Chapter 23 – Engine Installation

This page covers the installation of the engine, and also discusses firewall component placement, firewall pass-thrus, engine compartment hose requirements, firewall/engine electrical wiring requirements, upper cowling fitting, baffling requirements, lower cowling fit and air intake (fuel injection servo & RAM air) configuration.

10 April 2018 — Today I did some major spring cleaning on my shop today in prep for the engine install. I pulled a ton of stuff that I had buried against the wall that all in all still stole away 2 feet of depth on that side. I also removed a couple of high shelves and the 4 padded hooks I had up high for the canard, since it won’t be going back up on those hooks.

After a number of hours I was finally ready to move the fuselage out and put it back in the shop nose first. Here’s some pics of that short trek.

And a head on view of the fuselage’s new setting for a good while.

And an aft view.

I received an order from B&C with my engine ground strap, a couple of oil filters and a couple of the shorter Gates 7312 alternator belts. Before I got to moving the engine around I went ahead and slipped a new alternator belt into place.

Another shot of the new alternator belt in place.

Before I mounted the engine mount to the engine, I reviewed my notes. One Canardian had a trick he swears by using a “silver bullet” . . . You start with a standard 7/16″ bolt.

Chop the head off and grind it into a bullet looking pin. Now, he said 2-3″, but I don’t know what engine he was installing. The concept is simple, use the silver bullet to align the last two Lord rubber vibration dampener assemblies (one at a time) to the engine mount holes and then press the actual bolt in behind it, pushing the silver bullet out the other side.

The concept works great, but for an 320 case I think 1.5″ is the max length you can use since there’s not enough clearance on the other side. The one I made is about 2-5/8″ long and would get blocked from coming out the other side by some part of the engine.

So I didn’t use the silver bullet, but installing the engine mount to the engine versus mounting the engine to the engine mount with the latter pre-mounted to the firewall made it EZ enough anyway (albeit, still a ton of the usual fiddling about).

I had bought 4 castle nuts to use but I will say that I’m wimping out on using these at every point, especially under cylinder #4…. no way. So I put a mini-order in with ACS for two AN363-720 lock nuts as called out for in the Long-EZ plans.

Also, for a newb like me, I was concerned at first that my AN7-35A engine mount bolts weren’t long enough since I couldn’t get a thread showing until I compressed the installed dampener mounts a bit with squeezes clamps. However, in the end I needed to put 2-3 washers on to keep the cotter pin hole within the castellated part of the nut and not end up well past it when all was properly torqued (450-500 in-lbs).

I really don’t like doing things twice if I can avoid it, and I was going to make every attempt to make this engine mount install onto the motor my last one. But alas, it was not meant to be. While doing a good round of patting myself on the back for a job well done … haha! I noted that fuel pump looked awfully close to the engine mount… REALLY close as a matter of fact. Well, when I tried to thread in the FUEL OUT fitting onto the pump the engine mount wasn’t having any of it.

Thus the engine mount will have to come off at least once more AND I have to buy another 90-150 degree extended fitting (which means steel now) to get by that engine mount reinforcement tube. It will be a really tight fit, but if the fitting goes in first I don’t foresee any clearance issues . . . again, just all really tight (but then again, we’re talking about a Long-EZ here! Everything is really tight clearances…)

•••

11 April 2018 — My goal today was to get the engine mounted. Having the engine mounted for a bit will again allow me to figure out firewall component placement, firewall pass-thrus, the engine compartment hose requirements, firewall/engine electrical wiring requirements, upper cowling fitting (specifically for canopy/D-Deck angle), initial baffling requirements, lower cowling fit and air intake (fuel injection servo & RAM air) configuration. Then I’ll remove the engine and mount it to an engine stand.

Since A) I needed to remove the engine mount from the engine to get the fuel pump OUT fitting installed, and B) do a final clean and painting of the engine mount, I decided since that since the engine mount was secured in place for the moment that I would trim down 3 of the 4 engine mount stubs to allow for clearance of the firewall face’s Fiberfrax and 6061 aluminum sheet covering. About an 1/8″ at most getting trimmed off any of the stubs… with the top left already short enough for clearance.

I cut and placed a box that I had just received the second shipment of hoses and hose end fittings from Summit Racing (pretty much finalizing all my hose/fittings orders) over the engine mount/accessory case to protect all of it from sparks and metal debris.

Here’s a closeup of the right side engine mount stubs that needed just a hair trimmed off the front side.

I then spent about half an hour trimming them all up.

Here the right side stubs are trimmed up and filed smooth.

On my errands yesterday I picked up some hardware and some Automotive & industrial strength fast-drying White Rustoleum paint. I spent a good 30 minutes sanding down the engine mount surfaces with 220 grit sandpaper. Then I filed off a couple very small weld spatters that I missed before, then washed in hot water and Simple Green. I then let it air dry.

While the engine mount air dried I spent a good 3-4 minutes shaking the can to mix up the new paint… in painting, preparation is everything, right?! I then started spraying. It looked good and sprayed like normal spray paint, but then about 5 minutes into painting the bottom side of the engine mount… apparently my normal spray paint decided it wanted to be a can of textured spray paint. Within a matter of seconds I had the bottom, bottom right corner and right side of the engine mount peppered with what looked like textured, speckled paint.

