” template at the far Right side of the canard, the middle of the canard, and on the Left side of the canard (of course all underside), respectively. As you can see, the bubble is situated in pretty much the same spot on all of them.

Happy with the position of the canard, I went about the nasty task of Bondo’ing the canard to the “K” mounts.

After I was finished with the Bondo and as it cured, I took my Bottom-side Canard Contour Sanding Block outside and shot it with 3M Super 77 spray glue, along with the actual backing of the sticky sandpaper. Since it takes a bit of time for the spray glue to set up, I went ahead and weighed the sandpaper down to get it to lay correctly in the contoured area.

After messing around with getting the sandpaper weighed down, I went back to the canard and spent about 5 minutes double checking that its angle & elevation were correct in relation to the workbench. Thankfully, it was.

And below are some shots of the Bondo holding the canard in its correct position.

With the canard nice, snug & secure, I took one last opportunity to sand the LE overlap glass seam and any other overly bright & shiny spots. After my sanding spree, I vacuumed up the mess and then cleaned the canard surface with an incredible effective cleaning solution: water!

With the canard set to go, I then pulled the West epoxy out of the hot box and gathered up my West epoxy system pump set. This was going to be pretty fun to use this since the last time I messed around with these pumps was when I took the EAA Composites Course in January 2011.

I got my epoxy workstation situated and primed both the epoxy and hardener pumps so that when I pressed on the pump handles I actually got the correct amount of epoxy or hardener per every stroke.

Now, I am grateful that my first time out using micro for finishing was on the BOTTOM of the canard, since clearly it’s not as uber critical in shape as the top. Of course that’s not to say I’m allowing shoddy workmanship, since, yes, I realize that the canard bottom surface & elevators are essentially Fowler Flaps, and clearly the bottom surface shape is important too.

I’ll also admit that in attempting to follow the letter of the micro-finishing law that states that thou shalt use the driest micro possible, after spending 10-15 minutes trying to lay down really dry micro I realized that it was just not working. I scraped off micro set #1 and it went into the trash.

After my on-the-job micro lesson in round one, I simply wimped out and went with only dry micro for the next round. Amazing what half a cup less of micro in the mix allows one to do! I may have cheated a hair, but let me tell you, the ability to actually get the stuff to stay on the surface was an awesome feeling . . . and trust me, that doesn’t mean I’m saying it instantly turned easy. It just went from being an impossible task to an actual possible task, albeit still really challenging (read: PITA!). I will say though, that with each batch of micro that I laid down I could tell I was getting a better feel for it and my micro-finishing kung fu skills were definitely improving. Here’s the round 2 stuff:

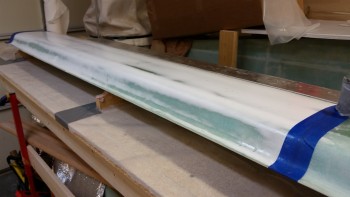

And with all that, Voila! Here is the micro finished underside of the canard, in all it’s glory! (Do you hear something? . . . Are those horns sounding?!)

After the micro cured for a couple of hours, I followed Wayne Hicks’ advice, who in turn was following Nick Ugolini’s advice, and I started sanding the canard to knock down the high, ugly stuff while the micro was in the “green” stage. This meant that having only cured for a couple of hours, the West epoxy was still a little rubbery, and thus much more easily sandable than fully cured micro.

Below is a shot of the underside of the Left side of the canard after I tackled sanding the micro in its “green” stage.

And here’s a shot of the underside of the Right side of the canard after I sanded the micro in its “green” stage.

Tomorrow I’ll sand the micro after its cured completely, using the contour sanding block (of course!).

•••

5 October 2015 — Before I changed into my full grunge sanding clothes I ran out to  Harbor Freight to pick up some finishing supplies. Instead of using the construction-type wall mud compound taping knife for applying the micro finish, I wanted an applicator with a low profile handle vs. the one long center handle. I found exactly what I was looking for in the automotive section with the Bondo applicators.

Harbor Freight to pick up some finishing supplies. Instead of using the construction-type wall mud compound taping knife for applying the micro finish, I wanted an applicator with a low profile handle vs. the one long center handle. I found exactly what I was looking for in the automotive section with the Bondo applicators.

Upon returning home, I got to work on sanding the micro’d bottom of the canard. I quickly realized that I have plenty of micro on the surface. I’m fairly certain that I’ve definitely met the “it’s better to have too much micro than not enough” criteria for finishing Long-EZ surfaces. The micro build is fairly thick, and although it may take an extra hour or two to get the surface sanded down to the right depth, in the long run it will be worth it since it will minimize rework & refilling.

The contour sanding block worked well. I can see where another inch in width would make it just a hair more stable in tracking the surface, but the advantage of the slightly narrower sanding block (as compared to Wayne Hicks’ 3-3/4″ wide block) is that I would think that the effort is much less to work it since there’s less sanding surface area. I can see where it would be nice to have a wider sanding block towards the end of the sanding cycle when the finer, higher grades of sandpaper are used.

I taped the small level to the top of the sanding block to give me a general idea at all times how the block is angled compared to the table, and in turn the bottom surface of the canard.

Below is a shot after the first few passes on the lower Left side surface of the canard.

And another shot after multiple, multiple passes and about 4 lowerings of the sanding surface.

