Before departing . . .

In the air . . .

At RR . . . all parked.

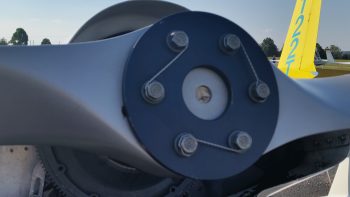

Just a quick note about RR for me. I love talking to all the folks and checking out the birds, but in general when I take pics I’m looking for the details of what different builders have done, either uniquely or just high quality that would be good to emulate. There are a couple of pics of entire airplanes, but even with those I was probably capturing paint scheme ideas!

Checking out rudder lines . . .

Local scenery . . .

Interesting tidbits

Long-Els

Marco giving Mike Beasley a ride!

Jim Voss’s Long-EZ:

……………………………

……………………………

Very customized Long-EZ:

Wheel Pants & Baggage Pods:

Backend stuff:

Cozy nose Oil Heat:

Saturday CSA Meeting

Marco, me & Chrissy Bush off to the right:

Marco, me, Chrissy & Terry Schubert presenting:

Mike Toomey gettin’ out of Dodge!

Me & Marco, back in the air & heading home (via Parkersburg, WV):

Backseat iPad with Foreflight, fed via Stratus ADS-B receiver… works great!

On the ramp at Parkersburg, WV:

Back in the air, heading home to KCPK – Chesapeake:

Starting our decent into Hampton Roads area, just east of Richmond:

Entering the Hampton Roads area:

Coming up on KCPK – Chesapeake:

Back at home base!

MC.