Needless to say I was quite pissed. My saving grace was that this was fast drying paint, so after about 5 minutes I felt a spot and it was what I considered in it’s green state. Another minute more and I was able to rub down the surface with a paper towel with a decent bit of force to remove the spackles of paint over nearly a third of my engine mount. That didn’t leave it feeling the smoothest, but at least the speckles were nearly completely gone. Apparently a glob of paint or something got caught in the sprayer head…. which I cleared out. And a number of test sprays in the air to be certain, I continued on painting the engine mount.

As I waited the requisite 15 minutes for the fast drying paint on the engine mount to dry, I then preheated my kitchen oven to 175° F. I then popped the fairly dry engine mount into the oven and baked it for 30 minutes. My goal here on the engine mount paint is of course to have as nice as paint as possible in a reasonable amount of time, but, moreover, I want the engine mount protected against corrosion and for it to be visually inspectable for cracks (thus why no powder coating).

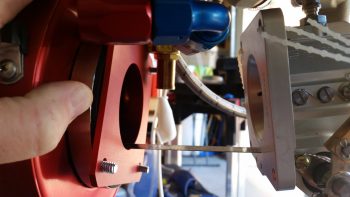

As the painted engine mount baked upstairs, I got to work on the engine mounted mechanical fuel pump. I took some BEFORE pics from both the right and left sides…

I then mounted the OUT side fitting on the fuel pump, which is a 90° steel fitting that also includes a 1/8″ NPT port straight out for installing a 45° reducer fitting for the fuel pressure sensor line (on the left in pics below). I also mocked up an AN6 90° hose end fitting (blue & red) to test out the angle for how the fuel feed to the fuel injection servo would run, and an AN4 90° hose end fitting (silver & red) for the fuel pressure sensor hose. The aluminum AN6 hose end fitting is just to test the angle. After I verified the angle was the best possible solution I pulled the trigger on a steel AN6 90° hose end fitting from Summit Racing (as well as a 90° 1/8″ NPT to AN3-3/16″ MAP port fitting).

I then installed the fuel pump fuel line feed IN fitting on the right side (as oriented in right pic below).

After getting the fuel line fittings squared away, and turning off the stove to let the just-baked engine mount cool, I took off for a bit to run some errands, grab some lunch, and pick up some 1/8″ thick steel angle from Home Depot for the engine mount mount that I’ll weld up for the engine stand.

Upon returning home I then grabbed the cooled and cured engine mount and proceeded to remount it back onto the engine. [A point of note: the paint on the engine mount is about a 1 meter paint job…. it looks great unless you actually get fairly close or touch it…. if it were an external component I would probably wet sand it and hit it with one more layer of paint, or clear coat even. Obviously it will be subject to high heat, oil, dust, dirt, etc. in the engine compartment, so I’m more concerned about a robust paint job vs. a sexy one.]

After I got the engine mount remounted to the engine, I then installed the last of the fuel pump’s fittings: the overboard vent line fitting.

Yet another shot of the fuel pump fittings.

After my airplane building credentials were called into question by a yet to be named Aussie (ok, I give . . . it was Dave Berenholtz!) Ha! I had to prove my mechanical prowess by actually getting the amazingly challenging cotter pins installed on the engine mount castle nuts. Seems like it shouldn’t be that difficult, but the angles and clearances are just killer! (All in fun my friend!).

Here are the top side cotter pins installed in the engine mount bolts and castle nuts.

And the bottom left cotter pin installed. I still have no intentions of trying to do this under cylinder #4 and will swap out that castle nut with a lock nut a bit later.

With the engine mount re-mounted on the engine and everything torqued to specs, there was nothing left to do but mount the engine! It was go time!

So here she is . . . engine is mounted!!!

I only had minor issues with getting the last 2 bottom horizontal bolts in place on the engine mount, but after a few minutes of finagling and some light tapping they went right in.

As you can see, even with the eventual fiberfrax and aluminum sheet firewall covering, the clearances are pretty good (by Long-EZ standards) with the firewall. The only clearance concern I have is between the fuel pump overboard vent fitting and the left aileron control tube…. I’ll have to watch that closely.

The engine looked a bit small and compact mounted to what I have so far of the fuselage, so wanted to see the cross-section of the engine…. here’s a taste of what that looks like:

•••

12 April 2018 — Today was all about getting as much of a jump as possible on the firewall configuration to get that stuff knocked out early.

After reviewing some info on installing NPT fittings I felt I should do my due diligence and check the torque on the 45° AN6 fitting exiting the FT-60 Red Cube fuel flow meter. It was tight, but I thought it could be tighter. However, if you’ve seen the install manual there is explicit warnings not to over tighten a fitting on account the transducer’s case might actually crack. In the AFP-30 Air Data Computer install manual there’s some literature on the FT-60 that states to torque the fittings to 25 ft-lbs. Since I had a box wrench adapter on a short extension mounted to my torque wrench, I dialed the torque down to 23.5 ft-lbs to ensure I didn’t crack the FT-60 case. Surprisingly, I was able to get one more entire revolution out of the 45° AN6 fitting… with how much pressure I had to exert to get to that 23.5 ft-lbs (again, remember I was using an protruding box wrench adapter on a short extension… both serving to add a mechanical torque advantage), I’m surprised people go further than that to crack these darn things!