I was happy with the progress, but one minor issue I found is with the relatively high build in the fishtail area of the TE as compared to the lower build of micro on the front LE area. This difference in micro thickness resulted in an affect where the natural flow of the contour sanding was resulting in the LE getting more abrasive action initially than the TE. In other words, I was either fairly close or already down to LE glass up front with still a relatively decent amount of micro to remove in the TE area. Part of this issue was the good amount of micro build I had on the entire bottom surface of the canard. I simply have to get through both the bottom surface buildup of micro before the contour sanding block really starts cutting into the micro on the TE’s fishtail trough, thus, alleviating the current unbalanced cutting action of the contour sanding block.

Since I had pretty much killed the first piece of 36 grit sandpaper on my contour sanding block (I should say 3 distinct areas of the paper), I set aside the contour sanding block and decided to call in backup. I pulled out the mo-jamma rigid 30″ x 4.5″ 3M marine sanding block (also recommended by Wayne Hicks) with 36 grit sandpaper. I worked each side for about 15 minutes each in the standard 45° to the left, then 45° to the right pattern.

I used some fairly hard pressure and was amazed at how tough that micro is after its cured. But I could tell by the significant amount of micro powder that I was producing that the long block was doing its job.

All in all I spent about 2.5 hours sanding yesterday, and have at least that much more to do tomorrow to get this thing into the shape I need. I’ll start with the long block again tomorrow to knock down a fair amount more of the micro build and then switch back to the contour sanding block.

•••

7 October 2015 — I wasn’t able to get around to sanding the canard yesterday… but I was today! I started out by reinforcing the workbench by adding a 1×4 cross support between the two table supports.

I then started back sanding the canard with the marine long block with 36 grit paper.

After I used the long sanding board, I used the contour sanding block with 36 grit paper. I could tell by the sandpaper cut patterns in the micro that there was entirely too much micro build along and above the spar cap area, both on the left and right side of the canard. I marked across the width of these prominent gouge line areas with a Sharpie so that I could use the long board to remove the excess micro above the spar caps.

Here’s an “action shot” with the long board!

About 80% done here . . .

And voila. I repeated this process –alternating between contour sanding block and long sanding board– a couple more times to remove micro from above the spar cap area on both sides of the canard. This process did essentially two things: 1) It changed the profile of the lower canard to more closely match the “E” contour template by flattening the bottom of the canard and greatly decreasing the existing curve of the lower canard profile. 2) It optimized the TE shaping. The flatter the canard bottom became and more in line to the “E” contour template, the more effective the TE edge portion of the contour sanding block became since it was able to contact that aft area of the canard more fully.

And here’s a shot of the process on the other side of the canard.

The canard after the second full round of sanding:

And a closer shot of the lower right side of the canard after tonight’s sanding.

I’m planning on applying epoxy coats to the canard bottom micro finish tomorrow… schedule allowing.

•••

8 October 2015 — Last night I had a fairly lengthy discussion with my buddy Mike Beasley on the finer points of finishing the composite surfaces on Long-EZs. In fact, at Christmas-time last year, Joe Caraggio went down to Georgia (does that make Joe the devi . . . hmmmm? Interesting, but I digress) to assist in Mike in finishing (as in micro) his bird. So, during my discussion with Mike I got both his take and a lot of what he picked up from Joe on finishing techniques.

In addition, after having met the venerable Terry Schubert (Editor of Central States Association newsletter) at Rough River, I’ve been leaning on his guru-ship as well to ensure I don’t muck anything up! Terry has been very generous in offering me advice & info that has greatly facilitated my build progress.

Let me reiterate: this is the first round of finishing that I’ve done (ever!) and obviously the finish is the one HUGE thing that people see right off the bat when they look at your airplane. It doesn’t matter if the underlying construction of your airplane is strong or weak, or that it’s a thing of beauty or crying out to be covered in gobs of paint to hide its hideousness . . . none of that is truly judged when your bird is sitting on the flight line somewhere. Again, what is judged is how the surface & lines of your airplane flow, and how smooth & glossy the finish is on your paint job.

Thus, I want to get this finishing thing right from jump street.

So let me get off my soapbox and on to the build! Today I started out by taping up the outboard and inboard edges of each side of the canard. The outboard edges need to be epoxy free so that I can of course glass on the Roncz canard swoosh tips after I’m finished installing the elevators. Once the canard swoosh tips get glassed in place, then I’ll finish them as well and blend them into the existing finish on the bottom of the canard, and the top of the canard too for that matter.

The inboard areas will get smoothed out and feathered into the non-finished interior of the canard. This middle area doesn’t get finished to save weight, since once the canard is mounted it remains ‘buried’ & hidden inside the confines of the fuselage.

Now, I performed a little experiment on the bottom of the canard with the next step of finishing. On the Left surface in the photo below (which is the Right-side bottom of the canard), I used the now standard traditional Cory Bird method of wiping on 5 separate applications of pure fresh West epoxy, with an approximate 2-hour cure time in-between. Just as you might cheese grate the micro finish on the surface of the component after it has cured for around 2 hours so that it’s in the “green” stage, so too we let the pure epoxy cure to a “green” state before adding the next round of epoxy.

Thus, the picture below is the first application of pure epoxy onto the finished & cured micro finish.

If the Cory Bird method is test subject A, then Nate Mullins’ Micro Skim method is test subject B. Nate claims on his site that Micro Skim really cuts down on the post-sanding effort after the skim coat is applied. After talking with Nate about this method shortly after he developed it, I figured I would try it out on my first skim coat endeavor to see if it really is easier, and if so, perhaps save a fair amount of time & effort in finishing my bird. The essence of Nate’s Micro Skim coating method is simply adding a little bit of micro to the pure epoxy. The amount of micro is way less than what you add even for a micro-slurry, but just enough to give the epoxy a little bit of thickness when applied to the surface of the finished part. Application is a little easier since you simply roll on Micro Skim with a foam roller, whereas with the pure epoxy skim coating you are using a squeegee to apply the epoxy onto the surface (to be clear, some builders like Wayne Hicks have used a foam roller to apply to the epoxy skim coat and then used a squeegee to skim the excess epoxy off the surface).

