Chapter 13 – Nose & Nose Gear

[Check out Nose Gear Wiring page under Electrical System]

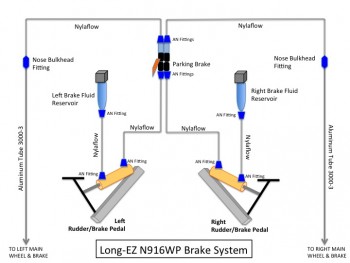

22 December 2012 — Rudder & Brake Pedals

The Rudder Pedals are covered in Chapter 13 of the plans, Nose & Nose Gear. The Master Brake Reservoirs were covered in the chapter on the firewall (Chapter 15) because that’s where they were originally located.

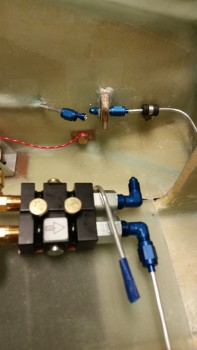

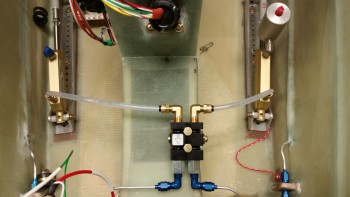

Many early builders, including Debbie Iwatate, moved the master brake cylinders off the firewall, putting them up front either on or near the rudder pedals. Dale Martin perfected this design and sells it in a nice package as shown in the pic below. It’s a bit expensive, and I probably could have made them myself, but time is money to me and these are nice. Plus, Dale includes specific instructions on how to install these guys so as not to bungle anything up! One really nice feature on these, besides getting your brake cylinders (and thus weight) off the firewall, is that they are adjustable, so you could move them farther or closer to pilots of various heights.

•••

14 May 2013 — Now, onto the real subject of this post: the Front Gear Strut. Chapter 13 of the Long-EZ construction plans covers the Nose & Nose Gear. I will of course be deviating from the plans in large measure since I will be installing Jack Wilhelmson’s EZ-Noselift electric nose gear actuator in lieu of the old mechanical system. In addition, I will be constructing a longer nose using the Davenport design, which will change NG-30 gear housing/nose assembly and the forward bulkheads. In doing so, much like the elevators & canard where I was using 3 sets of plans: Long-EZ, Roncz Canard, & Cozy Girrrls; for the nose I will also be using three sets of plans: Long-EZ, Wilhelmson’s nose lift, & Davenport nose design.

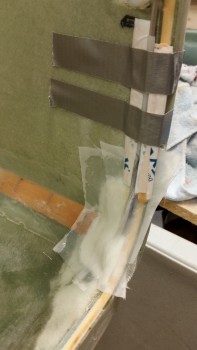

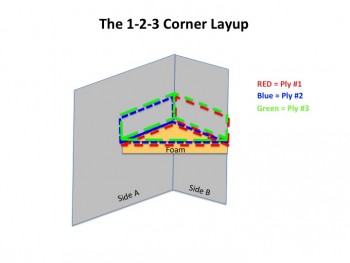

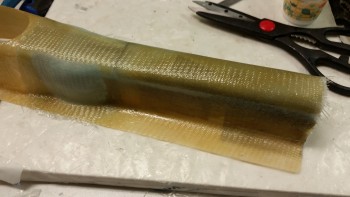

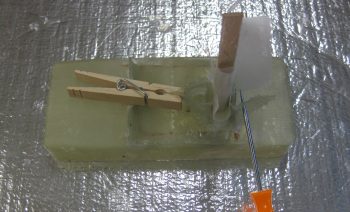

Step 1 of Chapter 13 is to add 2 plies of BID to the nose gear strut for reinforcement, in the same fashion as is done for the main gear with all its extra glass plies. The BID plies on the nose gear strut are simply 3-sided layups in opposing directions (shaped like this: Π ) with the second ply overlapping the sides of the first ply.

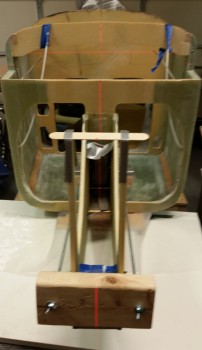

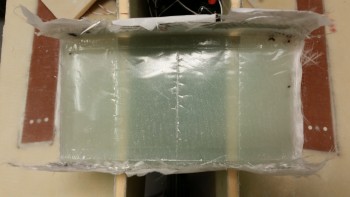

To start, I screwed down a scrap piece of wood to the workbench as a mounting board.

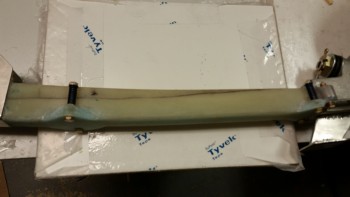

I sanded & then 5-min glued the NG-1 nose gear strut (made of solid S-glass, just like the main gear) to the mounting board, with the aft side of the strut facing up.

I then glassed the first 1-ply BID layup onto the NG-1 nose gear on the Aft, Left & Right sides using fast hardener, since it was a fairly small layup.

Of course I then peel plied the entire layup.

•••

14 May 2013 — I started today by pulling the peel ply & knife cutting the nose gear strut. I then sanded the edges of the new glass layup.

I remounted the NG-1 nose gear strut to the support mount using bondo and with the forward side facing up.

I then glassed the second and last 1-ply BID layup to the Fwd, Right & Left sides of the Nose Gear Strut NG-1, again using fast hardener for the epoxy.

Then I peel plied the layup. This side was much more difficult to get the peel ply to grab then the first side, but I eventually got it all in place.

•••

16 May 2013 — No pictures tonight. Just a quick update on the NG-1 Nose Gear Strut.

I knocked the nose gear strut off its work table mount, sanded it & cleaned all the bondo off of it. Chapter 13 Step 1 for the NG-1 nose gear is complete.

•••

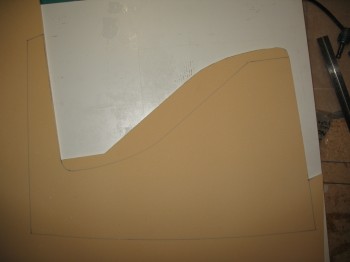

19 May 2013 — Today I decided to act on yesterday’s vow to figure out my build plan for the Davenport extended nose. I broke out the Davenport extended nose plans, figured out a myriad of details and made a template for my NG-30s.

One thing in specific I was looking at was the battery position & its installation configuration in relation to the heated pitot tube, and how it effected the capability of retracting the pitot tube.

Now, let me backtrack to February 2013. I may have been a little remiss in the reporting of my project progress since I overlooked an extremely important component: my retractable heated pitot tube made for me by my good friend Marco, a fellow Canardian and Long-EZ builder . . .

Yes, Marco–being the excellent & talented machinist that he is–machined me this beautiful retractable heated pitot tube. Of course this wasn’t just a simple ‘throw some metal on the lathe and here it is’ endeavor, it took literally a couple months of research and discussion, and quite a bit of engineering and design. And countless hours of machining work by Marco. Marco describes the first part of the process here on his Blog What have I gotten myself into!

In addition, Marco covers the features of my Pitot Tube in this awesome video he made:

•••

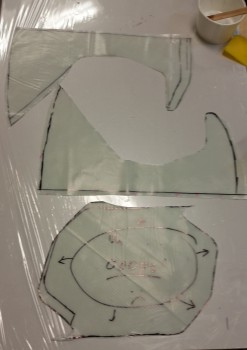

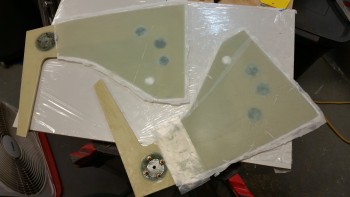

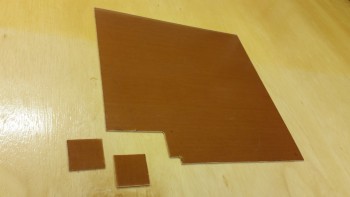

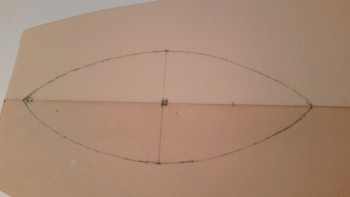

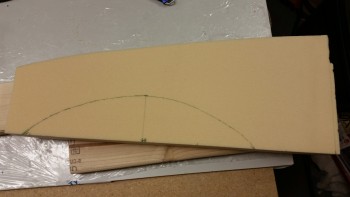

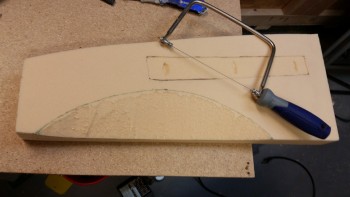

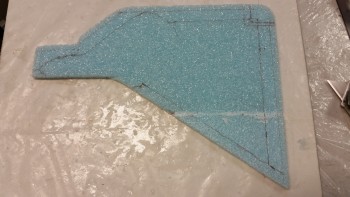

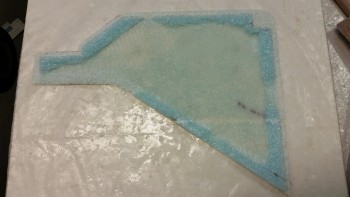

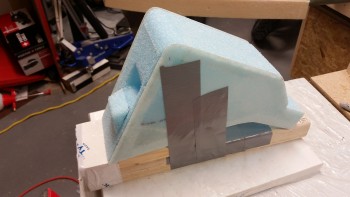

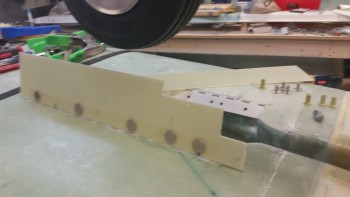

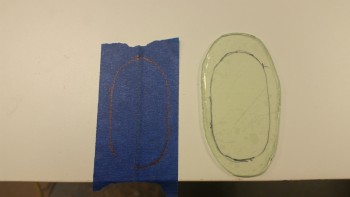

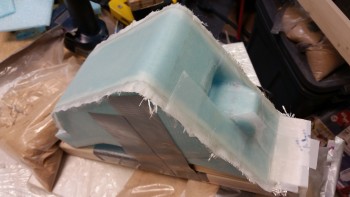

20 May 2013 — Today I cut out the NG30 high density foam plates that make up each side of the channel that the nose gear electric actuator will sit in. Not only do these plates start out with some of the densest foam out there (the H250 has a 16# density), but it gets covered with a 4-ply BID layup on each side of just ONE plate, so that’s 16 plies between the 2 plates. Also, in talking to Jack Wilhelmson about installing his landing gear actuator, I added 1 ply of reinforcement BID along the top curved portion of each NG30 as he recommended just to add a little robustness & strength

[Note: Like many other components I’m building on this Long-EZ these NG30s are not to built to stock specs as spelled out in the plans but rather they follow the Davenport extended nose design, which obviously look different than stock plans NG30s].

I trimmed down the sides & sanded them even so that the NG30s closely matched each other.

•••

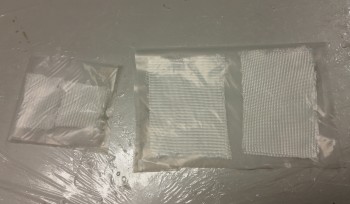

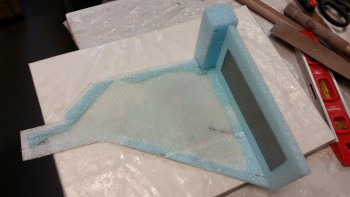

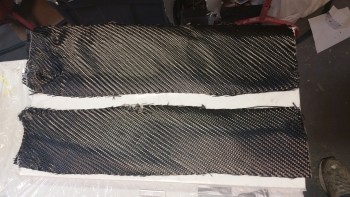

21 May 2013 — I started off by using the NG30 template to cut 8 pieces of BID @ 90° & 8 pieces of BID @ 45° so the glass would have alternating bias when I glass the sides (4 plies each side).

I glassed the alternating 4-ply BID layups on the Inboard sides of the NG30 foam plates & then peel plied them, starting with the Left-side NG30 high density foam plate.

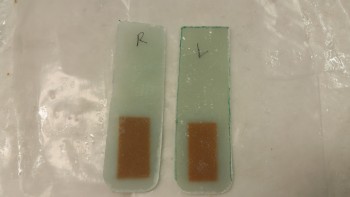

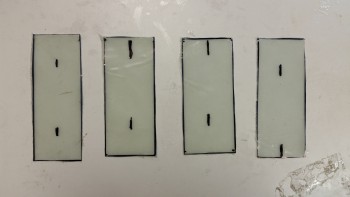

Below shows the two completed glassed & peel plied NG30 sides.

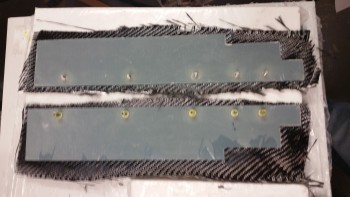

Here are the finished Inboard sides of the Left & Right NG30 plates.