Once I got the aft fitting on the FT-60 squared away, I then did some minor tweaking of the fuel filter and lines to get the filter flat again the front face of the firewall. I then marked the position of the Adel clamp hole and the fuel line exit point on the firewall. From inside the hell hole I drilled small holes out using my right angle drill. I then drilled from the aft firewall side coming back into the hell hole. You can see the drill bit in the pic below peaking through the firewall and aligned with the fuel line fitting.

Here’s a shot from the firewall side of my initial 2 holes through the firewall for mounting hell hole and firewall assemblies and pass-thrus.

I then took a #10 screw and Dremelled the head of it to create indentions for flox to better grip it.

After drilling out the fuel filter clamp screw hole and then counter sinking the hole, I then floxed the fuel filter Adel clamp mounting screw into place in the hole. After it cures I’ll layup a small ply of glass over it.

I then took a fair amount of time to figure out exactly where to place the Electroair electronic ignition coil unit on the upper firewall. I marked off a 1″ Demarcation Zone around the edge of the firewall to ensure I had space for both laying up the fillet glass to the upper cowling mounting overhang, plus room enough to run 1/4″ fuel vent lines as well. I also needed to stay as far left as possible to give myself room to get the oil filter out for oil changes.

I even called Electroair and conferred with Denny on the location and orientation of the coil unit. I played around with placing it just aft of where the CS Spar crosses in front of the firewall in the midpoint area of the firewall, and while there’s enough space in that area the spark plug wires would have funky runs to get to the spark plugs. So, in the end I decided it had to go on the upper firewall, but at an angle. It sits about 1/4″ above the SD-8 alternator and does very slightly impinge on the Demarcation Zone.

Here’s a closer shot of the mounting location of the Electroair EI coil pack.

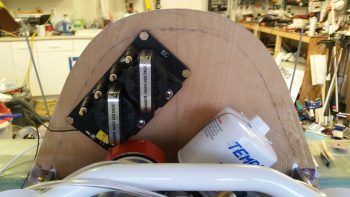

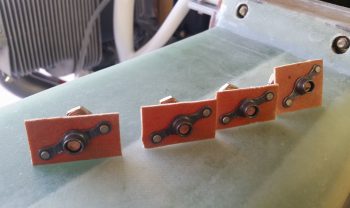

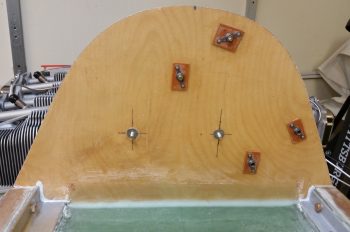

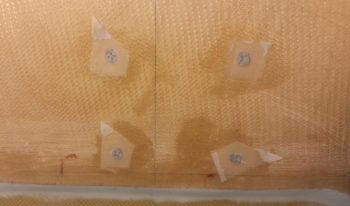

I then got busy making four K1000-4 nutplate assemblies for the AN4 bolts that would be used in mounting the Electroair EI coil pack. I cut and sanded the phenolic pieces and then riveted the nutplates to the front side of the assemblies.

Here’s an aft view of the Electroair EI coil pack K1000-4 nutplate assemblies.

Using the coil pack as a template to keep the AN4 bolts in their exact mounting configuration, I then floxed the 4 nutplate assemblies to the front of the upper firewall.

I then focused on installing the B&C Firewall/Engine ground stud and forest of tabs inside the hell hole [the usual configuration for the firewall/engine ground stud and forest of tabs is to have a forest of tabs on each side of the firewall. However, since I only have two items that require ground on the hot side of the firewall, I forewent installing the forest of tabs on the aft side of the firewall]. Although I didn’t get a pic of it, the engine ground strap is temporarily secured on the engine side where I plan to mount it permanently, so the length I ordered for the braided engine ground strap is spot on.

On the hell hole side of the forest of tabs, I then installed the big yellow ground cable that runs the length of the firewall to the negative ground post on the battery.

I then spent the next hour or so drilling and mounting the big yellow power cable that runs from the starter contactor in the nose battery compartment to the starter through a stainless steel firewall pass-thru. Inboard of the starter cable, I then drilled and mounted a Blue Sea connector for the Alternator’s B-lead that also heads up to the nose battery compartment.

Although this pic is a bit fuzzy, here is a final view of the firewall configuration tasks that I completed today. From the upper left hand corner you can see a hole drilled for the Oil Heat oil return line to the engine oil sump. Slightly lower and to the right of that is the main fuel line that feeds the engine driven fuel pump. Towards the middle is the #10 (3/16″) screw that I floxed into the hell hole as a mounting stud for the fuel filter’s Adel clamp. Then of course is the electrical firewall pass-thru package, starting from the left with the Blue Sea fitting for the Alternator’s B-Lead, a stainless steel firewall pass-thru with the starter power cable running through it, and then the engine grounding strap that connects to the the firewall ground stud that is opposite the forest of tabs inside the hell hole.