Thus I used Nate’s Micro Skim on the Right side of the canard in the pictures (which is technically the L-side bottom of the canard when mounted).

BTW, the resulting finish of the Micro Skim, not surprisingly, is much more grainy and opaque than is the pure epoxy skim coat. Again, the proof will be in the actual sanding & quality of surface finish after these two sides have cured and are block sanded.

Here’s a shot after 3 coats:

After applying 5 coats to each side (and also filling in the very outboard left aft “corner” of the canard with dry micro – see pic below) I waited for about an hour before pulling up the blue edge tape. Below is the Micro Skim side about an hour after the final coat was applied.

And here is the pure epoxy skim coat side about an hour after the final coat was applied.

Here is the entire bottom of the canard after being skim coated & micro skimmed.

Although these are technically the next day, I added these two pics after the surface was pretty much cured. Pure epoxy skim coat is on the left, micro skim method is on the right.

•••

9 October 2015 — After a little bit more information crosschecking on finishing steps & techniques, I headed for the shop to block sand the cured skimmed epoxy. Since I don’t have any specialized sticky back (PSA) or velcro (HookIt) 100 grit sanding sheets, I had to resort to the old style sandpaper sheets. This actually worked out pretty good since I grabbed a scrap block of blue wing foam about 6″ wide, 12″ long and 2″ thick to use as a sanding block. The 100 grit sandpaper wrapped around the foam so I could firmly grip the paper around the foam and still keep control of the foam block while sanding.

I started on the pure epoxy skim coated side and started sanding away in the 45° left and 45° right pattern. I’m learning that all the sanding during these finishing steps seem to start off with not much happening, but as you just keep working the sanding block you really start to see some results. Of course the most time spent on the underside of the canard is in the TE area. The multiple curves and angles make it a bit more challenging to get the fishtail area sanded thoroughly. But after I was finished, and just as Mike Beasley mentioned the other night, I couldn’t stop running my hand over the incredibly smooth canard surface. What a feeling to turn a raw glass surface into something that you know that once painted, will turn into a something stunningly beautiful.

All in all I was extremely pleased with the outcome. Although my initial failings in applying bubble free micro led to having a dozen or so craters on each side of the canard (this was due to applying too dry of micro after aggressively whipping a ton of air into the mix), it was a good learning lesson since I know now how well both skim coating and Micro Skim fill in some major surface defects in the micro.

After sanding the pure epoxy skim coat, I was eager to see how the Micro Skim was going to sand out. Well, just like the other side it started a little slow, but then starting sanding out a little more quickly than the epoxy skim coat. To be fair, I don’t think there was any clear winner here between the pure epoxy skim coating and the Micro Skim, since they both produced very acceptably nice results. I’ll still continue to experiment with these two methods, and I’m thinking as my finishing skills improve I’ll be better able to both tweak the process and ascertain the results.

My plan for tomorrow is to finish round 2 of sanding the canard with 120 grit sandpaper, and then finish sanding, prepping and micro-finishing the front top “corner” of the elevators to get them ready for mounting to the canard.

•••

10 October 2015 — I started out today by giving the epoxy skimmed canard a thorough sanding. First off, I was checking out the surface in the light and realized it was still just a tad too lumpy across the board to my liking. So I backed up one step and grabbed the marine long board with 80 grit paper to knock off some of those surface irregularities. I did a pass 45° to the right and then 45° to left on each side. After knocking down the surface significantly with the 80 grit paper, I hit the canard with 100 grit sandpaper two complete passes on each side and then I finished up with a couple of passes using 150 grit paper.

After the final sanding down of the epoxy skim coat & Micro Skim I vacuumed the canard and the surrounding area, cleaned the canard and let it dry before taping it in preparation to prime it.

As I posted earlier this year, I made a decision to use boat paint for the final finish on this Long-EZ. Unless it proves unsatisfactory I’m keeping with that decision due to low cost & ease of application. Here’s a shot of the opened can right before I started priming the canard.

Jamestown Distributors, the company who sells Total Boat paint products, recommends using Xylol/Xylene to thin the primer. Since I didn’t have any Xylene on hand, and only just learned about it by watching the how-to video on Jamestown Distributor’s website, I decided to make a lunch/Home Depot run. I carted the above pictured gallon of boat primer down to Home Depot and as I was shopping for various paint supplies had them shake up the can for me in their Über-duber mixing machine.

After grabbing a quick lunch & returning back to the shop, I thoroughly stirred the primer, mixed it with 10% Xylene and applied the primer to the canard with a foam roller.

Some of you may wonder why I’m priming the canard at this stage. Well, it seems there is a common difficulty in getting the gap between the elevators and the canard just right. Thus, I want the gap to be a known quantity before I start. I don’t want to declare that a 0.2″ gap is in hand only to find that when I finish the canard and elevators that it’s only a 0.18″ gap, just as an example. Also, as I mentioned before, I believe Randi from the Cozy Girrrls when she says it’s infinitely easier to sand & finish the canard bottom when there are not 6 protruding elevator hinge tabs sticking out of the bottom of the canard. And since I want to get the canard as smooth and as prepped as possible for paint, then the primer needs to go on before the elevators get mounted.

Below are two shots of the canard after the primer was applied.

I took this pic of the trailing edge just to provide a general idea of the straightness of the canard.

