Today was all about “engineering” and design tradeoffs and task redo’s.

I started off with lopping off an angled piece of 3/4″ stainless steel tubing that will serve as the right exhaust pipe bracket’s pass-thru for the crankcase vent tube —that nestles into the top V-groove of the right exhaust pipe pair for about the aft 2/3rds of the overall exhaust pipes’ run. Since the pipes angle inboard the hole in the bracket plate needs to be less round (pic #1) and a bit more oval (pic #2).

After messing around with the right exhaust pipe bracket crankcase vent tube pass-thru for a bit, rewickering the CAD model and 3D-printing updated versions, I then took a break to go see my race car header welding buddy James to (re)weld up the left outboard exhaust pipe.

James did a phenomenal job as par usual, and below is the freshly rewelded left outboard exhaust pipe back home and in its place on the engine.

Now, that being said: my goal was to position the curved exhaust pipe insert (new piece) to get the outboard exhaust pipe “around the bend” in regard to doglegging it around the vertical slip tube portion of the inboard pipe, to then nestle in and align parallel with the inboard exhaust pipe on the back end. Unless tack welding these joints and course correcting in situ on the engine, it’s not unreasonable to expect a slight loss in translation when I position it by pressing and taping together in my shop, compared to it actually getting welded up on a bench 40 miles away.

On the left exhaust pipe pair I have a gap between the pipes that is present (no issue as per Klaus Savier… actually preferred!), and after its rewelding the outboard pipe’s curve is probably 0.15″ to 0.19″ (a few degrees) more than I had planned. This pushes the outboard pipe’s middle out away from the inboard pipe’s vertical slip tube portion a bit more when the very aft ends of the left pipes are kissing. Thus, to keep the gap line between them more parallel, I need to kick the inboard pipe even more inboard about 1/4″, perhaps even as much as 3/8″ by the end of the day.

Bear with me…. as I told my buddy Dave Berenholtz in an email recently, these pipes are simply not the right ones for my engine and cowlings. And with that being said, the final curve on the very aft end for all 4 pipes is at about the worst possible position, driving me to cut the pipes’ ends much deeper into the cowling (2-2.5″) than I prefer.

Or so I thought.

The slight unintended kick-out on the just rewelded outboard left exhaust pipe may be a blessing in disguise (in keeping with my motto: “better to be lucky than good!”) in that by bringing in the pipes as inboard as possible —”uncomfortably close” to the prop spinner lampshade— it then better aligns the outboard turning final pipe bend to shoot straighter out the back. Versus trying to cut off the majority of each aft/final bend and point the straighter pipes inboard. Roll with the flow and use your opponent’s natural energy against them.

The slight unintended kick-out on the just rewelded outboard left exhaust pipe may be a blessing in disguise (in keeping with my motto: “better to be lucky than good!”) in that by bringing in the pipes as inboard as possible —”uncomfortably close” to the prop spinner lampshade— it then better aligns the outboard turning final pipe bend to shoot straighter out the back. Versus trying to cut off the majority of each aft/final bend and point the straighter pipes inboard. Roll with the flow and use your opponent’s natural energy against them.

I looked back at my notes on when I was configuring the top and bottom cowlings in joining them together around the aft cowl opening. My distance from inboard edge of the left inboard pipe to prop spinner lampshade was 2″. That distance on the right was 2.5″. Currently I’m pushing those respective numbers inboard about 1/8″. Now, that measurement is not the opening exit point of those inboard exhaust pipes, but rather the closest point of the pipe that then curves back outboard with the exhaust exiting either parallel with aircraft centerline (at best), but in reality actually aimed a tad more outboards.

To capture and verify what I had assessed on the left side, I mounted the top cowling in place. I also wanted to look at the upward angle of all the pipes to see how close the exhaust would get to the actual aft lip of the upper cowling. Close, but no issue.

Now, the right exhaust pipes are not trimmed at all, so they appear much more outboard in pics than they really are. I’ll reiterate that without cutting and rewelding, the closest these pipes can come inboard is about 2.35″ away from the lamp shade. I however was still at 2.5″ away and since I’m bringing the left set of pipes further inboard (and trimming the ends to be about 1.5″ inside the cowling), I needed to bite the bullet and get the right side pipes as inboard as possible as well.

Which of course jacks up all the work I just did on the right side exhaust pipe brackets. Do it right! (right?!)

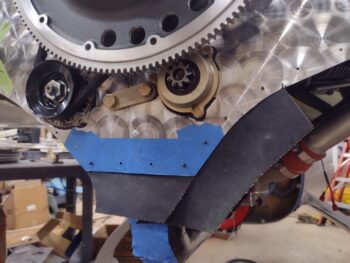

Using my known new gaps by driving the right pair of exhaust pipes further inboard by about 1/8″, I then redrew the bottom right exhaust pipe bracket onto cardboard. Not bad just out of the gate I have to say, and definitely good enough to import into CAD.

I then did the same thing on the top right exhaust pipe bracket. Again, not too bad at all.

I took my latest top and bottom cardboard mockups of the right side exhaust pipe brackets into the house and imported them both into Fusion 360 CAD and got the initial modeling of those knocked out. I 3D printed the top bracket mockup and did a quick fit test on it out in the shop.

It was very late in the evening by this point, and with corrective annotations in hand I took the top 3D printed mockup back into the house to tweak it further tomorrow.