•••

22 May 2013 — I knife cut the edges of the NG30 plates & pulled the peel ply.

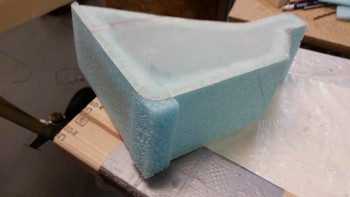

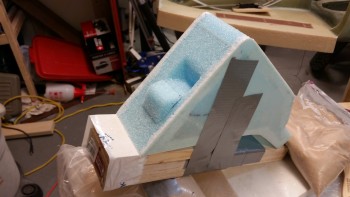

I call the 2 pics below the “F-117 Canard” pics . . .

I also stacked the NG30 plates just to make sure I had as near-perfect alignment & symmetry between the two as possible.

•••

23 May 2013 — I spent a lot of time at my planning table in the house tonight to figure out my nose & nose gear configuration. I was about ready to ask my buddy Marco if he could machine some NG14 spacers (they sit in between the NG30 sides), but then I found them in the EZnoselift kit that Jack Wilhelmson sent me. And here they are:

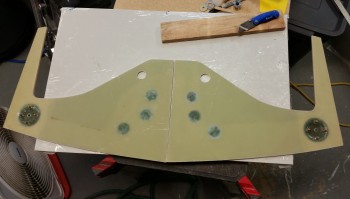

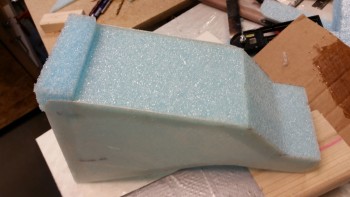

I then planned out and designed the first & larger of 2 bulkheads that I’ll be building for the Davenport extended nose. I did modify it just a bit, because my front nose hatch will be larger than the stock Davenport hatch, traversing the large bulkhead (thus the indentation at the top). Since I was running low on H250 high density foam, and since it’s extremely expensive (for you non-Canardians, it runs about $105 for a 2 ft x 2 ft sheet … yes, it’s that tough as far as foam goes. And tough to cut too!) I used 2 pieces to make up the larger nose bulkhead (this, incidentally, will mount on the front vertical arms of the NG30 plates).

Of course as soon as I got the foam cut out & the bulkhead pieces together, this part quickly was dubbed with the moniker “Napster”.

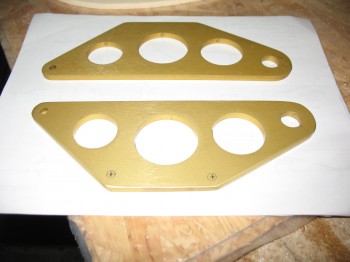

Finally, I measured out the nose lift brackets & correlated them with the NG30 holes. This had to be done before I continued on glassing the NG30 plates, since the next step is to glass in the hardpoints that will secure & be mounted to these nose lift actuator brackets below.

•••

24 May 2013 — I started today by double-checking the hard point positions using Jack Wilhelmson’s EZnoselift actuator as a guide.

Before I used the paper NG30 template to mark the hardpoint centers, I sanded the NG30 plates’ edges to match.

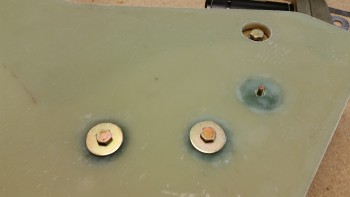

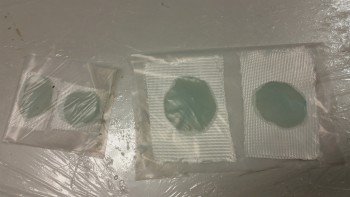

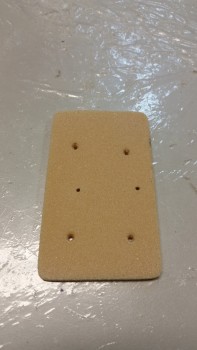

I then focused on cutting 2 each NG8 aluminum disks out of a 0.125 in. (1/8″) 2024-T3 plate. These discs will reinforce the glass hardpoints and will help carry the loads of the pivot bolt that the NG6B Nose Gear Pivot Casting (and the front gear strut) pivots around.

Per plans, the NG8s are supposed to be 2.8 inches in diameter. Considering I’m using a electric hand drill with German metric hole bits, I’ll take my 2.754″ inches diameter and be happy about it.

And because I have an incredible sense of humor (yuk, yuk . . . see?!) I had to use these NG8s for Napster’s eyes before I drilled the 4 smaller screw holes:

And then here’s a serious shot with the 4 smaller #12 screw holes drilled in the NG8s.

In addition, I drilled a number of circular wooden plates that I covered with tape to use in weighing down the glass in the circular hardpoints.

I then located some scrap BID & set up my pre-preg layups for the hardpoints (shown below).

I used my NG30 paper template to transfer the hardpoint centers to my NG30 plates.

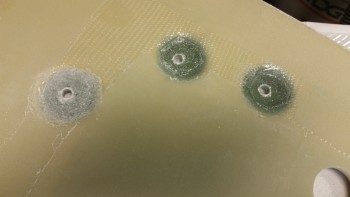

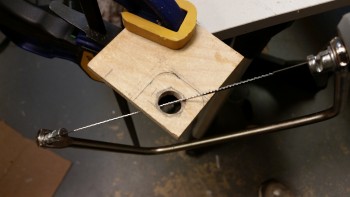

I then drilled the marked holes to lock in & ID the center positions of the hardpoints.

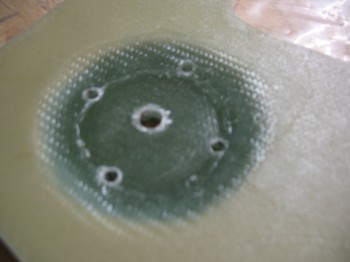

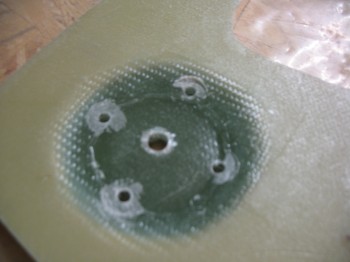

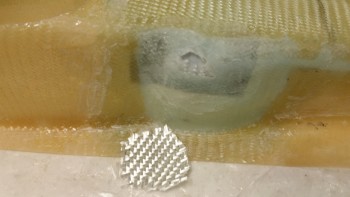

I then marked the outlines of the hardpoints, and starting with the Left NG30 plate, removed the foam down to the inside of the Inboard 4-ply glass. I sanded & prepped the “bottom” of the hardpoint positions for the 15-plies of hardpoint BID that would get laid up into each hardpoint position hole.

I put the paper template back over the NG30 to confirm the correct positioning of the hardpoints. I also set the NG8s (below right) to get an idea how they would look when positioned.

I wet out the BID in the pre-preg setups & then cut the circles out for the hardpoints. There’s 3-plies of BID in the pre-preg setup, so stacked it will make the total number of BID plies required for all the hard points.

Since the 15 plies came out thinner than I expected, I threw an extra 3-plies into each hardpoint ‘hole’ for a total of 18 plies per hardpoint. Before the hardpoint BID layups were glassed at each point, I had whipped up some flox & spread it around the foam edges to fill in any gaps and irregularities. I then glassed the NG30 Outboard side just as I had the original Inboard side, with 4 plies of BID at alternating biases: 2 plies at 45° & 2 plies at 90°. I also added an extra strip of reinforcement BID (as per Jack’s suggestion) just aft of the front hardpoint and focused on the upper curved section of the NG30… it ends above & just forward of the aft 3 hardpoints.

Once I glassed the 4-ply BID layup on the Left Outboard NG30 plate, I peel plied it & weighed down the hard points for a nice tight strong layup at each hardpoint.

I didn’t like my initial hardpoint weight schema since I didn’t have good eyes-on with the glass surround the hardpoints, so I switched it up to that shown below.

I also micro’d the Napster (large bulkhead) halves together and then glassed a 2-ply BID layup & peel plied it.

•••

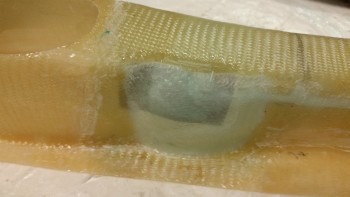

25 May 2013 — I started today on the Left NG30 plate. I knife cut the edges & pulled the weight plugs from the hardpoints.

I was trying to find that point in time that is the “sweet spot” for pulling peel ply . . . when it comes of easy & doesn’t leave any peel ply boogers and still leaves the surface nicely textured. However, I have to admit I was a bit hasty in finding the sweet spot, so that’s why the surface of the Left NG30 plate above is a bit shiny vs. the usual dull after a glass surface has been peel plied.

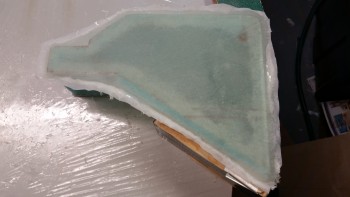

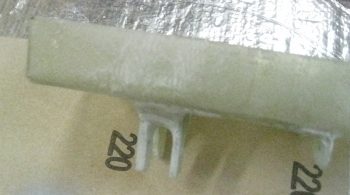

The pic below shows the edge of the NG30, with 4 plies of glass, the H250 high density foam, and then another 4 plies of glass.

Since it took a fair amount of time & a lot of elbow grease on the Left NG30 plate to dig out the foam at the hardpoints, I decided to change up my technique. This time on the Right NG30 plate I used a Forstner bit. I had to be careful, but it worked wonders and cut the time to get the hardpoint holes configured correctly in less than 20% of the time as it did on the Left NG30 when doing it with the Dremel & by hand.

Below is the finished aft 3 hardpoint positions for the Right NG30 plate after the hardpoint divots had been cleaned up, with the following pic showing all the hardpoint positions.

Before I glassed the Right NG30 plate I grabbed Napster . . . and pulled the peel ply.

And because I was low on H250 foam, I used 1/4″ thick Birch plywood for the very front nose bulkhead. I marked the outline on the sheet of ply, and then cut it out.

I now had side A of the front Birch plywood nose bulkhead and side B of Napster ready to glass.

I started with the Right NG30 plate by pre-pregging & glassing the 18-ply hardpoint layups, after lining the edges of the hardpoint holes with flox.

I then laid up 4 plies of BID across the entire Outboard surface of the Right NG30 plate. Also, just as on the Left side, I glassed a 1-ply BID reinforcement across the top edge for added strength. I then peel plied the layup & weighed down the hardpoints.

After I got the NG30 situated, I glassed a 2-ply BID layup on side A of the smaller wood nose bulkhead & a 2-ply BID layup on side B of Napster. I peel plied both of these layups as well.

•••

26 May 2013 — I pulled the peel ply off the Right-side NG30 plate, Napster bulkhead & the forward nose bulkhead.

I drilled 4 #12 holes for (not in) each NG8 aluminum mount–using the NG8 as a template–through the NG6 glass hardpoint in the NG30. I also drilled the 5/16″ center hole in the hardpoint for the NG6B front gear pivot mount.

At the back end of NG30 I drilled a 1/4″ hole through the lower hardpoint for the EZ Noselift actuator mount.

I then mocked all this up as shown below.

As for the 2 nose bulkheads, I had to put Napster (the larger one) into timeout because he was warped! I weighed him down & put the heat on him to straighten him out.

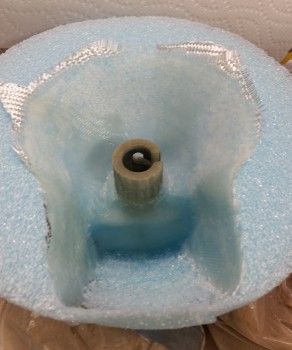

I had laid up a 2-ply BID layup using fast hardener on side B of the front nose bulkhead (smaller one) & then peel plied it. A couple hours later I pulled the peel ply off, sanded the edges, and then drilled a hole in the center of it that will eventually allow the retractable heated pitot tube to retract into the nose.

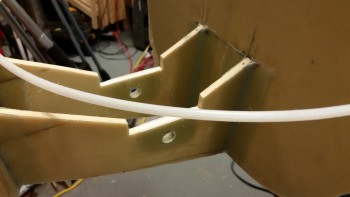

Next I went into high density foam cutting mode. With the Davenport nose there are 2 additional arms (BC1)–extensions of the NG30 assembly if you will–that lie in between the smaller nose bulkhead (pictured immediately above) and the larger bulkhead we affectionally refer to as Napster, in the Battery Compartment area. So in addition, these BC1 extension arms are notched to hold the Odyssey PC680 battery in place. I cut the 2 BC1 pieces out of H250 high density foam.

I also cut 8 pieces of “scrap” BID for a 2-ply layup that will be glassed on each side of the BC1 battery compartment plates/NG30 extensions. I then glassed side A of these BC1’s (no pic) each with a 2-ply BID layup & peel plied.

Finally, I cut the F4.1 piece that will get glassed on the AFT side of the upright NG30 arms (the front side of the NG30 arms will get glassed to the aft side of Napster).

•••

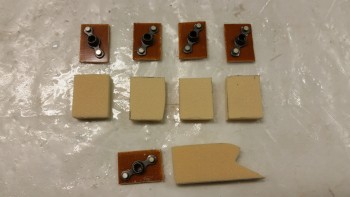

27 May 2013 — I removed the peel ply from the BC1 Battery Compartment struts (NG30 Extensions) & then knife edged and sanded the edges.