As well as this shot of the LE.

Here’s a shot of the canard after I pulled the tape and sanded it with 100 grit sandpaper. The specs sheet said it should be ready to fully sand after 90 minutes, but even about 2.5 hours later I could tell it was just a tad bit gummy. Since it wasn’t fully cured, I only focused on sanding the very bottom surface and left the fishtail TE area until tomorrow after it cures more fully.

Here’s a shot of the other side after having been sanded with 100 grit.

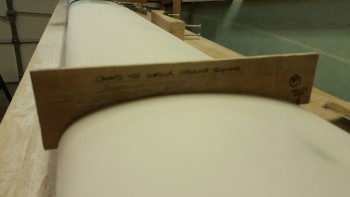

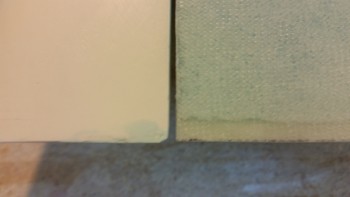

And a quick double check with the lower canard contour template showed that my lower canard is pretty darn close to specs. The TE is a just a bit high on the back end, but I confirmed with Feather Light years ago that this is within tolerance.

I then sanded the canard with 100 grit sandpaper. The next step is to re-sand the primer on the canard until it’s smooth.

•••

12 October 2015 — After a quick project update and Airdog Aircraft Factory tour for my neighbor, my next task was to give the canard’s primer coat a thorough sanding. When I last sanded it Saturday evening, by hand, I could tell this primer was pretty tough stuff. This time around I wasn’t going to mess around with the time consuming, more exhausting process of hand sanding, so I pulled out the big gun: my DA sander.

I started with 100 grit on the DA sander and hit both L & R sides. It worked like a charm and took no more than 10 minutes per side. I then follow that up with 150 grit paper on a pad sander, which I was able to use more effectively on the fishtail TE area. I realize when looking at the pics that there seems to be a fair amount of coated material in the TE trough area, but I would rather start from a normal application of finish material and have to remove more of it during the elevator mounting process (to meet the .2″ gap requirement) than to assume it shouldn’t be there in the first place and not finish the TE area, as I have seen some other builders do it. Not calling right or wrong, just a personally preference.

I vacuumed the canard surface and the surrounding area, and then pulled out the “L” templates for mounting the elevators to the canard.

A shot of the “L” templates mocked up in place.

With the bottom surface of the canard now finished to the primer, I don’t want to bondo anything (i.e. “L” templates) to the surface of the canard just to have to clean it up later & risk messing up the finish. For this reason, ala my friend Dave Berenholtz, I will simply keep the “L” templates in place by weighing them down.

So as I was out & about tonight I stopped off and got the materials & supplies required to make some sandbags. When I get those made tomorrow I’ll start on the journey of installing the elevators to the canard!

•••

16 October 2015 — I traced out the Top Canard Contour Template “E” onto one of the 2×3’s I used for cutting the blue foam swoosh tips and made the first half of the top canard contour sanding block.

I then ripped the other 2×3 to 1.1″ wide, attached the two halves, gave the interior working edge a good sanding to get the surface evenly matched, drilled the lag screw pilot holes and then mounted the lag screw support legs. As you can see below, the canard top contour sanding block is complete.

I did tweak the TE of the top canard sanding block just a hair so that my sanding of the canard top wouldn’t end up being a “let’s destroy the TE” party. Last week I traced out the actual-sized profile of the canard from the Roncz plans to double check my progress. And as per my discussion with Mike at Feather Light, you may be able to make out that my TE on the canard is definitely just a tad higher than the Roncz plans outline.

•••

24 October 2015 — Seriously, I did a ton of sanding on the canard today to prep it for finish, and yeah, I got the itch!

I set up my gear & took the canard outside to sand that sucker!

Below is a pic of how much of a mess I made by sanding the top of the canard. The pic below shows it all clean & ready to got back into the shop.

Once back in the shop I whipped up a fresh batch of micro finish using West epoxy to apply to the bottom surface of the canard. I’m starting back on the bottom side to blend in the newly added canard “swoosh” tips.

Here’s the shots of the inside rib of each swoosh tip:

Since I had time & micro finish on my hands after swabbing down the swoosh tips, I heated up the cup and applied the micro finish to the ice shields.

A few hours later after the micro “greened” I cheese grated it. All I have to say is Wow! Since I waited about another 45 minutes from normal time (2-3 hours vs my 3.5-4 hours… obviously YMMV) to cheese grate this thing, it worked like a champ. As you can see I got all the major bumps & grooves sanded out on these added canard tips.

And again, here’s the inside “swoosh” tip rib that also got micro’d & then cheese grated (both sides):

Finally, since I was working with a ton of micro finish, I also finished the various small parts I have in the works such as the ice shields and the GPS antenna cover from atop the modified headrest.

Here is an example of cheese grating vs not cheese grating:

And then when all are cheese grated:

Next, I’ll final sand all these parts and start in on getting 3-5 epoxy wipe layers on this stuff.

•••

30 October 2015 — I started off today intent on getting back to the canard, so I sanded the canard swoosh tips, the inboard area of the swoosh tips, and the immediate area around each of the outer two hinge tabs with 220 grit paper for about an hour.

I then got pulled away by a few mandatory errands, phone calls and work teleconference.

I ran to Home Depot to pick up some hardware.I grabbed a quick bite while I was out at a nice little Hibachi place, then came back home and got to work on the final sanding of the swoosh tips on the bottom side of the canard.

