Chapter 14 – Centersection Spar: Shear Web & Spar Caps

5 September 2012 — I brought the CS spar back out to the work shop and then measured & marked the lines for the spar cap trough depths.

I made the initial cuts for the spar cap troughs & removed the foam.

I marked the Butt Lines (BLs) where I will use 1 of the 4 corresponding spar cap templates.

I then measured & marked out the locations for the aluminum extrusions. The extrusions embedded into–and laid on top of–the foam will line up with both the extrusions glassed into the inside of the spar box and to the extrusions on the wings.

•••

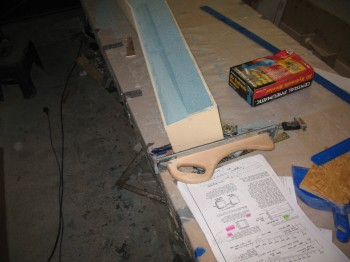

6 September 2012 — I started tonight by making a sanding board jig to sand the spar cap troughs. Before I used the sanding board though, I cut the majority of foam material away with my router.

I set my router at 0.5″ depth & routed the middle 30″ of the top spar cap trough.

I then set the router to 0.4″ depth and routed the remainder of the spar cap channel.

Once I got most of the material out, I used the sanding board jig and other various sanding implements to carefully get the spar cap trough to the depth outlined in the plans.

The plans have you use 4 templates to set on the top of the spar at various points (Butt Lines = “distance from center line of aircraft”). Since the BLs are the same from the center line of the spar, they can be used on each side, and then the depth set at that point to match the template.

From a tip I picked up from David Orr (“Beagle”) and gang, I was fortunate enough to have built my wings before my spar [normally the wings are built later]. Since the end of the spar is nestled into the L-shaped crook of the wing, it makes sense that they should both be the same width . . . lest something (as in a lot of filler micro) must be added to make them match. This of course is not the optimized way to build the wing-to-spar interfaces.

However, having been educated by Beagle, et al, that some builders in the past had dealt with issues of the spar end being significantly thicker than the wing… enough to cause some major work, rework & consternation.

I was able to ensure that the spar end & wing “root” would match by making a template of the wing root at BL 55.5 (the jut out) and match it to the end of the spar. The end of my CS spar was, in fact, slightly thicker than my glassed wing. I taped the BL 55.5 template to each end of the spar and marked the overage with a Sharpie. Later I’ll sand it down to match the wing width, accounting for any glass layup thickness as well.

I then vacuumed up all the blue foam dust and called it a night.

•••

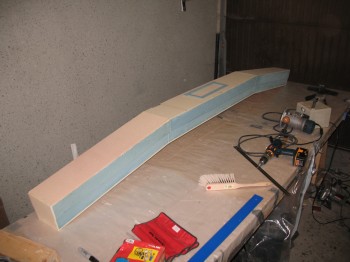

7 September 2012 — I started by routering out the bottom CS spar cap trough. I then hand sanded to final shape using the bottom templates to ensure the depth was correct (just like the top spar cap trough).

I used the Dremel tool to remove the 1/4″ yellow foam on the aft face of the CS spar over the interior (inside the spar box) mounted extrusions.

I cleaned up the newly exposed extrusion faces with Perma-Grit tools & sandpaper.

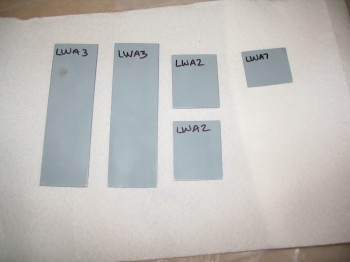

I floxed in 4 each LWA4s (2 each Outboard ends) & 2 each LWA5s (1 each side Inboard). I covered the extrusions with plastic & weighed down.

I then taped all the foam except that which would be covered by the shear web.

Finally, I cut the UNI as per plans (the original plans called for BID, but there was an optional mod to the layup schedule which allowed UNI to be used… saving a number of pounds by using the new UNI layup schedule).

•••

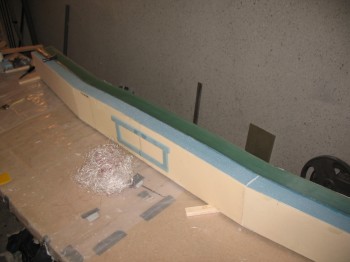

8 September 2012 — I started out today by taping the outline template of the wing BL 55.5 jut out to each end bulkhead of the CS spar. This outline template shows the width of the wing where the wing meets the spar. Since my CS spar is just slightly wider than the wing in certain areas, I’ll narrow the spar down just a tad in those areas before it all gets glassed.

The black triangles in the corner represent the foam that gets removed per plans. The blue marks show the area where the spar is wider than the wing.

[Added] Here’s a pic I found on Nathan Mullins’ Long-EZ build site that shows the build pain that I’m trying to avoid & the steps that you may have to take if the end of the spar doesn’t match the wing (sanding down through the spar glass). You can read Nathan’s description of this process here.