I then glassed side B of each BC1 with a 2-ply BID layup & peel plied.

Here is the end result a few hours later after the BC1’s cured (I used fast hardener since the layups were small). I pulled the peel ply & trimmed the edges.

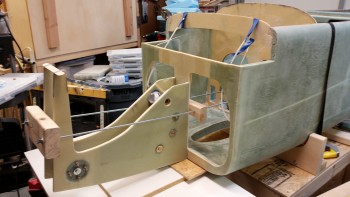

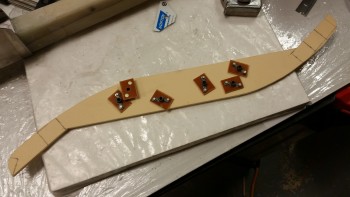

I mocked up all the NG30 pieces–except for Napster, who was still in Time Out under the heater–to get an idea of how it all looked put together. Again, except for Napster, which gets mounted on the front of the NG30 vertical arms & aft of the BC1s, this below is the skeletal framework for the nose.

•••

29 May 2013 — I didn’t do much today on the project either, but I did get my countersink in from Aircraft Spruce & immediately put it to work.

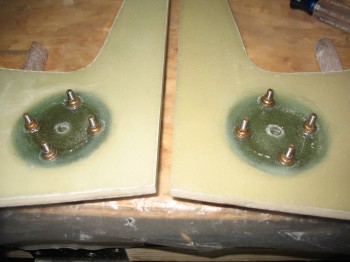

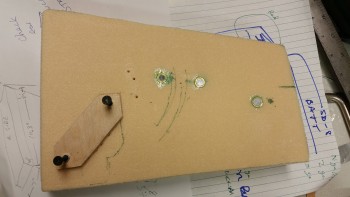

I countersunk the 8 each #12 screw holes in the NG8 aluminum plates.

I then tried them out by mounting them to the NG30 plates.

•••

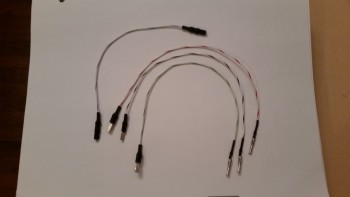

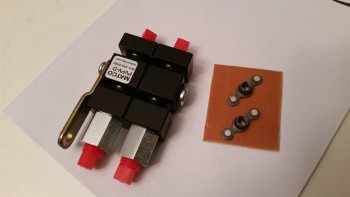

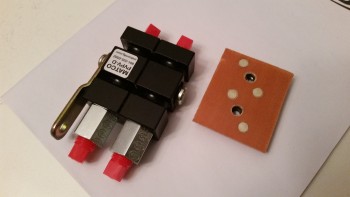

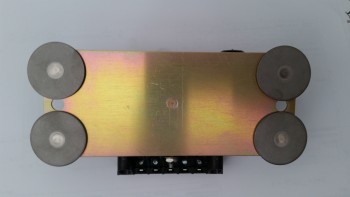

5 June 2013 — Today I received the NG6B from Jack Wilhelmson. The NG6B is a “special modified NG6A with threaded internal bearing spacers with two AN5-15A bolts. For use when the AN5-41A bolt cannot be removed without cutting or drilling holes in the fuselage.” (The spring in the pic below left is the spring that goes between the rudder cable & the rudder/brake pedals–one on each side. I had the springs on hand, so I made this up. There are some ways to configure the rudder/brake system so it doesn’t require this spring which I’ll research out more . . . but just in case!)

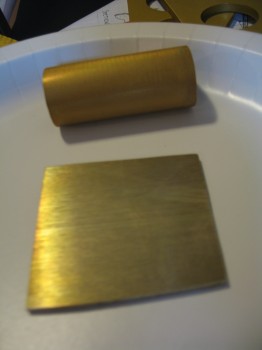

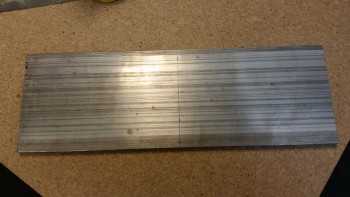

Now that my NG6B is here I can cut my 1/8″ thick 2024 aluminum stock to make the NG5, which is simple the plate opposite the NG6B that sandwiches the Nose Gear Strut & gives the screws a strong surface to compress against, like a clamp around the strut vs using only the fiberglass of the gear strut.

And here’s how the pieces look together. Of course when mounted there are 4 screw holes in the NG5 plate & the nose gear strut sandwiched in between the NG6B & NG5.

•••

6 June 2013 — Today I started off by Alodining 2 each NG8 brackets & NG14 spacers from Chapter 13 and the pitch trim actuator bracket I just made for Chapter 17. I used wire held down by my mini sandbags to hang the smaller parts on to dry.

•••

11 June 2013 — Today was a light build day. I Alodined the nose gear strut attach plate (NG5).

•••

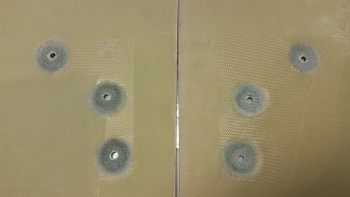

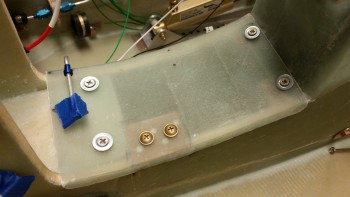

15 June 2013 — I started out by prepping the NG30 plates for attaching the NG8 aluminum plates.

I shaped the 4 small screw holes on the Outboard sides of the NG30 plates with the Dremel tool so that each nut & washer would be on a flat base.

Under the watchful eyes of my Quality Inspector (aka “Big Brother”) I used a thin film of flox on the NG8s to attach them to the Inboard sides of NG30 plates & used thick flox paste under the Outboard washer/nut assemblies to ensure that there was a flat base for the nut/washer assemblies when the flox cured.

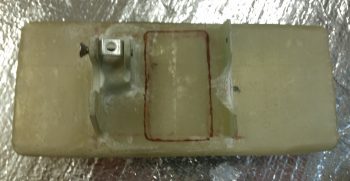

Below are the NG30 plates complete with the NG8 plates screwed on in place.

Once I had mocked the NG30 plates up & performed a sanity check on the Chapter 13 nose components, I cleaned all the nose & nose gear related parts & took them down to the basement to await packing, shipping & storage.

•••

26 October 2015 — On with the nose gear!

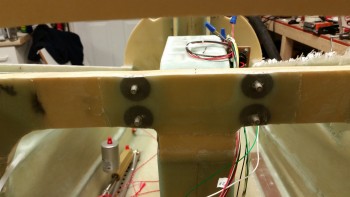

I measured everything out with the sidewall brackets that sit internal to the NG30 plates and hold up the electric gear actuator.

Unfortunately my zeal got the best of me. After checking something in the gear actuator install instructions I ran across a statement where the holes in the brackets (not shown) need to be 3/8″ away from the side of the bracket at the center of each hole. Mine were set at a 1/4″ away from edge to hole’s center. This changed the angle required to get the holes drilled correctly for the brackets. Not a huge a deal, I’ll just have to widen that top hole a bit aft.

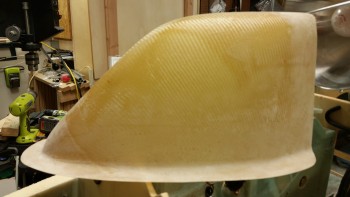

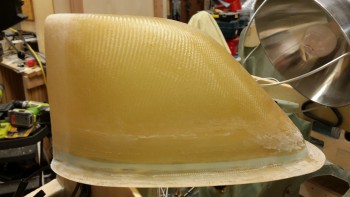

Oh, and speaking of NG30’s and stuff, look what just came in the mail: my nose! Says on the box that some assembly is required! Haha!

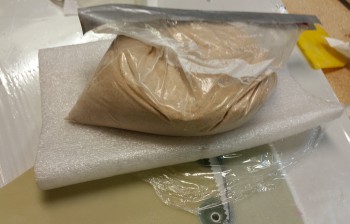

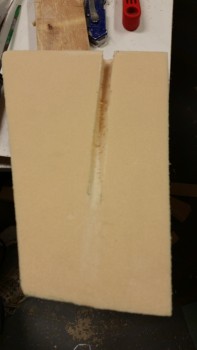

Interestingly, I was just having a conversation the other day with a good builder buddy of mine talking about how some builders have yellow foam in their build that isn’t polyurethane, but actually Divinycell (H45). Well, guess what? My “blue” Divinycell foam showed up yellow. I mean, I asked ACS if they could send me the lightest Divinycell possible . . . but I was talking WEIGHT, not COLOR! ha!

•••

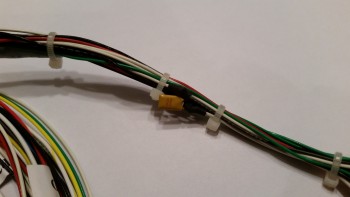

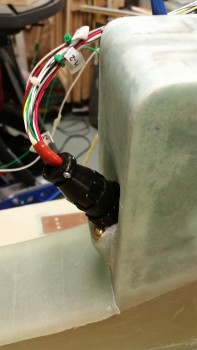

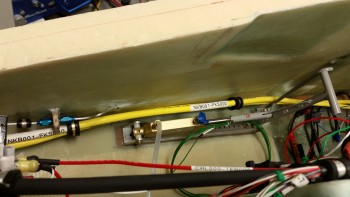

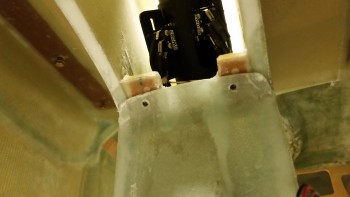

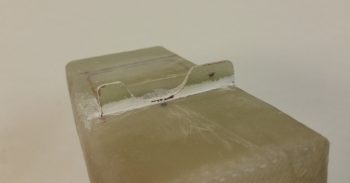

27 October 2015 — I sat down to fix a design flaw in the Nose Gear Actuator wiring before it became a problem. There is a small electrical component (diode? capacitor?) that was soldered in the wiring line with one of its two tiny legs soldered to a wire on each side. If you look at the second pic you can see daylight between the component and the wiring bundle.

Now, my Long-EZ building buddy Marco (AKA “Capt Meatballs”) pointed this out to me after his broke and he had to find it via troubleshooting. The connection legs were so fine, that when the one side broke he had to buy an entire new component & solder back into place to fix it.

To avoid this issue I employed the “poor man’s electrical potting material” solution to this situation. I took electrical tape that I had folded over a couple of times and wedged it underneath the suspended wire legs on each side to secure them from any pressure coming through the tape and still snapping off one or both of the legs. I then wrapped the whole assembly in electrical tape. May not be the prettiest fix, but with a big clump of relays just down the line I wasn’t able to get some tubing shrink wrap over it. So this fix will have to suffice!

Now that I have the base of the fuselage dolly built, I’ll start incorporating it into the build schedule. Thus, while any part, epoxy, or primer is curing I’ll take a few moments to get this dolly built. My plan is that when I start in seriously on the nose & nose gear that I’ll have this fuselage dolly underneath the fuselage and ready to go.

•••

28 October 2015 — I grabbed a battery tender from the garage & put the small emergency back-up battery for the nose gear on a trickle charge to get it ready to go when I eventually wire up the nose gear to test it out.

•••

29 October 2015 — I started off this morning working for about an hour on some build project housecleaning duties such as updating my spreadsheet with recent purchases, and my project “Order of Battle,” and my specific to-do lists for each chapter.

After getting the paperwork out of the way, my first priority of the day was to work on all the stuff that makes noise. If noise wasn’t an issue, I would have worked on the canard first, then the nose NG30’s, and then the fuselage dolly. But, since I can’t be making enemies of all my neighbors, or keeping the neighborhood awake with my plane-building shenanigans, then I need to prioritize to get my clanging & banging finished ASAP in the day.

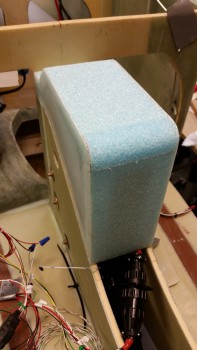

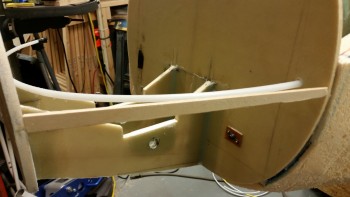

I started off today working on the NG30’s for the nose. I needed to get some minor stuff taken care of so I could glass the aft inboard side with a 2-ply BID layup. This layup would serve 2 purposes: 1) It covers the depression made in the upper aft area of each NG30 to allow freedom of movement of the nose gear actuator housing, and 2) It reinforces the aft inboard edge of each NG30 with 2 plies of BID to strengthen the NG30 when attached to the center post of F22. This was a recommendation I received from Jack Wilhelmson back in 2012, so I of course complied!

The first of this required stuff was to drill the 1/4″ holes for the actuator mounting brackets in the right NG30, by using the left NG30 as a template to make sure the holes are perfectly aligned. Once the NG30’s were aligned and clamped it took very little time to drill the holes.