After about another 30 minutes of sanding, I broke out the primer, mixed it up really well for a good while, and laid down a coat of primer on the bottom side of the swoosh tips, the inboard area of the swoosh tips, the elevator weight pockets and around & on the hinge tabs.

I took quick shot of inboard side of canard swoosh tip area to show what it looks like. Note that I taped up the end of the hinge tab to prime it.

And here the tape is removed and you can see that the majority of the hinge tab is primed.

Next I plan on sanding the primer on the canard, and hitting whatever spots on the canard bottom that need another coat of primer. I’ll then start focusing on finishing the top side of the canard

•••

1 November 2015 — My original plan was to get the bottom of the canard sanded and then West micro finish spread on the top of the canard. However, I ended up spending almost 3 hours sanding down the primer on the swoosh tips, inboard canard tips area, and the two outboard hinge tabs.

Once I fished sanding the first round of primer, I applied a fresh coat of primer on the areas I just sanded.

I then went to dinner and upon returning home I found that the primer in the cup was still flowing out & very wet, so I used it to apply a final coat to build up the total primer thickness as much as possible.

•••

2 November 2015 — Continuing in my quest to get the canard finished, I ended up sanding the bottom of the swoosh tips, the area just inboard of the swoosh tips and the 2 outboard elevator hinge pin areas on each side. Quite amazingly, by the time I was done on the bottom of the canard, 3 hours had flown by.

The corners where the canard end caps (swoosh tips) meet the TE take a while to sand and are time-busting PITAs!

After I got the newly primed areas sanded on the bottom bottom of the canard, I went to work on mounting the canard right-side up to finish the top of the canard. To be clear, my buddy Mike Beasley (AKA “BizMan”) recommended I wait so that I can finish the middle nose fairing on the canard at the same time, but I may utilize an alternative center canard fairing which would negate the standard plans canard nose fairing.

In addition, as I’ve mentioned before (and I have thought about this a fair amount while I’m finishing the canard): As much time as it takes to finish the surfaces of this plane motivates me even more to finish the parts I can in prep for paint so that the finishing of all these parts doesn’t come due all at one time!

I ended up deciding to use 2×3 blocks under the canard to hold it in place while I finish the top. I marked the lower curvature profile of the canard in 5 consecutive spots on a 5′ long 2×3. I used the lower contour profile as a template and after marking the 2×3 I cut out my mounting blocks.

Here are the blocks ready to be hot glued to the work bench.

I ended up only using 4 of the 5 mounting blocks, and I mounted them in the middle of the canard, where the finish doesn’t matter, and at the ends where the swoosh tip junctions meet the canard ends, since these areas will need a decent amount of work on the transition anyways.

I then measured the angle of the table again on each end.

And then matched the surface angle of the canard to the table at each end so that it is aligned, to ensure I’m sanding true while using the contour sanding block.

I then broke out the Bondo and set the canard to the 4 mounting blocks.

Here’s a close up shot of the canard Bondo’d to the mounting block. Note the hot glue holding the block to the work bench.

This is the last time the canard will be in its raw form!

And here’s the top of the canard after I applied the micro finish.

After the West epoxy micro cures for 2-3 hours and is in its “green” stage, I’ll cheese grate the surface to knock off all the high points and get the surface cleaned up.

•••

3 November 2015 — So early in the morning, around 2:30 AM I went down to the work shop to “cheese grate” the micro finish on the canard. Well, the micro hadn’t fully “greened” yet, so it was still a bit gummy. I did what I could for about a half hour, but then gave up and went to bed after setting my alarm for 4 AM to get another half hour of “cheese grating” in. To be honest though, I’ve been exhausted from sanding for hours on end & building the fuselage dolly. Bottom line I slept right through that alarm and missed the “green” state of my micro, so it was nice and cured when I started this afternoon. You can see that the right side is much more cheese grated than the left.

I knocked down the high wave tops of cured micro with the 2″ PVC pipe with 36 grit sandpaper, which is what I used to shape the swoosh tips. After about 10 minutes with the PVC sanding tube, I moved on to the long sanding board with 36 grit mounted on it. Again, I sanded for about 10 minutes with the long board.

Here’s a shot of the left side of the canard after I sanded it with the long board.

After I got the contour somewhat in line, I switched to the contour sanding block with 36 grit sandpaper.

And here’s a couple shots after I did about 3 good passes (~5 minutes) with the contour sanding block.

I then switched back to the long board, using it primarily for the rest of the sanding of the left side top canard surface. Now, I did do a little hand sanding on the top of the swoosh tip and a did a few more quick passes with the contour sanding block. Below is a couple more shots after the major sanding on the left side was complete.

I then started in on the micro finish on the right side of the canard. Since I had done a fair amount of cheese grating on the right side, I started with the long sanding board.

After working the long board for a good 10 minutes, I then switched to contour sanding block. Interestingly, you can see in the pic below that the main contact point for the contour sanding block on the right side was just forward of the TE. Now, I will say that although my canard looks spot on when I sight it by eye, and even run a string on the edges, I think there’s a very slight twist to my canard. Nothing major, but enough to throw some twists (pardon the pun!) into my canard endeavors.

I then checked the top of the canard with the original contour checking template. Now, in the pic below you probably notice a pink LE. Before I took this pic I was checking the top canard profile and kept seeing a gap at my LE, in part caused by my contour sanding block digging into the LE edge a bit. It did get a little of the glass, but not nearly enough to require any glass repair, but I did what something tougher than micro as a foundation so I slathered on a thick layer of Bondo onto the outer 2/3rds of the left side LE.