In the pic below I added in the Alternator’s B-Lead which will be paired together with the big yellow starter cable as they both exit the engine compartment via the firewall.

Here’s a wide-angle shot of the major engine component electronics, with the big yellow power cable of the starter, the Alternator’s white B-Lead, and the connected engine grounding strap connected to the firewall ground bolt.

Here’s bit closer shot of the starter and alternator power leads. Note that the Alternator’s B-Lead is terminated on the Alternator side but not yet at the Blue Sea firewall pass-thru. Also note that the starter lead cable is not terminated yet, and won’t be until I get the Fiberfrax and 6061 aluminum sheet affixed to the firewall.

Here’s the hell hole view of all my firewall-based shenanigans. Note that the fuel filter mounting screw is visible in-between the 2 yellow zip ties.

Here’s a little broader view specifically showing the Adel clamp that secures the pair of big yellow power cables.

•••

13 April 2018 — I started off this morning inventorying a much-needed order from ACS that I just received. Included in the order was -20 sized Adel clamp for the fuel filter, that I immediately pressed into service. I cleaned the fuel lines fore and aft of the fuel filter then mounted them “permanently” (albeit servicing will occur…yes) to the filter, as well as permanently mounted the origin of the incoming line of the fuel filter (on left in pic below) at the FT-60 Red Cube fuel flow transducer.

I also received the 45° -6 AN bulkhead pass-thru for the fuel line and a 45° -8 AN bulkhead pass-thru for the oil heat return line. I finished drilling out those pass-thru holes to size and mounted the fittings through the firewall. As you can see I then mounted the fuel line and the oil heat return line to the 2 new firewall pass-thru fittings. To be clear, these pass-thru connections are NOT permanent installs at this point since they’ll need to be removed when the Fiberfrax and 6061 aluminum sheet cover get mounted to the firewall face.

Here’s a firewall shot of the 45° -8 AN pass-thru for the oil heat return line and the 45° -6 AN fuel line bulkhead pass-thru.

I then gathered up all the accouterments that I needed to make up some engine compartment stainless steel braided hoses with hose ends. Here’s the first hose I made, which is a -8 hose for the oil heat oil return line.

I then made up a -6 hose for the main fuel line feed to the fuel pump. One thing I honestly didn’t count on mentally was how SHORT these hoses would turn out based on the confined space of the engine compartment. I mean, really, the actual length of the hose component of the oil heat oil return line is only 3.7″ long! Crazy!

Since I had all the stuff out to make hoses I went ahead and terminated some ends ahead of time, like this hose end for the fuel pressure sensor line with the 90° hose end fitting on it. I was going to do the fuel pump side hose end on the fuel line that goes to the fuel injection servo, but realized I had a head space/timing issue (Browning 0.50 cal reference there) when I ordered the fitting and apparently the fine print said for PTFE hoses only…. oops and dammit! Ok, another hose end fitting order coming up!

I also attached a hose end fitting to the -8 oil line hose stock and –unrelated– installed the upper fuel spider hose end fitting to the -4 hose that will go from the fuel injection servo to the fuel spider.

Here you can see the hose peeking out the bottom of the engine. I’ll of course cut this hose to length and terminate it with a -4 AN hose end fitting once the fuel injection servo is set in its final configuration.

I know the bottom shot is a little blurry, but it’s a decent view of the 2 hoses I just made up today.

And another one from below the engine, at the bottom of the firewall.

I also worked for a couple of hours in assessing the bottom engine area, to include the location of the oil heat sump feed line, the oil drain valve, the fuel injection servo, air intake elbows, and the RAM air intake. Believe me, there was a lot of musical chairs going on in setting up the configuration (read: major configuration changes) to even begin to work. I even had to pull out the lower cowling and mock install it a number of times to check for clearances. Not surprisingly, there is just so LITTLE space for everything to get crammed in there, and I had to resort to a myriad of small, constant changes to even being to get close to the configuration I want.

One immediate change (that I was allowing for) that happened after ascertaining the amount of clearance between the lower cowling and the cold air intake tubes is that I moved the alternator and starter power wires to traverse the engine heading forward on the inboard side of the cold air intake tubes vs the outboard/lower side.

•••

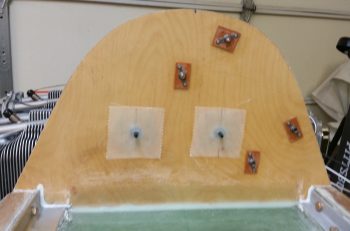

16 April 2018 — I wanted to get some glass curing overnight after I got home from a 2-day trip to Marco’s, so I spent a good half hour figuring out the best spacing and mounting for the 2 MAP sensor boxes… one for the GRT EIS and the other for the Electroair EI.