The next order of business was to expand the NG30 upper holes that provide clearance to the main nose gear actuator connect bolts. This expansion is a result of the boo-boo that I mentioned earlier where I overlooked Jack’s mandate that the holes on the edge of the actuator mounting brackets are required to have 3/8″ clearance from the edge of each bracket to the bolt hole. I’m fairly certain I was using the original holes shown in the old plans NG51s (mount for mechanical nose gear retract assembly) for reference, and those didn’t have the proper clearance. The bottom line is that since I had to move the holes on the mounting bracket further away from the edge, it caused an issue of bolt clearance in the very top open hole. It needed about 0.15″ more space at the aft end of the hole.

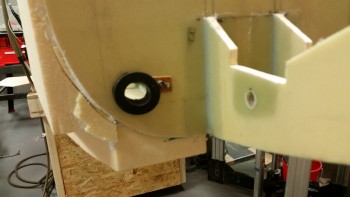

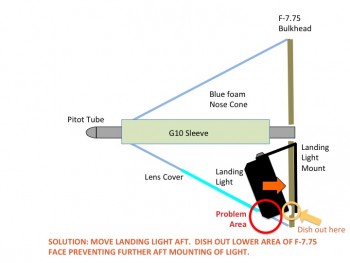

As I was checking the spacing on the upper NG30 hole below with the actuator installed (see pic below), I also marked off the area of the upper NG30 that needed to be removed to allow the proper clearance of the nose gear actuator top motor housing (the anodized gold cap at the bottom of the actuator in pic below).

Here I’ve prepped the Dremel tool to use on expanding the upper holes. The area marked at the bottom of the hole is the offending mass that must be removed!

The last task on my list before glassing the inboard NG30’s was to remove the area that I had marked off above to allow unhindered movement of the nose gear actuator.

I used my router with a 3/8″ “square” bit and freehanded the cutting into the NG30 tops. I set the depth at just a hair over 0.2″ (say, 0.21″)

After using the straight bit, I used a “V” bit to bevel the edges of the depression.

I then set everything back up to ensure that the top of the nose gear actuator motor housing had plenty of space, which it did.

And I also checked that upper side holes provided the correct clearance for the main nose gear actuator attach bolt, which you can clearly see that it does below.

And finally, a shot from aft showing the clearance between the actuator motor housing and the sides of the NG30’s.

Here’s a couple of selfies that I took with my Darth Vader-lite gear (I figure every now and again I should show the FAA that I was the guy actually doing the work!).

And here are the depressions ready for glass after I refined the beveled edges with the Dremel tool.

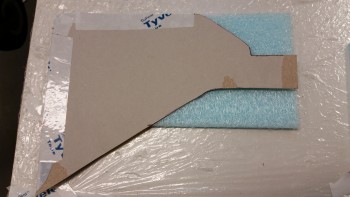

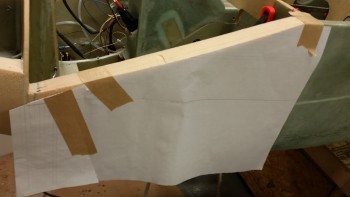

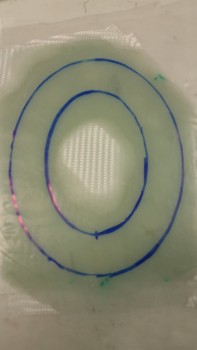

With the glassing ready to commence, I needed to make a template of the areas I intended on glassing. I wanted to stay clear of the gear actuator mounting brackets (that bolt into the 3 hard points) as to not mess up the set internal dimensions of NG30 components (e.g. relationship between actuator mounts at the aft end of the NG30s and the NG6B, nose gear strut pivot at the forward end of the NG30s).

And then I had to do something that I haven’t done in quite a while . . . cut glass! After making the template, I calculated that I needed to cut two 15″ x 15″ squares of BID for the pre-preg setup.

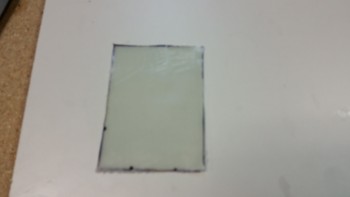

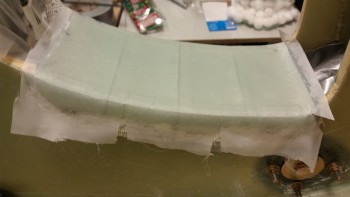

Here’s the 2-ply BID pre-preg (“poor man’s”) setup ready to go.

And then I added epoxy–using fast hardener–to wet it out.

Once the BID was fully wetted out, I used the glass template that I had just made and cut out the two pre-preg setups for glassing the NG30s.

I realized if I had staggered the sides a little better, I could have conserved more BID . . . oops!

I then cut out the two BID pre-preg setups.

I set the “oops” section aside so it will cure flat, at which point I’ll use some of it later on by cutting it into 1/4″ strips to use as filler material when I have to increase the depth of both my stock strut cover (SC) and nose wheel cover (NB) that I bought from Feather Light… tweaking these parts is a second order affect that is a result of having to cut the gear strut channel deeper to get the nose wheel to set fully into the belly of the plane–which differs from the original plans where the nose wheel hangs down below the airplane by just a bit.

I then laid up the BID pre-preps on the inboard sides of the NG30s. After ensuring the layups were good, I peel-plied the critical areas/edges. As per my plan, I was able to just skirt the edge of the actuator mounts by about a 1/16″ to 1/8″.

I noticed after laying up the glass, that the glass at forward top of the depression would not lay flat on the foam on the right NG30. I kept my eye on it and finally after messing around with the pesky glass for a few minutes, to no avail, I simply covered that area with Saran wrap, put some cushioning material on it to flatten out the invariable ridges from the plastic, and then threw a sandbag on it to keep the glass weighed down while it cured.

I then headed out to have dinner with my good friend Doug. Doug & I were Air Force Bomb Squad Technicians (Explosive Ordnance Disposal) stationed in England together back in the 1980’s. It was great seeing him & catching up, and since he’s a pilot, we had some good conversations about a variety of Burt’s creations!

When I returned home after having dinner with Doug, I knife trimmed & sanded the edges of the NG30 layups from earlier. I’m really happy with how they turned out & think that they will be very beneficial in their new state.

•••

30 October 2015 — Since yesterday was all about the inboard side of the NG30’s, today is all about the outboard side. My goal was to finish prepping the NG30’s so that they would be ready for install on the nose of the fuselage.

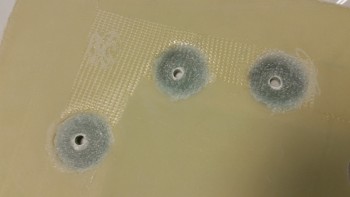

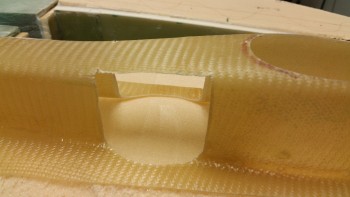

My specific steps today on the NG30’s was to fill in the 3 aft hard points with more BID “roundels” to bring the surface of each hard point up to the level of the surrounding NG30 surface. Why? Well, because I want to be able to use the correct washer and right now I either have to go with a smaller washer, or pack the hard point depression with flox before I add the washer. Thus, in my mind it made more sense to just add a few more layers of BiD into the hard points.

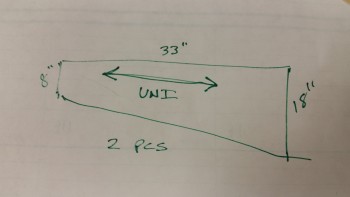

Since I’m adding glass to the hard points, I am following the advice that Jack gave me during a conversation a few years ago by adding 1 ply of UNI at a 45° bias angle from the F22 junction down toward the front of the NG30 (just aft of the NG8 screws). And then on top of the UNI will go 1-ply of BID that also goes right up to the NG8 area. To be clear, Jack had mentioned this as part of a few possible, but not “mandatory,” mods to increase the strength of the NG30’s. After reviewing my emails with Jack, and taking into account Jerry Schneider’s not too distant crunching of his stock NG30’s in his Cozy after a hard landing, I decided to employ all NG30 beefing up measures, weight be damned!!! (Forgive me Burt, for I have sinned . . . !)

The first task was to clean up the excess epoxy and prep the glass for adhesion using the Dremel tool. One point of note is that when I originally built these NG30 hard points, I did them to plans so I put weights on them to compress the glass. Boy did it ever! Plans say to glass in 15 plies, and I ended up adding at least another 3 plies. Well, the weight really worked, and the top of each hard point is still well below the surface of the NG30. Great for strength but bad for washer positions!

Below shows a progression of me cleaning up the NG30 aft hard points with the Dremel tool.

After I got the hard points cleaned up, I then sanded & prepped the surface of each NG30.

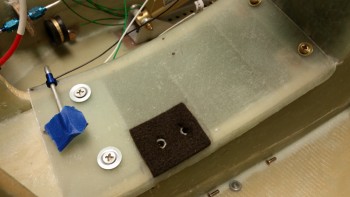

I then grabbed some scrap BID to use in the pre-preg for the hard point “roundels.”

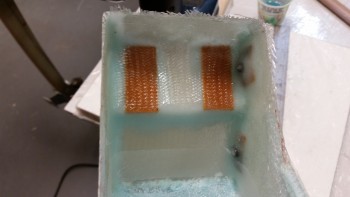

Here’s a shot of the BID glass “roundels” getting cut and glassed in place. I have to say that I thought most of the hard point depressions would handle another 6-8 plies of BID, but by the time I got to laying up the UNI pieces on each side, I would have to say I added about another 10 plies into each hard point depression.

Below is my finished NG30 quest for the evening. Each NG30 has 1-ply UNI at 45° bias (as per discussion with Jack) and 1-ply BID over the now surface level glassed hard points. Then I peel plied the entire layup mainly to match the original layup surface texture. Of course I’ll also be adding a number of BID tapes to these in the nose build process.

Next I plan on cleaning up the NG30’s by pulling the peel ply, razor trimming the edges and ensuring the layup was good.

•••

31 October 2015 — I started off this morning checking the NG30s’ outboard side layups. I failed to get this pic in the mix last night, but it’s essentially a bunch of heavy stuff that I balanced on separate 2x4s that are resting on plastic over the 3 hard points I just glassed, on each NG30.

When I pulled everything off, here’s what I found. Nice & flat!

And then I pulled off the peel ply.

And here’s the finished product: Edge-trimmed & sanded NG30s ready for attachment to the F22 bulkhead.

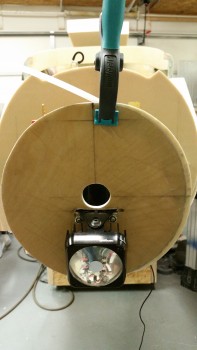

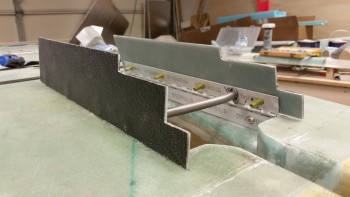

I re-drilled the gear actuator mounting bracket holes and put the NG30 nose assembly all back together to check fit & clearances. As you can see, it all looked good and went together smoothly. I checked the inside measurement of the NG30s and it’s almost exactly 3″, so the width is spot on (it would actually be a little tough to be off with the configuration as it is, with the mounting bracket spacers and all, but still, good to have the right numbers!)

Nose gear actuator, nose gear pivot (NG6B) and NG30’s ready for install!

Here’s a good shot of why I filled in the hard point depressions. As you can see below, the washers sit nice and level on the new glass and there’s no concern over torquing these very important bolts down to the right value. Nice, clean & EZ!

After all the work on the NG30s was done for the day, I spent about an hour upstairs researching parts & electrical connectors for the nose gear actuator (I really don’t care for Molex connectors in an airplane so my plan is to swap them out for AMP CPC connectors, as my buddy Dave Berenholtz did).

•••

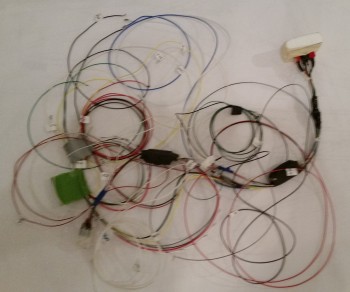

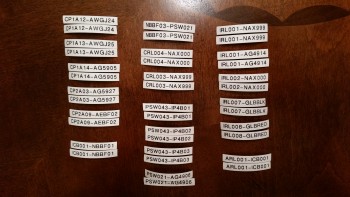

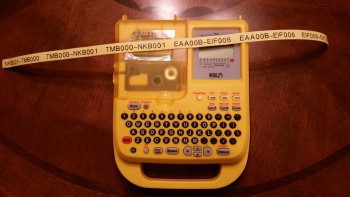

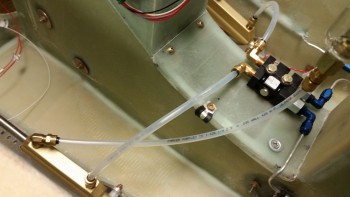

2 November 2015 — I spent the first half hour this morning finalizing my wire tracking & matching endeavor on the EZ Noselift Actuator wiring harness. I got down to 2 unclaimed wires, but wasn’t sure & couldn’t tell by the wiring diagram if they were supposed to be spliced together, although I suspected they were.