Since Bondo cures so quickly, after working for a bit on the right side I came back and quickly sanded the Bondo. Now, I know Bondo is heavier, but the resulting sanded layer averages around 30 thou (0.030″) thick. Like I said, it’s enough to give a little depth and a little harder base that can’t get sanded off so quickly. I’m really seeing that both the trailing & leading edges can go uglier fast, so due diligence to these areas is a must.

I then violated one of the laws of the finishing composites by adding a second round of micro to fill in the low points on both sides (left/right, top) of the canard, and also slather a bunch on the LE on both sides to build that up to better get the plans LE shape as close as possible.

Early on I was aggressively shaping the left outboard/bottom swoosh tip when I got to glass, and broke through to the inner layer of glass. With the glass thin at this point, when I mixed up the Bondo, swabbed some on that area too to beef it up just a bit more.

Here’s a couple shots of micro round 2.

•••

4 November 2015 — To start, I cheese grated both LEs & the various spot fills on the canard surface shortly around midnight. I have to say that I notice when sanding micro it seems to be tougher at the beginning when breaking through the shiny layer of epoxy that cures on the surface of the micro. Once into & through that layer, the sanding tends to go a little faster with ever so slightly less pressure (ahem, not implying that a good bit of umph isn’t still required!). Well, cheese grating seems to get to the point where that top shiny surface layer has already been broken through. I’m hoping this is the case and that any difficulties that arise between sanding between micro layer #1 and added micro layer #2 is minimized by cheese grating.

An important realization that I had when I cheese grated the right LE is that the LE still wasn’t thick enough for my (and the contour profile template’s) liking. It was late though & I really didn’t want to be up for another 30-45 minutes, so I left the adding of micro finish layer #3 until this morning, at which point I added more micro to the right side LE. Again, we’re talking if I get 1/16″ added filler depth after sanding (which is always the trick! that damned sanding inexplicably tends to remove the stuff you put on in the first place… bewildering!) then I’ll be happy.

I also noted after checking the canard surface with my contour profile template that the aft side of the left side canard has just a bit of daylight, so I skim coated with micro the entire left side aft canard about an inch forward of the LE in about a 3″ swath. Here, anything that provides a little extra surface depth is golden since I’m not overly concerned about this area. But since I’m contending with other areas on the top of the canard, I might as well take the opportunity to tweak this area as well.

When the new micro was at the green stage I spent a good 20 minutes cheese grating the LE edge area and then I quickly hit the left-side TE swath that I had applied at the same time as the right-side LE.

If you look closely in the pic below, you can see that the swoosh tip has some Bondo on its ridged edge. I applied this shortly after micro layer #3, but forgot to snap a pic of it, which I rectified below.

Here’s a shot of the bondo on the swoosh tip ridge edge. It needs to be built up just a hair to A) cut a near straight line profile-wise from front to back since it has a very slight dip, and B) the ridge needs to be just a tad bit more pronounced (read: higher) to better match the left side ridge.

Again, I know Bondo is MUCH heavier than micro, so I’m using it very sparingly, but I know from experience that it’s some tough stuff. As you can see below, just from the very initial sanding, that I’ve knocked off about 80% of the Bondo that you see above. Once I get the ridge set, I’ll probable follow up the Bondo with a final application of flocro (micro & flox mixed together) to smooth out any irregularities and add to the strength of the ridge.

•••

5 November 2015 — After doing about an hour’s worth of research on some electrical topics I picked up my long board to sand yet once again. (whew! … I’m not gonna get back on my soap box, but I still can’t imagine doing nothing but finishing for MONTHS on end!).

After about 15 minutes of sanding I was very close to the my final contour on the left hand side. On the outboard third of the canard I’m maybe about 30 thou of inch (0.030″) too wide from LE to TE, but the profile is great. And since I was closing in on the LE Bondo layer, and the inboard two-thirds looked really good, I called the left side around 97% good. Any more sanding would have only gummed things up in my opinion, so I stopped while I was ahead.

The right side canard top surface didn’t come out as awesome as the left, but it still looked really good. Since I had to do quite a bit of sanding on the LE area, I tapered it closer back to the shape where I was compelled to add another micro layer.

When I checked the right side with the contour profile template I got 3 near-perfect contours, 2 good contours, and one just ok. Now, again, instead of sanding further and just compounding the problem, I decided to let the 5 coats of epoxy and 2-3 coats of primer take care of any minor surface deviations, and will backfill any major abhorrent surface irregularities that exist in the final finish steps. Taking off a gross amount more of micro finish wouldn’t have done anything but make the overall contour profile even worse.

If I had to call it in percentages of optimum contour, I would give the right side a grade of anywhere between 85% and 89%, at it’s current state. That being said, I’m confident that it will be at a grade of 95-98% of optimum contour by the time I’m finished. Moreover, I’m really happy with how the top canard profile turned out!

I shop vacuumed the work bench and the top of the canard, and then taped up the bottom edges to control any overflow of out-of-control epoxy.

I then mixed up some pure West epoxy and spread it over the canard surface top starting on the right side. It’s amazing how the epoxy wipes removes so many of the sins of micro finishing. I’m not, of course, endorsing sloppy workmanship, but it’s nice to know that the divots, holes from air bubbles and depressions from not enough thickness in the application of micro will be greatly minimized, if not eliminated altogether, from 5 good applications of a very thin layer of epoxy.

Thus, again, Cory Bird is a genius! And I’m glad he made this maddening process a heck of a lot easier . . .

I then finished up on the left side.

After the second application of epoxy to the canard top, I sanded down the first coat of final top coat paint on the headrest GPS antenna puck cover, and then sanded down and added the first coat of final white paint to the elevator outboard weight ice shields.