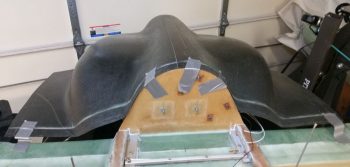

Originally I had planned on mounting them both vertically, but when I assessed the internal configuration and best spacing within the GIB headrest/D-Deck area, I decided to place them both mounted horizontally, as the GRT MAP sensor is below (with the Clickbonds 5 min glued in place). The Electroair EI MAP sensor box will get mounted directly below the GRT MAP sensor box.

After letting the 5-min glue cure about 10 minutes, I then removed the GRT MAP sensor box. I cleaned up the excess 5 min glue and sanded around each of the Clickbonds.

I then laid up 2-plies of BID over each Clickbond, peel plied them both, and then left them alone to cure.

•••

17 April 2018 — I started off today by making a decision on my electrical system, one that had been nagging me a bit in the back of my mind. The impetus for me making this decision today was a response by Bob Nuckolls on the Aeroelectric Connection forum that brought it all home for me. In a discussion on something else related to protecting wires with fuses and circuit breakers, Bob noted: “Recall that circuit protection is for WIRES . . . and that the protective device is installed as close as practical to the SOURCE of energy that puts the wire at risk.”

Thus, my ANL-40 fuse link is going back on the firewall, on the hell hole side. I’ll most likely use a piece of 1/8″ thick x 1/2″ wide copper to connect the forward (hell hole) stud of the Blue Sea terminal to one side of the ANL-40, then run the B-lead from the ANL-40 forward to the battery contactor (however, I’m leaving the option open to use 8 AWG cable and use this connection as the location for the GRT EIS Hall Effect sensor). This configuration will add a hair more weight aft, but puts better protection on the source of the B-Lead and cleans up my busy nose battery compartment a bit.

I didn’t mention conversations I had yesterday with both Rod Bower (RAM air unit) and Precision Airmotive (Silver Hawk fuel injection) as Marco and I were convoying in our separate trucks to his hangar. I asked the Silver Hawk guys if I could attempt to thread the -4 AN fitting on the top of the fuel injection servo as far as it would go into the unit in order to attain as much clearance as possible with the bottom of the cold air induction plenum situated just above the fitting. They said this would be no problem and that I wouldn’t damage anything internally/inside the fuel injection servo.

I queried Rod on some specifics about moving my RAM air box forward and mounting it directly to the aft side of the firewall, but he couldn’t picture it mentally and I ended up sending him the pic below much later after I arrived back home.

Rod got back to me today and we discussed mounting his RAM air unit with the nose of it sticking into the firewall, with about a 5.5″ gap between it and the front face of the fuel injection servo intake plate. The requirement for this gap between the RAM air canister –which would normally mount to the front of the fuel injection servo– is twofold: 1) The RAM air canister is too wide at the aft side of it (note that it’s shaped somewhat like an Apollo capsule) and would interfere with the bottom cowling. 2) There would be no clearance for neither the oil drain valve (brass valve in pic below) nor the forward-placed sniffle valve.

To allow for enough clearance with the aft end of the RAM air canister with both the oil sump above it and the lower cowling below, I determined that it must be mounted in the clear space just forward of the oil sump. This spot will allow the RAM air canister to be mounted an inch or so higher and still clear all the top side oil sump/cold air induction plenum and the lower cowling below . . . barely!

[In the pic below you can see the location of my initial planned hole for a 3″ bracket (shown bottom left corner), then a piece of 3″ SCEET tubing, then the RAM air canister mounted to front face of the fuel injection servo. Clearly, the reality of limited space and conflicting requirements for use of that space significantly changed the configuration of my air induction system. Currently the plan is to install the nose of the RAM air canister approximately 1″ higher than the circle depicted on the firewall below].

After some discussion Rod was able to see what I was talking about and signed off on the plan. In response to my question, he stated that he saw no ill affects in his assessment of my running a 2.5″ piece of SCEET tubing from the aft side of the RAM air canister to the front intake of the fuel injection servo (note smaller diameter than that previously planned 3″ SCEET tubing preceding the RAM air canister).

After getting Rod’s sign-off on the new air induction configuration, I then got busy mounting the Electroair MAP sensor unit on the front face of the firewall in what will be the GIB headrest/D-Deck component housing.

I marked the holes and here you can see the top 2 holes are drilled.

I then had to make some minor adjustments for hole alignment as I drilled the remaining 2 holes.

I then test fitted the MAP sensor, but will hold off on the actual screw install since I don’t have good access with the engine installed to the aft side of the firewall (the screws will get floxed in from the aft side of the firewall to the front side to create 4 screw posts… analogous to click bonds).

And another shot of the final placement of the GRT and Electroair MAP sensor units.

•••

18 April 2018 — I actually spent quite a few hours today building a lower cowling dolly that you’ll see in a number of the pics below. I saw one of these in fellow Canardian’s hangar (who had sadly gone west) as we were helping remove the wings off of his Long-EZ and thought it was a good idea. Well, although I got the dimensions from Marco, they didn’t translate over for whatever reason to my cowling and build dimensions (possibly since my fuselage isn’t loaded all the way down?).