I fired off a quick e-mail to Jack Wilhelmson to verify a few things on the wiring and he e-mailed back shortly later to set me on the straight & narrow path! So all is good thus far in the wiring department for the nose gear actuator.

After I got everything straight with Jack, and as I was waiting for his e-mail, I was finishing up some research on Amp CPC connectors on Mouser.com. I ended up calling Mouser to confirm that I was ordering the correct stuff. After cracking the code on the various pins & sockets for the Amp connectors, I fired off my dorder to Mouser for Amp connectors to replace the Molex connectors currently used in the nose lift actuator system.

•••

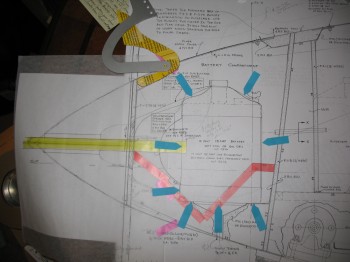

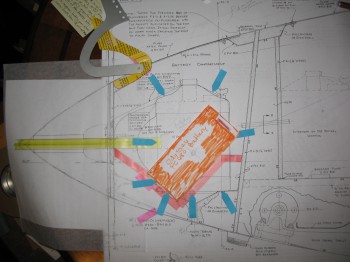

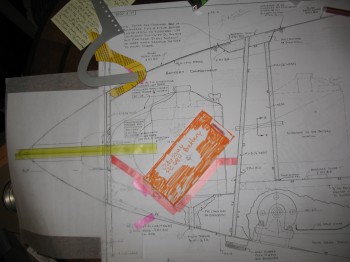

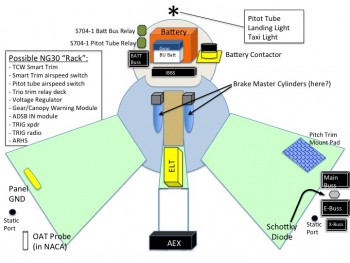

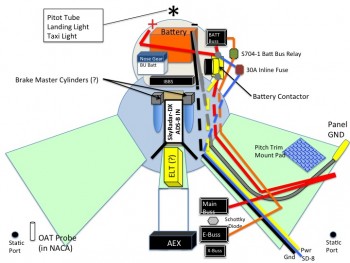

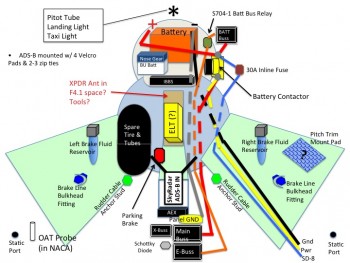

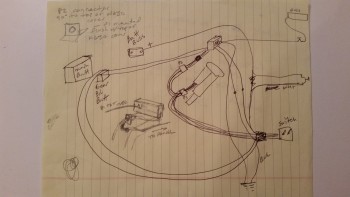

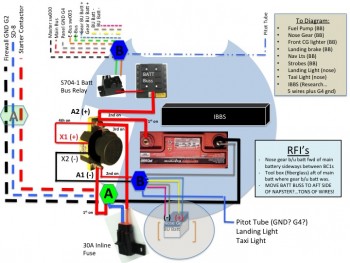

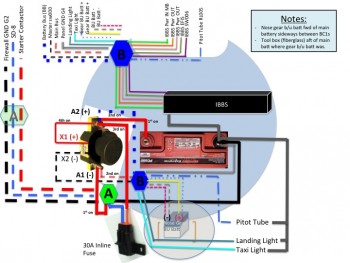

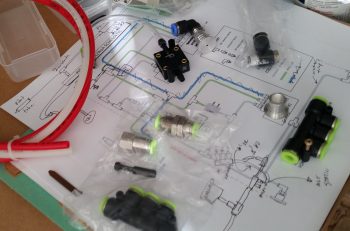

7 November 2015 — Today was about research and getting reacquainted with my electrical system. My specific interest was in figuring out what components, electrical & otherwise, that I was going to put into the nose.

Now I know a lot of my contemporary building buddies would whip up some awesome looking CAD diagram with exact dimensions down to 3 decimal places that looks like an engineer’s dream, but me being a former military “Powerpoint Ranger” and certified neanderthal, I simply added a slide depicting my thoughts on this matter onto the end of my ongoing notes for the nose build.

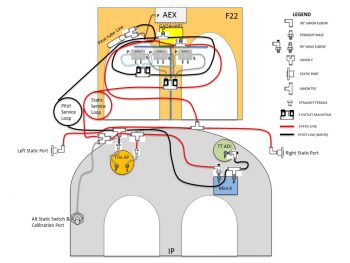

Again, this stuff is really just a mental thought jogger on what will most likely go into what areas in the nose, and get me thinking if there is any pre-actions or prep I can do as I build the nose. Some of the components I ID’d will be in the nose area, but aft of F22: OAT probe, static ports, buss fuse housings, etc. In addition, on many of the components I had to look up in my notes, emails, websites, install manuals, etc. to either confirm or research further why and how they were getting installed where.

Now, I mentioned CAD earlier, so speaking of CAD: The CAD program I was using to create my electrical diagrams was NanoCAD, as recommended by Bob Nuckolls in the AeroElectric Connection online forum. This was a great CAD program for electrical diagrams primarily because A) it was what Bob used to create all of them, and B) it was FREE! Unfortunately, my version of NanoCAD is no longer supported and apparently NanoCAD is now on Version 7, which costs a decent amount of money now to buy.

Well, no worries since I have TurboCAD, which I happened to purchase while I was in Tampa, Florida. But I didn’t have it loaded up on my desktop so I ended up spending a good half hour loading up TurboCAD and familiarizing myself with its features before I could open up any of my electrical diagrams. Why? Well, in a series of typical events, I had taken all the hardcopy printouts of my electrical diagrams down to my buddy Marco’s house while I was on leave from Qatar in March 2014, forgot them there, and haven’t been back to retrieve them yet . . . mainly because every time I go to visit him he puts me to work building HIS Long-EZ! HA! (Click here for the real story . . . )

Thus, to be able to make my annotations on my electrical diagrams on an actual sheet of paper, I had to be able to open the darn files to print them, which I am happy to report that I am now able to do.

In line with my reviewing my nose electrical components, my main preparation is in getting the nose gear actuator wiring sorted out to test it. I had planned on going over all my electrical stuff today since the epoxy was still curing on the canard and also, in part, because my AMP CPC connector order from Mouser was scheduled to be delivered today, which it was.

I checked out all the goodies from Mouser and pretty much solidified my plan for the wiring & connections for the nose gear actuator system.

Next I plan on wiring up the nose gear actuator & testing it out.

•••

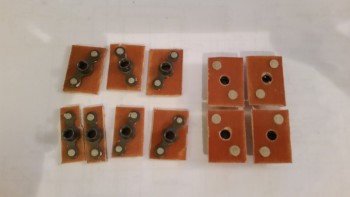

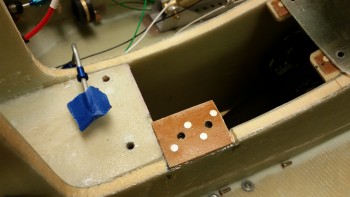

8 November 2015 — Today I cut out the 2 phenolic support pieces that will be embedded in the NG30 cover for the AMP CPC connectors.

•••

11 November 2015 — Today the UPS guy showed up with the battery charger I ordered from Amazon last week. I ordered this battery charger because in reading the manual for the Odyssey PC680 battery it stated that if the battery charge fell below 12.65 volts, than it needed to be charged before using it. When I checked the battery, the multimeter showed 12.57 volts, clearly below the threshold required to be able to use the battery as per the instructions.

Of course I knew I would need a battery charger eventually since the Odyssey PC680 is an Absorbed Glass Mat (AGM) type that is immune from acid spills and gas venting, and thus has some unique charging requirements to ensure the battery is maintained in an optimized state before it’s actual use in the Long-EZ. An interesting side note to this battery is that it can be mounted in any position.

Currently, the main reason I want to use the battery is to test the nose gear actuator. So when the battery voltage tested low I checked the Odyssey website for approved battery chargers. After assessing a few battery chargers online, I decided on this one and ordered it.

I hooked up the battery to the new charger before heading out to a meeting I had at the office. Before I left for my meeting I went upstairs and changed clothes –about 5 minutes– and when I did a final check before walking out the door the charger had already completed its first 2 phases and was in the basic charging phase. This was a good sign since the initial phases are conditioning cycles that bring a battery back to the point where it can simply be charged in phase 3, where again, my battery was before I even left the house. By the time I returned about 2 hours later, the battery was fully charged and was at 13.87 volts. Not bad!

I’m discussing the battery at this point since the short term use of the battery is to test the nose gear actuator (Chapter 13) while of course the long term use will simply be as the aircraft’s primary power source (Chapter 22).

•••

13 November 2015 — Today I worked on the nose gear actuator wiring.

My first task was to pull off the motor side Molex connector, since I’ll be replacing it with an AMP CPC connector.

I then double-checked the charge on my nose gear back-up battery. At 13.11V it looked good and seems to be holding its charge well.

While tracing out & connecting the wires for the nose gear actuator I was able to integrate & plan out the wiring for the gear & canopy warning module. Basically, I figured out that I can use the up & down limiter “micro-switches” on the nose gear actuator to drive the warning signals to my gear/canopy warning module. Of course the only issue is that I’ll need to order another AMP CPC connector. No worries really, since I was going to have to do some finagling with the thick power wires to get them into the 9-pin AMP CPC connector. A larger connector will be able to accommodate bigger wires.

•••

20 November 2015 — Today I knocked off another couple items on my nose build list by cleaning up some epoxy goo on the face of the F22.

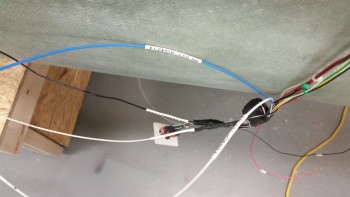

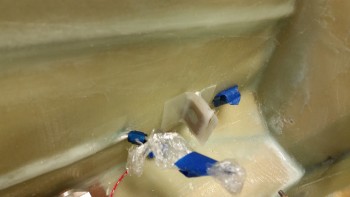

Then, while I was standing there looking over the F22 area, I realized that my internal brake lines were kinda hanging out into space. I wanted to secure them in place & protect them, so I grabbed a piece of nasty urethane foam and hacked it up and shaped a reasonable gap filler ramp on each side to slide in between the brake line, the fuselage floor/wall and F22, on each side of course. I’ll install these with a lot of messy micro and 1 ply of BID.

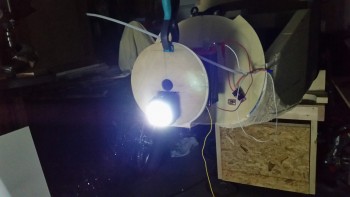

And then I (finally!) went ahead and finished wiring up the nose gear actuator to test it out. You can see the test in the video below:

Getting closer!

•••

21 November 2015 — I mentioned that I had updated my electrical component placement plan for the nose. I finished the final mods this morning and figured I would post it for you all to see.

•••

23 November 2015 — Today I turned my sights on the nose area, or F22 as it is right now. To prep the brake line secure and protect layup on each side, I first slid another 6″ of Nylaflow to jut up against the end of they current Nylaflow. A good portion of this new Nylaflow will get buried under Micro & glass.

I whipped up some thick micro and micro’d in the urethane foam piece with a good slathering.

I then laid up first the left side, and then the right side with 1-ply BID over the foam ramps. The popsicle sticks in the pics are holding the glass down that surrounds the upper brake line. I then applied peel ply to each layup.

I then turned my sights onto the F22 center strut. I sanded the forward face and then hit each back corner with the sanding black to radius it a bit for the glass tapes that will hold the nose gear frame (NG30s) to the center strut.

Here are the finished layups for the right & left side brake line secure, protect & route 1-ply BID.

Here’s a shot of the new layups from the front. Notice how the interior area forward of the instrument panel is clean & sanded. I spent a good hour getting this area sanded and in shape.

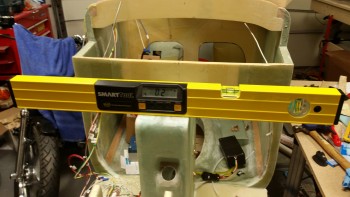

I then grabbed my trusty string and checked the CL alignment of the bulkheads.

I also removed the nose gear actuator from the NG30 frame in prep for glassing the NG30s to the F22 center strut, etc. Notice that I taped up the mounting brackets & hardware.

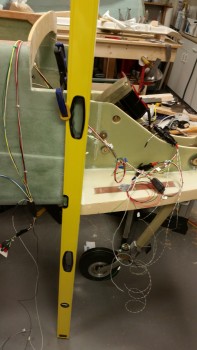

Also checked the left-right level of the fuselage across the longerons. Looks PDG!

