Wing Vortilons

Vortilon construction is detailed in the Roncz Canard plans since they are a mandatory addition to the wings if flying the Roncz Canard. There was a well-known Cozy accident that resulted from a main wing stall due in large measure to the pilot/builder removing the Vortilons before a test flight. Clearly these little guys are critical to safety of flight when incorporating a Roncz Canard into the configuration.

Now, as far as classification . . . although these are specified & mandated in the Roncz canard plans (canard = Chapter 10), they clearly go on the main wings (wings = Chapter 19). So I’m adding them here as noteworthy item, albeit I’ll leave this page “chapter-less.”

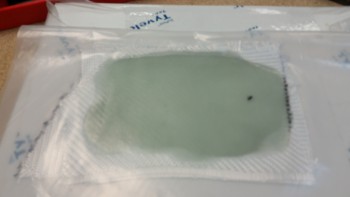

18 October 2015 — Since I had a little bit of pure epoxy left over from glassing the left canard swoosh tip, I grabbed the BID scrap box and a piece of plastic to make a 4-ply BID sheet, of which I would cut out a Vortilon or two. I laid the 4 plies of BID into a pre-preg setup and poured all the epoxy into the layup. After heating up the pre-preg with the heat gun it flowed well enough to wet out all the epoxy. I then put another plate on top of it and weighed it down with my heavy tool bag (pic below).

•••

19 October 2015 — Since I had used some leftover epoxy yesterday to make a set of Vortilons, today I wrote it into the work plan to finish the set for both wings. Here’s the 4-ply BID layup for two more sets of Vortilons.

And here are the initial two that I cut from the glass I laid up yesterday. These are the largest of the 3 sets of Vortilons.

•••