My goal today was to mock up the lower cowling in its close to final position (as best possible) to check the clearance between it and the engine air induction system… specifically the fuel injection servo. To better ascertain the position of the lower cowling, I went ahead and set the top cowling in place, which I was going to do in short order anyway.

I then used duck tape to help wrangle the 2 cowling halves into some semblance of order. I’m definitely happy with the fit of the cowlings, and although Mike Melvill had an IO-360 inside of them, trust me, they are still a close fit to an IO-320 sized engine.

I taped the cowling at the top cowling-firewall interface, and was glad to confirm I have a good firewall fit, with the shape of it matching the cowling shape.

Since I had the top cowling close to its final position (I double-checked the plans, my notes, other builders’, etc. to ensure I had it close to where it needed to be…) I then made some templates to use for the cowling angle interface with the canopy and D-deck/ turtledeck assembly.

Here’s another view of my canopy-top cowling interface angle template. Clearly there may need to be a curve thrown into the mix as I mount the canopy, but it gave me a good starting point.

I also drew hash lines on the longerons and marked the extended angle of the top cowling contour about 18″ forward of the firewall.

Here was my version of the lower cowling dolly. Mine needed to be much wider front to back and much taller than the one that Walter built for his airplane.

As you can see, I removed the top cowling to better check the clearance between the bottom cowling floor and the fuel injection servo.

Here was the best shot I could get of the fuel injection servo position inside the lower cowling. It may be hard to tell, but in this configuration there was NO clearance and the cowling is actually just touching the fuel injection servo. In fact, the very bottom nub sticking out to the right on the servo is the main fuel feed line attach fitting… clearly no room even to connect the fuel feed hose!

Very frustrated and perplexed on my no-clearance issue with my lower cowling, I took a break and grabbed something to eat. After about an hour, with the worst case scenario of having to extend a trough under the lower cowling in my mind, I went back down to the shop to assess the clearance issue.

As I was literally sitting under the engine just looking at the layout, I came up with a very viable solution.

You see, my paradigm was that the main fuel line was coming in from the right side, and the hose coming in from the fuel distribution spider on the top of the engine was from the left. There was no need to change any of that, but I did need to rethink the one thing that was really causing my clearance issues: the -4 AN 90° fitting on the top of the fuel injection servo. I had it pointed to the left as I lamented the lack of clearance between it and the bottom of the oil sump . . .

But if I moved the servo about 1/2″ forward (which I could do since I had spacers installed in between the elbows), not only did it push it forward to where the cowling was lower, but if I faced the top fitting to the RIGHT then it put the fitting right into a V-shaped channel on the bottom of the Superior cold air induction oil sump. This allowed clearance to get the hose end fitting onto the servo outlet fitting! Yes, I would have to spend another $20+ on yet another hose end fitting, but by doing this configuration change it gave me 2 options: A) Run the fuel distro spider hose above the fuel injection servo and in front of the air duct elbows with a 150° U-turn hose end fitting, or B) Run the fuel distro spider hose aft of the air duct elbows with a 90° hose end fitting (I’ll admit that to acquire the best solution here I bought both fittings…).

The resulting change in my configuration required only about a 3/16″ phenolic spacer between the lower 85° elbow and the fuel injection servo. It did mandate a requirement to replace the threaded studs on the cold air induction plenum for connecting the upper elbow to the plenum (at a minimum the lower studs, since it is virtually impossible to get a nut with so many washers on them with the current configuration).

In figuring out the final install point and configuration of the RAM air canister (not pictured here) I needed to install the 1/2″ NPT elbow on the bottom of the oil sump to assess how to route the hose from the sump to the firewall…. around the RAM air canister. I tested a 90° hose end elbow (blue & red) but think a straight hose end may work as well. However, since the oil heat feed line from the sump looked like it would enter the firewall on the lower left side, this required the associated hell hole oil line to crossover from the right side oil pump fitting over to the lower forward left side of the firewall (again, crossover in the hell hole). Not a big deal, but I would have to avoid it and go above the RAM air intake expansion chamber ( . . . never-ending ripple affects!).

The bottom line is that it looked like all the components should fit, but the clearances from one component to the next were all AMAZINGLY CLOSE (but would note not too close to allow vibration to cause issues).

Here’s the oil drain valve with the oil heat feed 90° fitting just behind it (pic from right side of engine).

I was fairly confident that this configuration would give me just enough of the clearance I need below the fuel injection servo and allow for all the critical air induction and underside oil sump fittings to play nicely with each other.

Of course I had to also rotate both the fuel injection servo’s throttle and mixture levers to avoid hitting the lower cowling (I had already planned out these mods), but again, I didn’t foresee any issues with those as well.

•••

20 April 2018 — Today, after a fair amount more research, I got down to the shop and pulled the trigger on drilling the 3-1/8″ hole in my firewall for the nose flange of the RAM air canister to fit into. As you can see by the original marks on the firewall, my new location is significantly higher on the firewall than where I had planned to place it originally.

I then test-fitted the RAM air canister and as I’ve mentioned many previous times, it did just fit . . . barely. But it fit!!

Here we have the RAM air canister peeking through the firewall from the Hell Hole side.

