Chapter 13 – “Napster” (NG30) Cover

This page covers the design, development and creation of a simple cap that will cover the rectangular hole at the junction of the large main nose bulkhead (nicknamed “Napster”) and the NG30 front nose gear support uprights.

2 April 2019 — Since I had no real furniture to speak of due to the move, normal places to put stuff got tight…. and sitting on my “end table” (2x4s and plywood) was a scrap of paper that had the dimensions that I had measured up at the hangar for a cap (green thing above) that will enclose the top hole of the NG30s (circled in yellow below).

I know, not a big deal in getting my plane flying, but since I was in 3D printing mode, I figured I would start working up the model to tweak for just a few extra minutes at a whack every time I visited the hangar in NC.

As I was looking for something else, that piece of paper with the dimensions ended up on the floor. Well, in my my attempt (read: frustration) to minimize the clutter, I sat down for 10 minutes and knocked out the CAD drawing for the initial version of that NG30 cap and then 3D printed it…. no need for that piece of paper anymore.

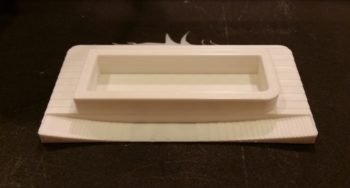

Here’s the blank topside of the NG30 cap.

I do have the initial curved area for the top of the “Napster” bulkhead shaped into the piece, but I’m sure there’s another dozen or so more tweaks that will need to be made before the final version (which will have some type of label most likely), but like I said… with just a few minutes and some notes each hangar visit, I’ll slowly get it dialed in with the correct dimensions and shape.

Here’s another shot of the Napster cover.

•••

19 April 2019 — Today I checked out my one-off design for the NG-30 uprights’ hole cover. I had to trim a bit off the bottom back edge for it to slide into place, which tells me I need to angle that piece.

It fit generally well, but I do have a long list of tweaks that will need to be made for it to fit in a truly acceptable way.

One critical design change that I must make on this hole cover piece is that its height will have to be reduced at least by 0.1″ on the outboard edges. When I tried to place the nose hatch cover back into place with this cover piece in place, there was a slight gap caused by the lack of clearance between the nose hatch door and this cover piece.

Still, I think I’m off to a good start and this will eventually get there design-wise as well!

With my dimensional notes in hand as I head back north, it’s been a fairly productive trip build-wise.

I added this pic below … it’s a pretty good shot of the nose, nose hatch cover and canopy.

•••

29 April 2019 — To get some airplane production rolling [albeit mostly cosmetic], I decided to spend an estimated 45 minutes updating the Fusion 360 CAD file for my NG-30 upright/Napster bulkhead cap, the initial version (green) that I test-mounted in place below during my last trip to the hangar.

I of course planned on there needing to be multiple revisionary updates for this top cap since there a number of angles and a major curve involved.

And not surprisingly, my 45 minutes turned into almost 2 hours . . . oh, well!

Nonetheless, I persevered and was rewarded with a hard fought version 2 of the NG-30 upright/Napster bulkhead top cap.

If you compared the 2 versions, you’d see that I did in fact drop the overall height of this top cap down 0.15″ to provide some required clearance with the nose hatch cover.

I did about 5 other tweaks, including bringing the front corners forward about 0.020″ while leaving the center at the same dimension. This then requires the major upside “U” curve already in place, and then another very minor, shallow curve from the top looking down from each corner aft 0.020″ to the original center plane on the front edge.

I also dropped the back edge down 0.100″ while leaving the front edge the same height. This required an angle on each side… you can see the rough steps –from the draft quality 3D print– of the resulting side angles in the pics above.

•••

5 June 2019 — Today at my hangar in NC I popped in the version #2 of the NG-30 cover that covers the open hole between the NG-30 uprights, the aft bulkhead and the Napster bulkhead.

This latest NG-30 “hole” cover fit much better than the last one and best of all, it doesn’t interfere with the nose hatch closing in place.

•••