Now, to be honest I haven’t been blown away with the performance of this boat paint. I don’t have negative feelings towards it either, but the jury is still out. I may need to look at a better way of applying it, because on these parts I just used a cheap paint brush. Thus, we shall see . . .

•••

6 November 2015 — I finished the 4th application of pure epoxy around 2am, and after that I was tapped out. I realize now I need to program in 2-1/2 to 3 hours between epoxy wipes on the surface being finished since 2 hours just isn’t enough. Especially considering that each application of epoxy takes about a full half hour from start to finish to complete.

So, my total epoxy applications at this point is four (4) vs the planned five (5). This actually works out fine because I can tell that I have some areas, the biggest being about 2″ wide, that will need a little bit more fill. In addition, the simple action of repeated sanding –once the primary shape has been locked in with the epoxy finish– refines the surface finish when it finally comes to paint. This may seem like an overly simplistic & obvious statement, but it is true and very evident during the sanding process.

Thus, my “new” (slightly modified) plan was to sand down the current epoxy wipe quite a bit to knock down the high points, level out the surface between the high & low spots, and bring the entire surface of the canard to a much tighter equilibrium finish elevation wise. Then I would add another 2-3 coats of pure epoxy.

I started by checking the surface contour of the canard by not only focusing on the actual contour as compared to the bottom edge of the “F” template, but also by concentrating on the incidence angle that is being conveyed via seeing how the angle of the top straight edge of the “F” template matches the angle of the work bench. In the picture below I have a really good top canard surface contour in addition to a spot-on incidence angle.

I then completed the contour check about every 4-6″ along the top surface of the canard. Below you can see the contour sanding lines I drew on the right-side canard top that denote the high points that need to be knocked down a bit for the canard surface to be better aligned with the contour checking template “F”.

To be clear, by cleaning up the contour profile of the canard (bottom side of “F” template) it had a direct effect of bringing the incidence angle into better alignment (top of “F” template). As it stood, the areas where I marked the lines acted as a high point, or fulcrum if you will, where the contour template teetered upon one way or the other. That being said, it was actually rather apparent that by reducing the middle high point, or “ridge,” that the forward part of the “F” template fell towards the LE and thus brought the incidence angle into proper specs.

Here’s a shot of the canard after about an hour’s worth of sanding with the long board with 80 grit first, then 120 grit.

I then applied 3 more coats of pure epoxy, waiting 2-3 hours between each coat.

Here’s a shot of each side of the canard with the final 3 (additional) coats of epoxy. A few hours after the final coat went on, I spent about 45 minutes pulling the remaining protective tape from the sides and cleaning up the TE, LE, and swoosh tip areas with a razor blade. I got most of the gunk off these areas, but some still remains that will have to be sanded clean once I flip the canard for the final contour of the bottom side, with special focus on the LE.

During one of the ~2 hour curing times between coats I ran out to a auto paint supply store to grab some glazing putty & wet/dry sandpaper to have on hand for this weekend.

I’ll wait a minimum of 24 hours for the epoxy to cure before I do anything to the canard top.

•••

8 November 2015 — I started out today by sanding the pure epoxy coat on the topside of the canard. I began with 120 grit on the long board in a 45° pattern, both to the left and to the right. After I sanded both sides with the long board, I then switched to 220 grit and wet sanded the epoxy finish. This helped get the lower lying areas that should get filled with the high build primer.

Here’s a shot of the right side. For some reason the blog didn’t like the left side pic since I couldn’t load it. Needless to say, it looked about the same.

I then applied primer to the canard. The shot below to the left is the first coat, and the right is the second coat.

In total I added 3 coats of primer. I’ll wait until its cured to block sand it.

Also, as I was prepping the canard for primer I happen to really note the color of the boat paint on the headrest GPS antenna cover and the ice shields. It’s not a bright white, as the primer is not, so I’ll be calling Jamestown Distributors this week to figure out the way ahead on that. I want the white on my bird to be as white as possible… not the 1970’s dull off-white stuff. So I’ll be evaluating the paint further as I move forward.

•••

9 November 2015 — I started off spending a good hour, and 3 good long board sanding sheets, before I finally got the hint that although the primer looks cured, and feels cured to the touch, it’s not cured fully and that’s why my sanding sheets gummed up so quickly. Argh!

So I quickly stopped this futile endeavor and started working on the elevator build prep.

•••

10 November 2015 — After a meeting I had in the office earlier today I ran over to Maryland to pick up a different brand of boat paint. I’m going to do some tests and will report back on the entire plan later on.

I sanded the canard surface starting with 80 grit on the long board, and then switched to 120 grit on the long board as well. I then switched to 150 grit paper and hand sanded each swoosh tip.

I was still getting a fair amount of residue on the sandpaper and had to clean it off the paper at regular intervals. After going through another few sheets of very expensive long board sandpaper (although tonight was much better than last night as far as residue buildup), I decided to wait until tomorrow to finish sanding the top of the canard after it’s cured just a bit more.

In addition, I’m going to hit the canard with another couple coats of primer of the new boat paint. I can tell already that this new primer is much more high build than my current primer, and of course you always need a good base of primer preferably of the same brand. In light of this, I really want to get this primer sanded down to where the canard shape is as close to final as possible, and then smoothed out even more once the new primer is applied.