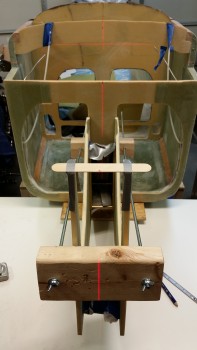

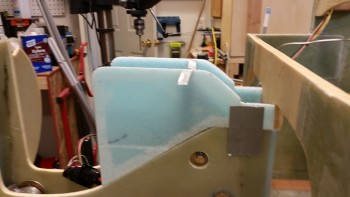

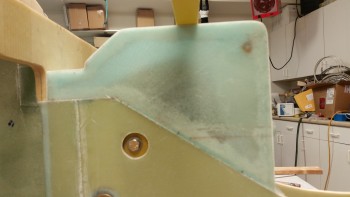

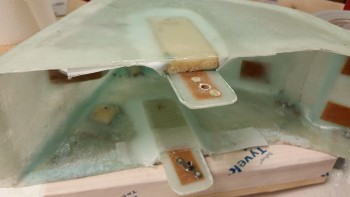

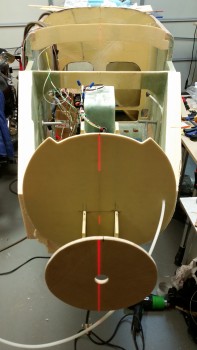

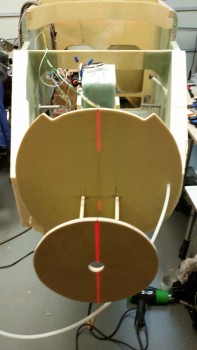

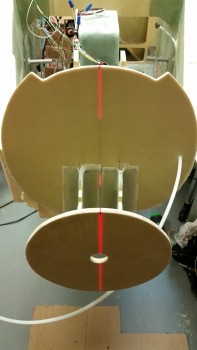

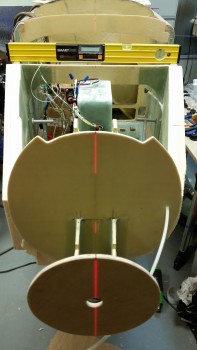

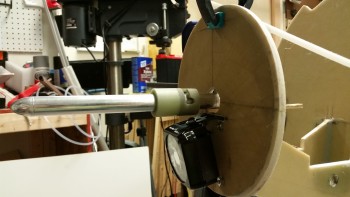

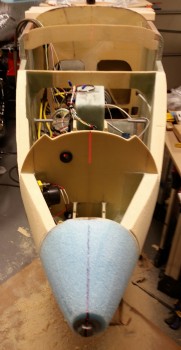

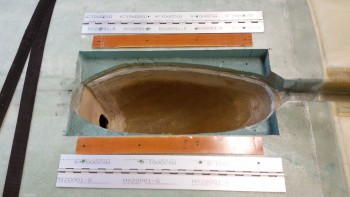

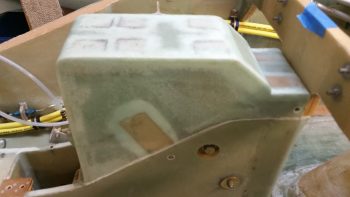

I then clamped up the NG30 nose assembly to F22 on the front of the fuselage to test out the fit & finish of the nose gear frame assembly. Now, this was just a dress rehearsal, trial run, etc. so I haven’t floxed or taped it on yet.

Here’s a bit closer shot. Amazing that although I built the NG30s back in 2013, this is the first time they’ve been mocked up on the nose.

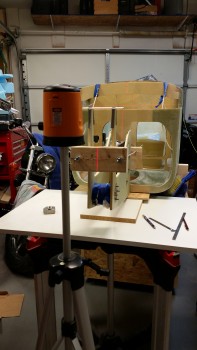

To really ensure everything is on the straight and narrow, I pulled out my (also) trusty laser level to shoot some laser lines. It took me about 5 minutes to get the laser set up and leveled itself.

I then fired a line at the CL of the fuselage and NG30 nose gear assembly. The laser line was off a very faint tad here & there, but in the end it all lined up, nice & centered!

•••

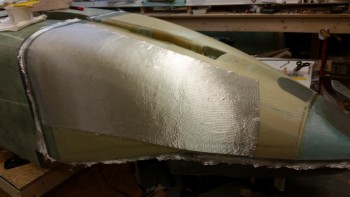

24 November 2015 — Today I started working the install of the NG30 nose gear assembly. I started by mixing up some MGS epoxy with fast hardener. I had already prepped the 2-ply BID prepreg setups for both the internal & external BID tapes for attaching the NG30s to the F22 center strut. I quickly wetted them out and then began mixing up some flox.

I applied the flox to the aft edges of the NG30s.

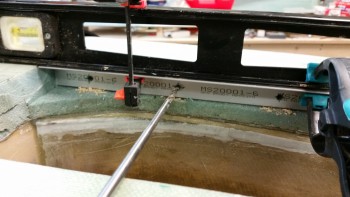

After applying the flox to the NG30s aft edges, I attached them to the front of F22 with the clamp and then marked up the internal 2-ply BID tapes and cut them to length: 13.5″ long x 3.3″ wide.

I then laid up the NG30 assembly’s internal BID tapes after applying pure epoxy to prep the glass surfaces.

After laying up the internal NG30 BID tapes, I did a final alignment check with the laser. Thankfully it was spot on.

I then laid up the external BID tapes that wrap around the aft side of the F22 center strut on the first inch and a half of each aft NG30 edge. Because of the clamp securing the NG30 assembly to the F22 center strut, I could only lay up the top 7″ of the external BID tapes. I’ll add the bottom external BID tapes later.

After I peel plied the external BID tapes, I was in the middle of adding the first of some peel ply strips to the edges of the internal BID tapes when I felt the epoxy cup in my hand getting really warm. I was able to get a little bit more epoxy on the center peel ply strip but I stopped when the epoxy started getting much, much warmer and was clearly heading towards exotherm.

Since the internal BID tapes will rarely see the light of day, I left them as is and didn’t mix up any more epoxy to add any more peel ply.

Here’s a shot of the left side external peel plied BID tape.

And an aft view of the external BID tapes.

I then fired up a heat lamp and took a break for dinner.

Upon my return from dinner I removed the peel ply from the external BID tapes.

I then razor trimmed the top area of the NG30s.

I then removed the one piece of internal peel ply, and then the protective tape around the nose gear actuator mount.

•••

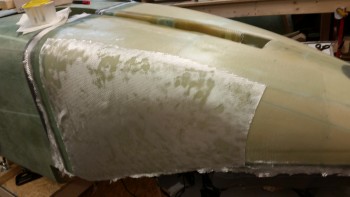

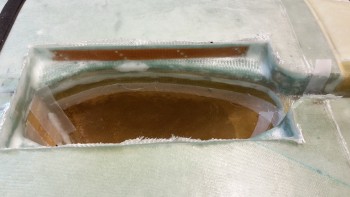

25 November 2015 — I started out today by setting up the prepreg BID for the lower half of the NG30 to F22 layup.

I mixed up some epoxy with fast hardener and wetted out the prepreg BID.

And then mixed up some flox and applied it to the corners.

Below is a shot of the 2-ply BID prepreg layup for the right external NG30 to F22 attach. I overlapped the bottom layup over the first (top) layup by an inch.

I then peel plied the layups. Note that I also laid up 2 plies of BID in the very bottom corner between the NG30 plate and the F22 plate.

While the NG30 glass was curing I started working on mounting the fuselage further forward on the fuselage dolly so that there would be plenty of clearance for the front wheel ingress & egress from the nose gear wheel well.

To move the fuselage forward I needed to cut another fuselage saddle wider than the current forward saddle. I marked up a piece of wood and cut it out.

I then clamped the old saddle over the new undrilled saddle. I drilled through the existing holes to make the new mounting holes.

Here’s the new saddle in place and mounted with the 5/16″ bolts…

allowing me to move the fuselage farther forward on the dolly. I also added another tie down strap.

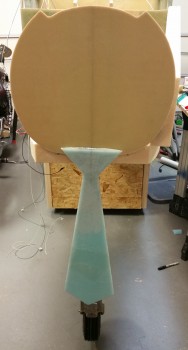

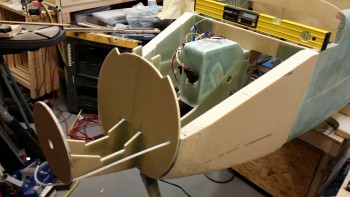

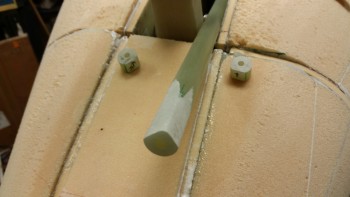

With the nose wheel clearance taken care of I started working on mounting the nose gear strut (NG1-L) to the nose gear pivot (NG6B). I mounted it temporarily using clamps, and spent a good 20 minutes getting it aligned down the center of the channel.

I also temporarily mounted the nose wheel to ensure their was enough clearance for the wheel in the wheel well. It was close, but there was just enough clearance aft of the wheel.

Once I got it aligned I loaded my drill with a 3/16″ bit and started to drill starter holes in each of the 4 holes in the NG6B.

I should probably offer a reminder at this point that I’m using Jack Wilelmson’s NG6B vs the NG6A (or the original NG6). The NG6B differs in that it uses two separate bolts to hold it in place –one from each side– rather than the single long bolt that the NG6A uses. This comes in rather handy if you want to remove the nose gear pivot after the nose is built. Unfortunately, the NG6A bolt can’t be removed easily after it’s installed since the bolt is too long.

The NG6B also comes with the 4 screw holes pre-drilled which makes it really nice when it comes to this part of the build!

My initial plan was to simply drill some starter holes since that would give me the exact locations of the screw holes. I would then finish drilling the holes on the drill press later. Well, as I was drilling the starter holes, it occurred to me that the bottom of the nose gear strut isn’t straight, level or even, so mounting this horizontally & level on the drill press table would not be an EZ endeavor. So, in the name of optimizing time and getting this done I went into Maverick mode and just finished drilling the holes with the power hand drill, freestyle.

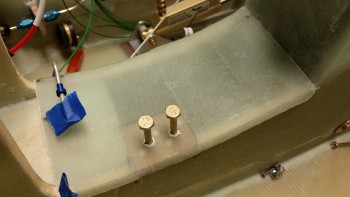

Now, I did use the drill press to drill the countersinks into the NG-5 plate. I screwed the NG-5 down to a 2×4 with 2 screws. I then drilled the first two countersinks, swapped the screws and drilled the last two countersinks.

Here’s the finished NG-5 plate screwed in place to the nose gear strut. The ring around the lower left screw in the pic below is because by using the countersink drill bit assembly on the drill press obviously works differently than using it on a hand drill, where with the latter when you press down on the plate it stops the support plate on the drill bit. When using it on a drill press you have to manually stop the support plate from spinning before engaging the actual bit.

All NG6 assemblies seem to require that the areas around each screw hole be ground down to allow the washers & nuts to fit. Below you can see that I Dremeled out the area around the hole on the left, while the hole on the right was not yet completed.

The aft holes seemed to be ok for now, so I just added some temporary nuts and tightened everything up. It all lined up great.

Here are a couple of shots of the nose gear strut in place.

I then started working on the 1/4″ 2024 aluminum skid plate that I’ll be mounting on the lower nose. I marked a cut line at 6.2″ and then cut it at 45° along this line.

Here’s the raw cut skid plate.

The skid plate will also serve as the mounting plate for the rubber nose bumper that my buddy Marco made for me.

I cut out a notch on the bottom of the NG1-3 bulkhead, or “Napster” as I call it, for the skid plate… using the skid plate as the template.

I then tested the fit. Not bad.

With Napster prepped, I then taped up the NG6B and its hardware in prep for installing Napster to the forward NG30 uprights.

I started prepping the 2-ply BID tape prepreg setups for mounting Napster to the NG30s.

I mixed up some epoxy with fast hardener and then made up some flox. I then applied a bead of flox to front edge of each NG30 upright.

Then I cut the BID prepreg setups to size.

And then laid up the BID tapes on the outboard sides of the NG30 uprights.

After a good night’s cure I’ll remove the NG6B nose gear pivot and lay up the inboard BID tapes to finalize the Napster bulkhead install.

•••

26 November 2015 — Here’s a couple of shots of the F1-3 bulkhead (“Napster”) attached to the NG30 nose gear box without the clamps.

After prepping the prepreg setups for the inboard NG30 uprights-to-Napster BID tapes, I then mixed up some more epoxy with fast hardener for laying up the inboard (NG30 uprights) BID tapes.

Below are shots of the flox fillets and the laid up BID tapes for the inboard BID tapes.

Here’s a shot of the final layup for the inboard BID tapes.

After laying the inboard NG30 BID tapes, I turned my sights on mounting the nose gear strut to the NG6B nose gear pivot.

I slathered on a bunch of flox all over the mating parts, then permanently screwed the NG5 (top) plate to the nose great strut and NG6B pivot assembly (bottom).

Although a little late for Halloween, this is a shot of “Scary Napster”.

•••

27 November 2015 — Since I had to remove the NG6B and gear strut assembly to glass the inboard F1-3 bulkhead (“Napster”), I started off today by greasing up the NG6B bearings.

Here’s an action shot of me greasing the bearings!

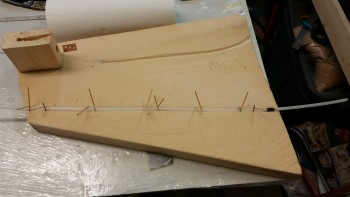

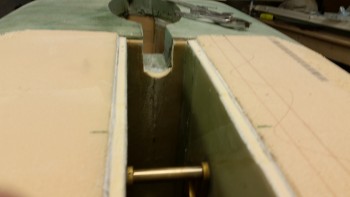

I then started on the gear strut channel that runs from F22 aft to the wheel well. The first task was to confirm the CL on the underside of the fuselage and then mark the cut lines.