And even though the RAM air canister was tilted down a bit on the aft end –since I wasn’t holding it in place– you can see the position of the aft air exit hole and how a piece of tubing from the RAM air box to the fuel injection servo would be clear of any entanglements from above such as the oil drain valve and the oil heat feed fitting.

Since I moved the fuel injection servo forward to position the top 90° outlet fitting into a “V” groove on the bottom side of the Superior cold air induction plenum for clearance, that reduced the distance between the aft face of the RAM air canister to the front face of the fuel injection servo from 5.5″ down to only 3.7″. Still enough to allow flexing between the firewall-mounted RAM air canister and the engine-mounted fuel injection servo.

Also note in the pic below that the tubing in-between the 2 units will need to curve upward at the aft end about 1/4″ due to the position and angle of the fuel injection servo. I don’t see this as being an issue since I will be using flexible SCEET tubing.

Here’s a wider angle shot showing a close view of how the units will look in their final installed configuration.

I then spent a good 30 minutes dialing in the location of the firewall mounted MAP sensor/ fuel pressure sensor/oil pressure sensor manifold block. I pretty much got its mounting spot located.

•••

21 April 2018 — Today the FedEx guy delivered my last (hopefully) round of fittings that I ordered from Summit Racing. Again, my first choice for connecting the hose coming down from the fuel distribution spider atop the engine to the -4 AN 90° fitting on top of the fuel injection servo was the 150° hose end fitting. And as I mentioned before, my backup was a 90° hose end fitting if the 150° hose end didn’t work out.

Quite nicely, however, the 150° hose end fitting worked like a champ!

For this fuel line, I also employed and test fitted an Adel clamp secured by the front left corner bolt where the induction air intake elbows mate together. I think this Adel clamp position will work nicely to secure the -4 hose going to the fuel distribution spider from the top-mounted fitting on the fuel injection servo.

Here’s a bit closer view of the -4 fuel line feed to the fuel distribution spider from the fuel injection servo.

I then took a while to figure out and dial in the position and angle of my oil sump oil heat feed line that exits out of the bottom of the oil sump via a 90° steel fitting (that I calculated a 4.4″ tall standpipe will get welded to) to a firewall pass-thru fitting. I had some angled hose end fittings on hand, but decided that to keep a nice constant curve around the RAM air box that I’d use straight hose end fittings.

I then spent a couple of hours assessing and dialing-in the flow and Adel clamp attach point for the final piece of hosing to complete the fuel line from the fuel intakes in the main strake-located fuel tanks to the cylinder fuel injector nozzles: the -6 hose from the fuel pump to the fuel injection servo.

At the fuel pump side I actually entertained the idea of cutting part of the flat flange insert at the corner of the engine mount in order to have the fuel pump out hose end fitting face outboard of the engine mount tube. But, laying below the engine looking straight up at it, I realized that more of the hose end fitting was showing on the inboard side than the outboard side, meaning that I could get a more down angle of the hose end fitting by leaving it inboard. So, no drilling or cutting of the engine mount flange took place.

On the fuel injection servo side, I had planned on actually running the hose aft and looping it in from the aft side to arrive at the fuel injection inlet fitting at a 0-45° angle. But then after looking at and assessing the travel of the mixture lever on the fuel injection servo, I decided to simply bring the fuel line down from the top from a slight forward-to-aft angle.

So here it is: the final fuel line piece for this entire aircraft. Yes, of course the fuel VENT lines will still need to be run, but this does it for the actual fuel lines.

•••

22 April 2018 — Today I did about 2 hours worth of spring cleaning in the shop to get it a little squared away for all the upcoming activity.

I then set my sights on mounting the 8″ prop extension to the flywheel and the engine prop flange. It took about a half hour, a block of wood and a bunch of medium strength taps with a rubber mallet to get that sucker seated to within about 0.1″ of the flywheel. Then I very gently tightened all the bolts to get the prop extension to seat tightly against the flywheel.

Then, as per Sam’s (from Saber Manufacturing) directions, I torqued the 6 prop extension, prop flange and flywheel bolts to 50 ft-lbs each.

I then safety wired the bolts in pairs using 0.041″ stainless steel safety wire.

This is my first go at safety wiring, so if anybody out there sees anything disagreeable, please give me a shout. I’m always open to constructive criticism. Of course, I’ll have my EAA chapter bubbas look at the build as well.

Here’s the final shot of the installed prop extension. Let me tell ya, the only time this thing is getting removed is when the alternator belt needs replaced! [Since I planned on test mounting the prop and of course taking some pics I figured I would get the prop extension install out of the way].

It was getting later in the evening, so I decided to relax and watch some TV while I played with my new toy: a ClampTite tool. I removed and brought the fuel line and oil heat oil line with me upstairs.

Then, using the Clamptite tool (another first for me), I fire sleeved the 2 hoses. Note that I’m using blue fire sleeve for fuel lines and black fire sleeve for oil.

As I’ve seen on Joe Caraggio’s site and others, there seems to be a requirement out there (or at least a good idea) to seal up the ends of the fire sleeve so the wool-type lining doesn’t soak up any stray oil, fuel, or what have you. I had some of the expensive gray 3M fire barrier on hand so I decided to seal up the ends with that.