I then broke out the new paint to try it out. As I said before, as I was looking at the actual color of the white boat paint I had ordered before, in contrast with the white label on the gallon can and a standard white piece of paper, it clearly looked off white. To compare and contrast the new paint I sanded down half of the headrest GPS antenna cover with 220 grit paper, and then painted it with the new paint. I have to say that A) the new boat paint went on much easier and laid down much better than the old boat paint, and B) the new paint seems to have more of a “blue” hue vs a “yellow” hue, as you can see below.

Finally, here are a couple of shots of the canard with nothing but a single light reflecting on its surface. This provides a good view of the imperfections currently on the top surface of the canard. As you can see, there are few minor imperfections –mainly simple & minor surface depressions– on each side of the canard top.

I will also do a final sanding of the current primer on the canard top in prep of laying down a couple coats of the new primer. I’ll then let the new primer cure 24-48 hours before giving it a final sanding.

•••

17 November 2015 — I started by spending about 45 minutes sanding the top of the canard with 120 grit paper using the long board. I’ve got to tell you that sanding it this time around with the primer completely cured was so much easier than the first time around. The primer sanded very nicely and I was able to get a bunch of it off and the canard top very close to its final shape.

At this point I was at a bit of crossroads: I still needed to get the canard flipped to mount the elevators, but I also wanted to finish the surface of the canard top as much as possible. Since I haven’t yet decided on a paint system, and thus the required primer, I couldn’t very well just apply a final coat of primer.

Since there are still surface imperfections & depressions, I decided to fill those before moving forward on any other finish actions. Normally, after a good sanding where so much of the original primer coat has been sanded away, I would simply apply another couple of coats of high build primer and greatly minimize the surface imperfections. But again, since I’m not sure which primer I’m using at this point, I punted and went with filling all the low areas on the canard top surface.

I started by angling a shop light at the surface from each end of the canard and looking at the surface at a very low angle to find all the imperfections. As I found each low point I circled it lightly with a pencil.

I then popped open a can of Z-Grip that a buddy of mine was storing in my shop and said I could use if I ever needed it. I swore that I had used this in past 9 months, but apparently not! I tried stirring this to see if I could revive it, but the ship had sailed on the usability of this stuff.

I had even picked up a tube of hardener for the Z-Grip when I picked up the Evercoat Metal Glaze Finishing Putty, and yes, even though it has “metal” in the title, this stuff is a standard high quality glazing putty and works like a champ on fiberglass applications.

It actually turned out better that the Z-Grip was a pile of goo since for my filling requirements the Metal Glaze worked perfectly. It took 3 separate mixing sessions and about 15 minutes to get the low lying areas filled.

Since the glazing putty cures so quickly, I immediately started cheese grating it to get each spot down close to its final level, using 80 grit strips that I cut out from some used long board sandpaper that I was going to throw away

Here’s a shot of the right side after cheese grating the glazing putty spots.

After returning from dinner, I mounted some peel-n-stick 80 grit paper to my sanding block and sanded just the puttied areas. I got them really close to their final level, feathering the edges of each puttied spot to the existing canard surface.

After the lion’s share of the feathering was completed with the 80 grit hard board, I then loaded up another sheet of 120 grit on the stiff long board and sanded down each side of the canard, focusing of course on ensuring that the puttied areas were blended nicely into the existing canard surface.

I then checked the profile with the top canard contour template on each side, and was very happy with the results.

I cleaned the top of the canard off of any sanding dust, and really took my time feeling the surface with my hands for any imperfections. I then went over the entire canard top surface again lightly with the 120 grit long board focusing on any minor issues left to be dealt with.

I then focused on the edge of the right swoosh tip to feather in the two spots I had filled with glazing putty.

I’m very satisfied with the final fill of the canard top surface. Although I’m sure a few minor elevation differences will rear their ugly heads during future final sandings and surface prep, the top of the canard is ready for a final coat or two of primer, some final wet sanding, and then paint. Obviously, as per above, I just have to figure out what primer & paint that will be!

Next I’ll be focusing primarily on the bottom of the canard: getting all the divots filled and sanding it for final paint prep. I’ll also be remounting the elevators, checking alignment, and rebuilding the left elevator.

•••

18 November 2015 — Today I removed the canard from its mounts and cleaned the leftover Bondo off the mounts.

With the mounts clean (read: no scratching or gouging the top finish), I flipped the canard upside down. I was pleased that the Bondo blobs securing the canard to the mounts turned out to be pretty much in as inconspicuous places as I could possible get them.

If you look closely at the pics below, you can see that the Bondo is right on the line of the junction (or corner) where the bottom of the canard meets the fuselage. Clean up and noticeability in this area shouldn’t be too demanding.

I then took a long shot of the canard –bottom view– that clearly shows that I have a fair amount of work left on the bottom side of the canard as well.

•••

26 January 2016 —

•••

27 January 2016 —I started off today by sanding the internal front edge of the outboard elevator weight pocket to allow the clearance required for the weight to move freely within the pocket.

I then taped up each aft outboard elevator corner to protect it from the glazing putty I would apply to the swoosh tips to level up the TE between both sides.

I was planning on waiting until I applied the high build primer to do any surface patching on the canard, but since I was mixing up some glazing putty anyway, I went ahead and applied it to a number of spots on the bottom side of the canard.

I then spent a good 2 hours sanding the bottom of the canard and finished up with the swoosh TE edges to get them to match the TE of the elevators. The putty on the TE is still a bit rough and will need another round of putty & sanding, but I’m waiting until I do the finishing of the elevators to finalize the swoosh tip TE finishing.

You may note in the pic below that I’ll have to add some micro to the right elevator swoosh tip/elevator intersection gap to even it out when I do the final finishing of the elevators & canard.

I then remounted the canard with attached elevators back onto the upper shop wall.

•••