I set up the UNI glass in pre-preg for the shear web.

I micro’d the foam on the CS spar.

I then wet out & laid up the shear web.

After laying up the shear web, I peel plied the glass.

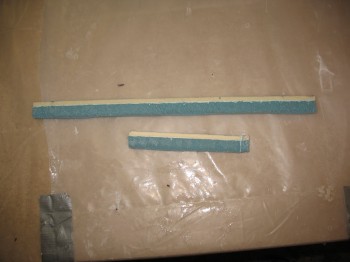

I cleaned & prepped the aluminum extrusions, lined them up & took a pic.

•••

9 September 2012 — I cut & sanded the glass overhanging the edge at the end bulkheads using the Fein saw. I hit the edge with a sanding block & cleaned them up nicely. I then pulled the peel ply off the cured CS spar shear web layup. The layup looked good.

I cut up a bunch of the 1/4″ ply that had been used as the “sled” for the fuselage bottom to use as dams for the bottom spar cap layup. Just like the wing, a dam is required to keep the 3″ UNI tape in place as it’s laid up. Unlike the wing, which only required a dam for a small section of the spar cap channel, the CS spar spar cap sits on the entire aft edge of the spar–one on the top side & one one on the bottom–so it requires a dam the entire full length of the spar.

I then bondo’d & weighed down the dam sections into place.

I cleaned off the table & then grabbed my 3″ UNI tape dispenser. Due the large number of cuts I need to make, I threw my UNI tape onto my table top peel ply dispenser. The CS spar caps take A LOT of 3″ UNI tape, the top a fair bit more than the bottom. It makes sense of course since the spar holds the wings onto the fuselage.

Once the bondo on the dam had cured & I had all the 3″ UNI tape cut, I thoroughly sanded the spar cap trough.

I vacuumed the spar cap trough & all the foam, and then taped up the edges of the foam lying next to the spar cap channel.

In preparation for laying up the spar cap, I measured & marked the BLs for each length of 3″ UNI tape. The bottom spar gets a few full length pieces, and then they start to get successively shorter in pyramid fashion. And just like with the wings, the warning in the Canard Pusher Newsletter mandates to test the cured thickness of the 3″ UNI tape being used, and add plies if it cures too thin. The test I did before I glassed the wings showed my 3″ UNI tape was too thin, so I’ve added a number of lengths of 3″ UNI glass here as spelled out in the plans change.

In wetting out the spar cap channel before glassing, I didn’t like the significant gap that was present along the outside dam edge, due to the radiused corner (although it was only about 1/8″) of the foam when the shear web got glassed. Even though it meant a little more weight, I lined that edge with a flox fillet to keep the layup even & intact, and to ensure the edge would cure strong. I also added some flox along most of the inside foam edge as well since I had it left over.

I spent hours & hours laying up the CS spar bottom spar cap (it was literally over 10 hours from start to finish).

The pics don’t do it justice, and it seems like so much epoxy should NOT be wasted and should be able to be reused. I did actually reuse a ton of epoxy, but it just takes so long to prep, wet out, layup & squeegee one length of 3″ UNI tape, that by the time you get around to even attempting to reuse most of the epoxy, it has already started turning gummy & gloomy (even with a hair dryer… which I fried BTW!)

The pics below give a decent idea of the shear amount of volume of 3″ UNI tape that was used… below is just the pile of roving string & red side strings that get cut in multiple places and then carefully pulled & extracted from the 3″ UNI tape so as not disturb & completely jack up the fibers in the glass tape. The only thing that remains after these are removed is the long fibers of UNI… a good majority of them running 10 feet in length.

Finally, below are some shots of the completed & peel plied lower CS spar cap.

•••

10 September 2012 — Some days are just not good in the airplane building world.

After cutting the ends of the spar cap even with each end of the CS spar & removing the peel ply, I flipped the spar onto its front face to remove the dam that was now not only bondo’d solidly to the CS spar, but epoxied, floxed and glassed as well (even though it’s covered with duct tape… thank God!) .

Well, when I flipped the CS spar onto its front face, I noticed a decent delam along the corner edge of the lower spar cap channel. The glass must have had issues with flowing around the corner from the rear face of the spar to the bottom spar cap channel. The delam was about 14″ long x ~0.5″ average on one side of the center line and about 8″ long with a few areas reaching 0.75″ in width on the other side.

I searched the blogs/Internet & then called Dale Martin to get a crosscheck from a seasoned EZ vet. My initial plan was to cut out the bad glass, recover with 2-plies UNI in the same orientation as called out for the original layup, overlapped onto the existing glass. I would then add a protective 1-ply BID over the entire repair.