I then cut the lines with the Fein saw. Exact precision wasn’t required here since most of this area will either be covered with the nose gear strut cover, or get cut out to make room for the gear doors.

And I cleared out the dead glass, foam, etc.

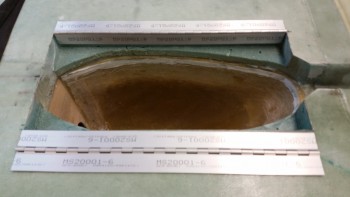

Here’s a shot of the nose wheel spacing (look with aft at top of pic).

Ok, some of my fellow builders have discussed the issue of the stock nose wheel sticking out down below the bottom of the fuselage, normally around 1/4″ to 1/2″. Fortunately, I don’t have this issue on my bird, and it’s all really because of a serendipitous reason.

Ok, some of my fellow builders have discussed the issue of the stock nose wheel sticking out down below the bottom of the fuselage, normally around 1/4″ to 1/2″. Fortunately, I don’t have this issue on my bird, and it’s all really because of a serendipitous reason.

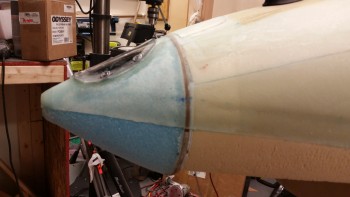

When the foam called out per CP 34 back in 1982 changed from the old PVC to the now standard Divinycell, the foam for the fuselage bottom changed from 1.6″ to 1.75″ thick. Thus, when I built the F22 to the plans height dimensions the fuselage bottom ended up almost 0.2″ lower than the bottom edge of the F22. I don’t remember all my reasons for doing so right now, but I didn’t sand the bottom fuselage surface to blend into the bottom of F22 (you can see this in a couple pics above). One reason I left the bottom fuselage foam at 1.75″ was so that the entire nose structure would be a bit lower.

Now, let’s fast forward to a few days ago when I mounted the NG30s to the front of F22. To keep the bottom of the fuselage even, I dropped the NG30s even with the fuselage foam. Obviously when I did this it dropped the Water Line (W.L.) of the nose gear pivot down by about 0.2″. This time around, I was hoping that the lower fuselage/nose gear box would result in an angle that would avoid any further messing around with the gear strut, etc. to fix a less than shy nose wheel.

Well, it did. When I cut the nose gear strut channel, mocked up the nose gear, and checked the spacing of the wheel in the wheel well I was pleasantly surprised that with a stock gear strut channel (read: no more cutting or layups) my nose wheel sunk out of sight into the wheel well.

Of course, with the wheel sinking deeper (meaning up) into the nose wheel well it means that the standard nose wheel cover (NB) isn’t deep enough and will have to be increased height-wise.

Here’s a shot of the nose gear in the wheel well.

And a couple shots of the nose gear strut mocked up [Note that I removed the temporary NG6B shipping bolts and installed the final AN5-15A bolts and AN970-5 washers when I remounted the gear strut].

I also pulled the peel ply from the inboard BID tapes holding Napster to the NG30 uprights.

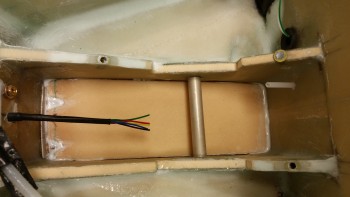

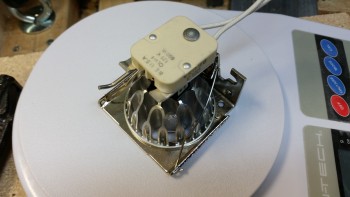

I then prepped a microswitch for mounting on the nose gear actuator as a part of the nose gear warning system.

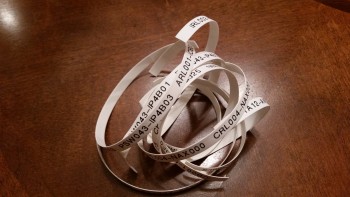

I crimped up some 22 AWG wires for the nose gear warning system. These wires will be ran through the bigger AMP CPC connector that I recently ordered from Mouser.

These wires are also for the nose gear warning system, but they mount into the opposite side AMP CPC connector and will terminate at the gear & canopy warning module.

I also took the opportunity to re-terminate the socket connectors that come from the nose gear actuator side of the P1 connector.

Here’s a shot of the P1 connector. After I confirm that all the connections are good I’ll zip tie the wires and permanently mount the cable clamp.

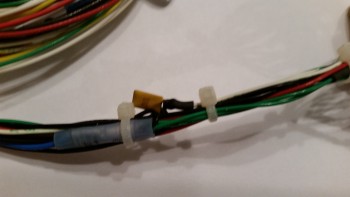

Also, the two power 12 AWG wires (Red & Black) coming from nose gear actuator motor in the end were just too big to fit into the back connector plate. I tried slightly expanding a couple of connector holes with a #29 drill bit to start out with, which worked well. In the end though, I finally threw in the towel and ended up chopping off the last 3″ of the power wires and replacing it with a 3″ piece of 14 AWG wire. You can see the connectors in the picture below where I spliced the new wires into place. After messing around with the unruly wires, it was great to work with wires that simply went where they’re supposed to!

•••

28 November 2015 — I started out today working on permanently mounting the NG15 (technically the MKNG15B) casting to the end of the nose gear strut.

I attached the stainless steel foot rest after slathering up all the surfaces with flox. Here’s the end result.

I find that both the original plans and a lot of vendors that sell parts for the Long-EZ often call out for bolts that are simply too long. The same holds true for mounting the NG15 in that CP#51 recommends that builders upgrade to AN3-14A bolts, which were way too long. So I ended up using AN3-12A bolts like a number of other builders I know.

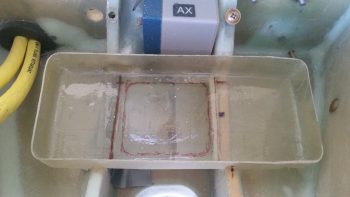

As the flox cured I worked on converting the P2 connector on the AEX from a 9-pin Molex to a 9-pin AMP CPC connector. Below are a couple of shots mid-mod.

I then wrapped the wires with self-amalgamating (“centerline”) tape.

And finalized the conversion by mounting the cable clamp.

Now, I’m going to quickly get on my soap box. I’m incredibly grateful as an airplane builder to have a company like Aircraft Spruce to buy the stuff required to build an airplane that would be close to impossible to find anywhere else.

With that being said, as much money as I’ve spent there over the past 5 years, you’d think that when buying an almost $100 piece of foam that is supposed to be 24×48 inches, that I’d actually get what I paid for… not one that is short and malformed on one end and cracked at the other corner on the other end.

The good news is I still had enough to cut out the nose panels, although the foam that ACS delivered is unsat & not cool.

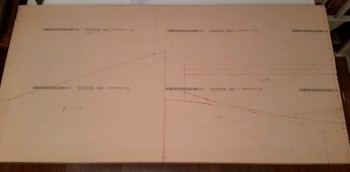

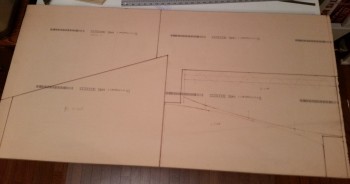

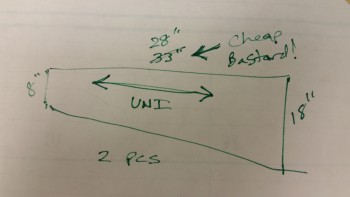

Now, back to the build. Since I only bought one piece of this foam, I needed to squeeze every square inch out of it that I could. I spent a bit of time figuring out a cut sheet to optimize the foam usage. I came up with the configuration below and marked up the foam.

Once I verified the dimension were correct I marked the actual cut lines that I would use for the initial cutout of the panel with my Skil saw.

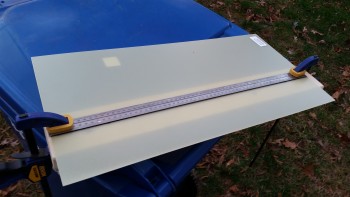

I then set up a cutting table out back and cut the panels out.

And here are the results.

•••

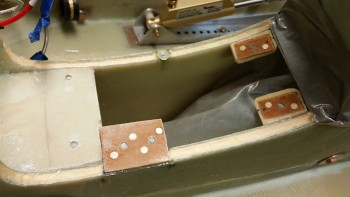

29 November 2015 — I started off today by marking up the area on the floor pans that gets dished out. At this point, it was just for planning purposes since my main goal for today was to figure out the location to mount the rudder/brake pedals. Once I figured out where the rudder pedals would go, I could then finish dishing out the floor pans and prep them for install.

I also did the final mark up on the side panels that go between F22 & Napster.

I then sanded the aft end of the floor pans to a 10° angle.

And cut & trimmed the left side panel (not pictured). Although I widened my fuselage 1.4″ at the front seat back, my F22 is pretty much standard size. So cutting the side panel to the listed dimensions should have gotten it really close to fit into the current F22-NG30-Napster configuration. It was close on the aft side and ok on the bottom edge, but the front was pretty far off. The angle called for was just too severe as compared to the actual F1-3 Napster aft lean.

After messing around with the side wall for a while, and finally getting it into an acceptable shape to fit into place, I started mocking up the rudder pedals. I spent a good hour doing research: comparing my buddies’ build sites, re-checking the plans, etc. as I tweaked the final location of the pedals.

I also climbed into the fuselage and tried out my feet location to double check as well. Now, a couple things of note are that my rudder pedals are adjustable, but of course that’s only for fore & aft. Also, the rudder pedal plans specifically state to keep the pedal 1-1/4″ away from the sidewall. Part of the reason for me doing so much cross-checking in my research is that this 1-1/4″ clearance with the sidewall is a tall order in such a small space as the nose, especially since with the Davenport nose the sidewalls stay rather thick. The bottom line is that as long as I have a good clearance with the sidewall, the 1-1/4″ clearance requirement is just not happening.

The main reason for ditching this lofty clearance requirement is that one of the really nice features of the Long-EZ is to remove your feet from the pedals while in cruise flight and resting them adjacent to the pedals, wherever they happen to be mounted (some folks mount them on the inboard side vs the outboard plans side). Clearly, with the pedal mounted more towards the center of the foot/leg opening in F22, that diminishes the comfort of the pilot (me!) during flight. So again, I’m chucking the 1-1/4″ clearance for a more reasonable one considering the tight quarters in the nose.

BTW, if you look in the pic below you can barely make out the gap in the junction between the front of the sidewall foam & the F1-3 bulkhead, aka Napster.

With compromises on side clearances made with the rudder pedals, and thus the mounting location on the floor pans pinpointed, I marked around the perimeter of each phenolic pedal base (that comes with 3 x K1000-3 AN3- nutplates pre-installed…nice!). I then used my router to remove about 3/32″ of foam so that each base would lie perfectly flat with the top of the base level with the surface of the foam, allowing a minor clearance for application of micro as well.

Here are the pedal bases fitted in the their mounting recesses in the foam.

As I mentioned at the start of this post, with the location of my pedal bases set & confirmed, I could now dish out the inboard side of each floor pan. I started by removing about 90% of the material with a coping saw.

I then used my half-moon Perma-Grit tool to remove the rest of the material and sand the dished out area to its final shape.

After the inboard edges were dished out, I then expanded the depressions in the foam for the K1000-3 nutplates just a tad to provide the proper clearance when the rudder pedal base plates are micro’d into place in the floor pans.

Since it was raining outside, I had to reorganize the shop a bit & play musical chairs with my motorcycle to get access to my glass cutting table. Once table access was “granted,” I then cut out 2 pieces of BID for each floor pan and 3 pieces of BID for each sidewall piece.

While cutting the BID, I used up the final bit of glass on the roll mounted in my cutting table. I loaded up another roll, and have to say this time it felt really good because I knew that this would be the last roll of BID that I will use for this project!

Now, the plans call for 2 pieces of BID for each sidewall piece, so why am I adding a third piece? Because I’m breaking the rules. The plans for the Davenport nose say specifically NOT to dish out the side walls, but having nearly 2″ thick Divinycell side walls for an 11″ nose extension is a bit of overkill in my opinion. Since the foam is so thick, when matching up the sidewall with the opening in F22, the plans do call out for dishing out the side wall to ensure a smooth transition with inboard edge of the F22 sidewall.

Thus, my plan is to leave the bottom of the sidewall the normal width for this install, but in the area above where the sidewall gets dished out, I narrowed the sidewall foam to 1.1″. I figure if the Ronenburg extended nose and others call for 0.8″ thick sidewalls using blue wing foam, than 1.1″ thick Divinycell on the top half of the sidewall with an extra ply of BID will be plenty strong.

With everything prepped on the floor pans, after one final fitting check, I whipped up some micro and slathered it on the surface areas that would mate with the existing nose components. Since the 10° called out for in the plans is just a tad bit too severe, I needed to fill a about 0.050″ gap in-between the floor pan and the F22 bottom front, so I mixed in some flox to create some flocro to apply to the back edge of the floor pan. That explains the slightly different consistency & color you see between the edge micro and the back flocro that is visible in the pic below.