Here I’ve applied the 3M Fire Barrier to the ends of each fire sleeved hose….

However, I’m not a big fan of how the gritty, blotchy gray Hi-Temp RTV ends looked, so I cut a narrow piece of heat shrink and covered the RTV’d ends up…ahh, much better!

My final build act of the evening was to simply reinstall the hoses back onto the engine. I definitely think the fire sleeving will work and I’m glad I went this route.

•••

23 April 2018 — I started today off by spending well over 2 hours doing some much-needed spring cleaning on the shop.

I then temp-mounted the propellor with the crush plate just for picture day. I was pleased with the how prop fit and looked mounted on the back end.

I took a slew of pics of course. I ended up posting shots of the fuselage at different angles. Believe me, I chucked a ton of pics out! The main shot I was after was a straight shot from the aft end with the prop and wheel pants installed.

Here’s an angled aft view.

With these pics captured, my main goal is to weld up the angle-iron mounts that will allow the engine-on-mount to get mounted to the engine stand.

Although very close to the one above, I included this shot since it’s positioned a bit nose higher.

Another shot from a high angle. In addition to the shots I took, my neighbor came over and set up all his photo shoot equipment and took a ton of pics with his high-end digital camera. When I get those pics I’ll most likely post them here on my blog.

I’ll note that I’m very pleased with the how the wheel pants install turned out.

Here we have a shot of the installed right wheel pant with the canopy mocked up in place.

•••

24 April 2018 — I started off today by removing the prop, getting it packed back up and put away . . . without incident.

It was later in the evening and I decided to get something else done on the build, and since it was too late to do all the grinding and metal cutting that I needed to do for the engine stand mounting brackets, I pulled off the -4 stainless steel braided fuel hose that runs from the fuel injection servo that’s mounted on the bottom of the engine to the fuel injection fuel distribution spider on the top of the engine. I then took it upstairs and fire sleeved it.

As most of you are (painfully) aware, my phone camera is just not that good at capturing pics, and since I just couldn’t get both ends of the entire hose in focus….

. . . I took separate pics of each end of the hose.

I have to say that the first couple of hoses I fire sleeved I used up the stainless steel wire that came in the package with the ClampTite tool. Little did I know at the time that they included 0.041″ stainless steel wire with the tool, because when I used 0.032″ wire on this hose . . . wow, it understandably went from quite the struggle to a fairly EZ endeavor wiring up the fire sleeve on this hose. Yes, the ClampTite tool is infinitely more enjoyable to work with when using smaller gage wire!

After sealing the bare hose end edges with gray 3M fire barrier Silicone RTV and covering that application with a strip of black heat shrink, I then reinstalled the hose on the engine. So here we have the freshly fire sleeved -4 hose connected to the fuel distribution spider atop the engine.

And here is the lower side of the fire sleeved -4 hose connected to the 90° outlet fitting on the top of the fuel injection servo. Since I marred the Adel Clamp drilling its mounting hole out to 5/16″ diameter the last time, I’ll make up a fresh one it comes time to do the final install of the hose.

And one more shot of the newly fire sleeved fuel distribution outlet hose coming from the top of the fuel injection servo.

•••

3 May 2018 — Today I whipped a small batch of epoxy with fast hardener and made up some wet flox. After I filed down the round countersunk heads of the Electroair screws into a triangular shape to give flat gripping edges, I then floxed them in from the aft side of the firewall into the D-Deck area for mounting the Electroair MAP sensor unit.

Here are the 4 stainless steel countersunk screws from the firewall side.

And here’s an even closer shot of the 4 stainless steel countersunk screws that will secure the Electroair MAP sensor in place. As you can see I peel plied them to ensure the firewall surface remains even and smooth.

A few hours later after the flox had cured I pulled the peel ply from over each screw.

Here we have the 4 Electroair MAP sensor mounting screws floxed in place from the aft firewall side.

Here we have the 4 Electroair MAP sensor mounting screws floxed in place from the aft firewall side.

And the Electroair MAP Sensor set in place on its 4 mounting screws.

And here are the two MAP sensors that will be in use on this airplane: the top-mounted GRT MAP sensor and bottom-mounted Electroair Electronic Ignition MAP sensor. As a point of note, the MAP line does actually run to the PMag in the engine compartment as well.

Today I also wanted to knock out the last couple of engine hoses that were available for fire sleeving… Again I sealed the bare fire sleeve ends with 3M fire barrier and then covered those sealed ends with narrow strips of black heat shrink. Top black hose is the oil heat oil return line back into the sump while the bottom blue hose is the fuel pump to fuel injection servo feed line.

•••

13 May 2018 — Today, when I started clearing off my welding table, I ran across my stainless steel upper left firewall pass-thru. I needed to trim it up and instead of setting it aside to do later and forgetting about it –like I did last time– I just spent the 20 minutes [and 3 Dremel disk changes…. that stainless steel is TOUGH!] to get it done.

Here’s a shot of what it looked like before, in case you didn’t remember.

I then mocked it up on the firewall for a quick test fit…. looks good and I think it will work fine.

•••