I have to say I was feeling much better about it all after talking to Dale, especially when his recommended repair was EXACTLY what I had planned! Not to take anything away from Dale, because he really helped me through this builder’s crisis, but I was just glad that as a newb my decision-making was not too far off kilter. One of the issues that Dale honed in on was the build temps in my shop. The weather in Germany was getting much colder, and the temp swings were often distinct. Guessing on how many heaters to use & when was a constant challenge since even entering & exiting the garage by opening the one big door could keep the Mercury jumping up & down.

MGS is a German epoxy, so it’s good down to around 65° & scoffs in the face of humidity. But my personal minimums–if you will–for building was the normal 70° low end glassing ops temp target. Keeping an un-insulated detached garage, with no central air, heated during the German winter to say, 80-90° F constant, was cost prohibitive and simply wasn’t going to happen. My only other option was to stop building, which was going to happen in mid-October regardless, since I was deploying to Tampa for 6 months (the irony of having such a great Winter building location as Florida, with your entire project located in Germany!)

So I did some more research & then developed my plan of attack. I then cut out & removed the delam’d glass.

To get back on track & get back into a positive build groove, I cut the 3″ UNI tape for the lower spar cap.

I then went to the cutting table in my downstairs shop & cut the 2-plies of UNI and 1-ply of BID for the repair.

I refilled the hardener bottles & poured the last of the MGS from the large plastic container into a gallon jug.

I then went back to work removing some of the bigger chunks of the 1/4″ plywood dams. The thin ply wood worked well as a dam, but it was playing hell getting it off the CS spar because it would simple splinter & shatter when I tried to remove it since it just didn’t have the strength to stay together.

•••

11 September 2012 — Today I started by sanding a good majority of the plywood dam remnants off the CS spar during my lunch break. Later on, I sanded a bunch more (the 1/4″ plywood was simply a PITA to remove).

I prepped the foam near the corner of the shear web on the edge of the lower spar cap channel where I would be laying up my repair glass. I used a mixture of flox & micro on the newly bared foam. In a few spots I used straight flox for a smooth transition from foam to the existing glass.

I prep-pregged & laid up the 2-ply UNI & 1-ply BID on the lower spar cap channel. I then peel plied the newly laid repair glass.

As for pics, you are probably noticing a trend. As I transcribe my build log from my notes & put them online, I notice that documenting events tended to go by the wayside when I went into crisis/repair mode. Thus, unfortunately, I don’t have any pics of this repair. I would say that I will try to do better in the future, but my days of making any mistakes during this project are behind me, so I won’t have any to document. HA! (I wish . . .)

•••

12 September 2012 — Today I removed the peel ply from the CS spar bottom spar cap trough repair layup… it looked good.

I sanded down the spar cap trough & cleaned up the peel ply goobers.

I then used 1x2s for the lower spar cap Outboard dams, and because I’m cheap (and slightly retarded) I reused a recycled piece of 1/4″ ply from the top spar cap layup for the center dam piece. I bondo’d the dam pieces to the CS spar for the lower spar cap layup.

I did a final sanding & cleanup of the lower spar cap trough & vacuumed the entire layup area. I taped the foam adjacent & lying next to the spar cap trough & then marked the BLs for the individual lengths of 3″ UNI tape that would be glassed into the spar cap.

I mounted the epoxy runoffs on each of the spar and repositioned the spar lower & secured it in place. I needed it lower because hours & hours of glassing these spar caps will give you carpel tunnel & make your hands numb from the odd position they’re in while glassing.

I floxed the front of the channel again just like I did on the upper spar cap, before laying in the 3″ UNI tape. I then glassed the lower spar cap. I started around 8:30 pm & finished at half past Midnight (4 hours).

I peel plied the spar cap and called it a night. Below is the total amount of epoxy I have left from the huge container I bought in May. So far, I’ve used about 8 gals of epoxy since I’ve been in Germany.

•••

13 September 2012 — I checked the lower spar cap layup first thing… it looked good!

I pulled the peel ply & Fein-sawed the ends off level with each end bulkhead.

I then removed the dams & chiseled off the residue. I sanded the aft face of the CS spar to remove the dead bondo, epoxy, etc.

I then belt sanded the upper spar cap to level out the “steps.” The steps are the end of each subsequent layer of 3″ UNI glass after it cures. The stuff is so thick that even though it gets peel plied, there is a very visible step at each layer of glass in the spar. The belt sander helps smooth it out so that it’s not TOO lumpy when the spar gets it’s final wrapped glass skin.

A builder’s tip on laying up spar caps I received AFTER I glassed 6 of the 8 spar caps on this bird (the last 2 are on the canard) is to pull the individual strands in each layer of 3″ UNI tape so the are very staggered on each end. You still have the same amount of glass, it’s just spread out over a broader area…. so doing it the easy & efficient way is fine for some builders, but I’ll stick to my knuckle-dragging Neanderthal ways thank you very much….ha! (sheesh . . . )

I also sanded down the foam adjacent to the spar cap to make sure it was level & smooth.

Below are some good shots of the wing-to-spar bolt extrusions & the CS spar caps.

•••