I mounted the right floor pan first & then clamped it into place.

I then micro’d up the edges of the left floor pan and installed it. When I pulled the clamp off of the right floor pan to install the left one, there was very slight gap that was created between the NG30 and the floor pan. Although I had planned on glassing the floor pans this evening, it got me to think that I wanted the seams as tight as possible, so I simply re-clamped both floor pans together and decided to let it all cure overnight.

I then got to work sanding the phenolic rudder pedal bases with 100 grit sandpaper. You can see below that the left base is sanded while the right one isn’t.

I then filled the K1000-3 nutplate bolt holes with saran wrap and did a final test fit for each rudder pedal base into the floor pan foam. I’ll micro in the pedal base plates just prior to glassing the floor pans.

•••

30 November 2015 — I started out today by adding micro into the routed beds I made for the phenolic rudder pedal bases.

I then spread a fine coat of epoxy on the bottom side of the pedal base and mounted it in the floor pan. I also added a micro fillet in the corners around the perimeter of the floor pan.

The last step I performed when I was laying up the floorpans was to add a 3.5″ wide and 2.5″ high 2-ply BID layup between the aft bottom of the F22 center post and the fuselage floor.

Here’s a shot of the glassed and peel plied floor pan.

To ensure that each embedded rudder pedal base was perfectly level, I taped up a couple pieces of scrap wood with packing tape and then weighed them down over the rudder pedal bases.

Here’s a shot of the weighed down rudder pedal bases.

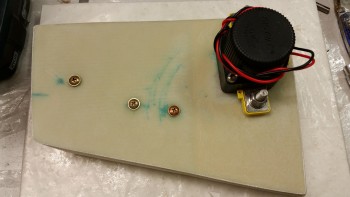

While the floor pan layups cured I started back to work on the nose gear electrical system to finalize the conversion of the connectors to AMP CPCs. I finalized converting the switch side (vs motor side) main connector P1 while concurrently cleaning up the wiring by zip tying the wiring. I also cut all the terminated wires to the same length.

Here’s a shot of the P1 connector (motor) and P2 connector (AEX) connected together.

After a good 3-4 hours of cure time under a heat lamp, I pulled the weight off the rudder pedal base, razor trimmed the overhanging side glass and pulled the peel ply. I also spent a good amount of time cleaning up all the peel ply goobers as well.

I set the heat lamp up on the other side and ended working another 3-4 hours on the nose gear electrical connectors before cleaning the right side. I still have to clean up all the peel ply boogers, but I’m calling it a night.

•••

1 December 2015 — I had meetings and appointments today so I didn’t get back to work on the project until after 1700.

The first thing I did was to test out my new wiring connectors on the nose gear actuator. I double checked the connections, checked the battery voltage (12.86V) and then hit the switch. Ah, the motor came alive and down it went. Good deal. Then came the inevitable gotcha. I threw the switch the other direction to raise the actuator arm and heard . . . nothing. I double checked my wire connections, A → B, C → D, n → ∞, and all looked good.

So I tried it again. Nothing.

What ensued was about a 4 hour troubleshooting session where I did continuity checks on every single wire connection point, every run from starting terminal, through connectors, to the end connector and everything toned out perfectly on the Fluke. I checked the internal contacts from the P2 connector to the internal contacts on the AEX board. All good. I recharged the battery while I went out to the grocery store: fully charged at 13.23V, and still no up travel.

I reread Jack’s directions and happened upon a point of note about damaged microswitches. Since I now had extra I figured it wouldn’t hurt. When I started removing the microswitch on the right side facing the front of the unit, after marking its location of course, it literally crumbled in my hand. Not sure why that happened, but I replaced it. The good news is that I was able to reuse the lever arm from the newly deceased switch on the first switch body that got sucked into the ‘actuator of destruction’ and lost its lever arm. So I’m still down only one micro switch, but unfortunately the switch replacement still had no affect on the actuator being able to return to the up position.

Having exhausted every troubleshooting technique, and checking, double-checking and triple-checking every connection and continuity of wiring, I figured it was time to punt.

I’ll call Jack tomorrow to figure this thing out.

I took a break in the middle of the nose gear actuator troubleshooting saga above & spent about 15 minutes cleaning up the peel ply snots and edges of the right floor pan layup. Now both floor pans are ready for next steps.

Later in the evening, and I do mean late, with a fair amount of frustration with the nose gear actuator, and weary of chasing electron phantoms and wire ghosts, I decided to roll up my sleeves and at least get something glassed and curing so the night wasn’t wasted.

I turned my sites on the backside of the F4.1 (old F6) mini upright bulkhead that gets mounted to the aft side of the NG30 uprights. Although I keep wanting to write “aft,” I say “backside” because the side I’m glassing is not visible once glassed but actually faces forward. The F4.1 gets a 2-ply BID layup, and I’ll be adding two approximately 1″ wide strips on top and bottom as reinforcements for the velcro slots that will be used to mount the Radenna SkyRadar-DX ADS-B IN receiver.

Also on the list are the BC1’s, which are really a continuation of the NG30s into the forward battery box area just foreword of the F1-3 bulkhead (Napster). Since I will be mounting a retractable heated pitot tube, I had to mount the battery in a very specific location. This means that securing the battery will not possible in the usual Long-EZ fashion of simply strapping it to the nearing bulkhead. In the original plans that was a big function of the F6 bulkhead, since the battery was located immediately aft of F6 and was merely strapped to it.

My battery, for lack of a better description, will be out in free space. To ensure it stays in place I’ll be using a 2″ wide military grade web strap with a metal clasp and about 6-8″ of Velcro that will wrap around the center of the battery, holding the battery to the BC1s. But how you say? I will have a metal tube that is mounted between the BC1s, right under the battery. Since the tubing is clearly strong enough to hold the battery in place, I just need to ensure that the BC1’s are strong enough. Thus, I’ll be adding a 5-ply BID pad to both the inboard and outboard side of each BC1. The outboard glass will never get disturbed once glassed, while the inboard sides will be drilled to the diameter of the metal tube along with the BC1. In addition, I’ll have a thinner version of this type strap running around the battery from side-to-side.

In preparation, I used some pulled peel ply from the floor pans to make up a small template for the 5-ply BID pads. I cut 10 small scrap pieces of BID and stacked them 2 plies deep in 5 stacks in a prepreg setup. I also cut 2 plies of BID for the backside F4.1 layup.

BTW, the 5-ply BID reinforcement pads are shaped the way they are to not only reinforce the battery mounting cross tube, but also to allow room for the center H100 foam piece that will get mounted in the channel between the BC1s, just below the 5-ply pads.

I mixed up some epoxy with slow hardener and wetted out the F4.1 layup and the prepreg BID.

As you can see, I continued to wet out the F4.1 layup while also using my template to mark up the 5 sets of BID for the reinforcement pad on the outboard BC1s. [Note: Since the F4.1 is H100 foam, I didn’t use micro to prep the surface since the foam is so tight grained it merely laughs at micro).

I cut out the 5 BID pads for the BC1s.

I continued to work the F4.1 layup making sure it was completely wetted out in-between the different steps on the BC1 BID. After applying a thin layer of epoxy on each layup area on the BC1s, I then laid up the BID pads one by one on the surface of the BC1s where the battery tie down tube will get mounted. I split the last 2-ply BID prepregged pad for the fifth and final ply on each BC1.

I then removed the final top piece of plastic on the 5-ply BID pads.

I added the approximately 1″ x 3″ reinforcement ply both top & bottom on the F4.1 and also peel plied the BC1 5-ply reinforcement pads. I applied the peel ply a little wet since the 5-ply BID pads are thick and I wanted a good smooth transition between the pads and the original surface of each BC1.

I finished wetting out the F4.1 reinforcement pads and covered the BC1 assemblies with plastic Saran wrap.

I then cut a piece of peel ply from my roll of peel ply and began to prep it for F4.1 by taping a 3/4″ block of wood to the end of it. This wood will serve as a weight to keep the glass conformed to the curved bottom end of the F4.1. [Note: The reason the bottom of my F4.1 plate is curved is because I rounded all the corners on my NG30s to minimize any potential stress points, and because I’m just damned fancy . . . haha!]

Note that I have the F4.1 work piece sitting atop the BC1 assemblies.

Below is the peel ply applied to the F4.1. I taped it on the top side with the weight pulling the glass over the curved surface on the opposite end (nearest the camera). The block of wood is not very heavy of course, but it is just enough to keep the glass conforming properly (read: “attached”) to the curved bottom end of F4.1.

I then careful stacked some blocks of wood around the F4.1 layup.

And added a few heavy items to weigh down the 5-ply BID pads laid up on the BC1s. Now, I didn’t use something bulky like a gallon paint can to weigh this thing down because I wanted it open so I could aim a heat lamp at it without all my heat rays getting blocked.

Since I had a good little bit of epoxy left over, and I hate wasting epoxy, I grabbed some foam out of my scrap pile to make up a small 3″ wide by 6″ long 1/4″ thick “draft plate.” This plate will sit immediately above the NG6B nose gear pivot and will keep the cold draft air coming in to a minimum. My buddy Marco came up with the idea and since it’s a good one, I’m copying it! You can check out his version of this here.

This is regular 1/4″ PVC foam, so I micro’d it with slurry and then filled in the holes with thick micro. I then laid up 2-plies of BID, and since it will be getting glassed into a very tight spot between the NG30s I peel plied it so that it I could have BID tape coverage anywhere I needed as I attach it.

•••

2 December 2015 — I started out today by cleaning up the layups from last night. I pulled the peel ply, razor trimmed & sanded the edges.

Then it was time for round two. I cut out the pieces of BID for the other side of the draft plate and for the battery mounting tube 5-ply reinforcement pads. I didn’t glass the face of F4.1 since that occurs when it gets mounted to the aft side of the NG30 upright arms.

I then mixed up some epoxy with slow hardener and wetted out the BID.

The layups followed the same flow as yesterday. Since I wasn’t in a hurry for this layup to cure I didn’t use a heat lamp… thus I went ahead and weighed it down with a gallon of paint.

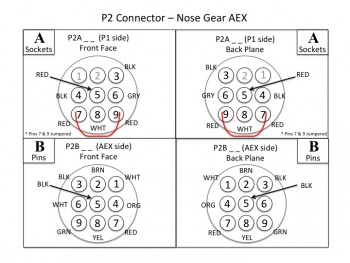

Later in the evening Jack Wilhelmson returned my call. After telling him the symptoms, he diagnosed the problem as me mixing up some wires on the switch side of the AEX P2 connector. Sure enough, after we got off the phone I checked the wiring and had wired up the connector in the mirror image of how it was supposed to be.

Thinking that I had indeed found the problem, and then remedied it, I wired it all back up. It just so happened that the last step was to connect the AEX hot power wire to the battery. Well, when I did I was met with a distinct & resounding “POP” sound. Initially, I thought (and hoped) it was the 5-amp inline fuse that sounded off. But alas, it was something on the AEX board. I couldn’t see any physical damage but when I cracked the case I certainly could tell that I had let the smoke out of one the components by the smell.

Ok, so during our discussion Jack had told me that if no AEX unit is used then pins 5 & 6 on the P2 connector require a jumper across them. I disconnected the AEX and then rigged up a jumper across pins 5 & 6. I rechecked the rest of wiring, connected power and then hit the up switch.

Nothing.

It’s late in the evening now so I’ll have to wait until tomorrow to give Jack a call back and confirm both the AEX status and how to fix the persistent issue with the nose gear actuator wiring.

•••

3 December 2015 — I think the following account should be titled, “The Anatomy of a Repair”

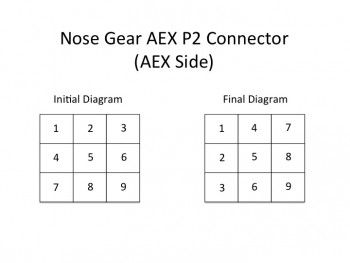

I had committed two grave sins in the wiring of the AEX P2 connector, one on each side. On the switch side I found pin 1, inserted that wire and then started filling in the wires per color from pin 1, first across and then down. The only problem was that my first direction was as it should be if I was looking on the FRONT of the connector face, versus the mirror image it should have been on the back plate of the connector. Ooops. Well, as I said yesterday, I caught that after my discussion with Jack and remedied it.

What I didn’t catch was the wiring mistake I made on the AEX side of the P2 plug. When I had original diagrammed out the connector pins for that side, I realized that I hadn’t made the diagram in the normal top row=1-3, middle row=4-6, bottom row=7-9 pattern. If you took the diagram and flipped it 180° from the upper right corner down to the lower left corner, that is what I ended with: column A= pins 1-3, column B= pins 4-6, column C=pins 7-9. Thus, when I wired it up (mistake #3 actually, since it was LATE at night) I had the mental picture of the initial diagram (left below) in my head, not the correct one (right below).

I got ahold of Jack later in the afternoon to figure out the wiring issue with the electrical nose gear actuator. With the AEX presumably Tango-Uniform, I thought that perhaps I needed another jumper on pin P2 along with pins 5 & 6. I wasn’t sure about the jumper situation due the fact that since I ordered the AEX with my initial order of the gear actuator, I never received a jumper plug.