Shop Prep Begins!

13 March 2011 — Once I finished my fuselage mockup, and had checked & ensured that whatever specialized parts there were that I wouldn’t be able build or make would be available to buy, I started prepping the shop for the build. The first order of business was a decent work bench along the wall. I made this one collapsible just in case I needed more space.

Once I got the workbench in place, I started in on the flip-down glass cutting table. The glass cutting table also serves as the glass roll storage cabinet. I think it was the Cozy Girrrls who showed this on their site, along with the thermostat used to turn a light bulb on at a certain temp to keep moisture out of the glass cabinet. I put the flip down portion of the glass table so that it would come down right next to and be even with the sidewall workbench I had just built.

Next, I needed a hotbox to store the epoxy and hardener in when not in use. The warmer the epoxy and hardener is, just about like every other liquid, the runnier it gets and the easier & faster it wets out the fiberglass strands in a layup. BTW, most of the components that I made on this page were made out of scrap lumber I had laying around.

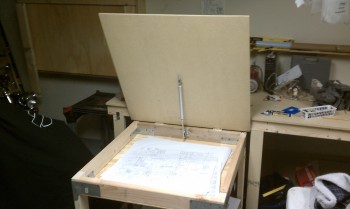

Besides the wall-mounted workbench, I wanted one that was portable and could roll around. So I made this guy below. It had a large enough table top to be used extensively for glassing small to medium sized pieces, and it had storage underneath. Also, I made the top flip up and it was the perfect size for storing the plan’s A-pages (the big drawings) inside the compartment just below the flip up top.

Besides the main 13′ long work bench (spelled out in Chapter 3), this was all there was for building the shop’s major working surfaces.