Today I measured out and looked at different wiring & conduit options. I decided to go with Marc Zeitlin’s method (I guess I should have checked my notes before yesterday’s post!).

I have to apologize ahead of time because I swore I took pictures of today’s progress, but currently I can’t find them. I will keep looking though. So, on with the build log:

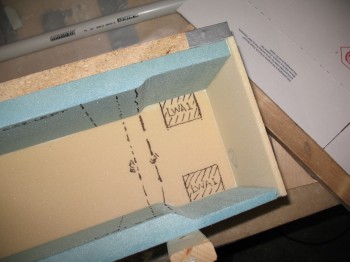

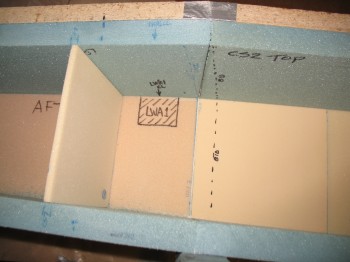

I cut a 1″ hole half-way through the foam of the end bulkheads from the inside of the spar box. I’ll cut a 7/8″ hole later on from the outside, going into & more closely matching the Inside Diameter of the 1″ tube on the inside of the bulkhead. As I said before, the 1″ tube will simply run from the outside bulkhead to the interior bulkhead to serve as a conduit to get all the wing electrical wires and antenna cables cleanly from the wing, into the CS spar to be routed from there throughout the fuselage. This will be on both sides of the CS spar, so one conduit on each side. The hole I cut (drilled) on each end bulkhead is just above the bottom aluminum extrusion to keep as close to the bottom of spar & shear web as possible, but still allow clearance for the wing bolt.

I then drilled holes in the aft bottom corner of both interior bulkheads, opposite the exterior bulkheads. I cut the ~1″ (technically 25mm) plastic tubing at a slight angle on each end to fit cleanly on both sides & into the recessed holes on the interior side of the Outboard bulkhead and the vice versa on the Inboard bulkhead.

I used a 3/16″ x 5″ scrap piece of blue foam to prop up the middle of the plastic tube–since it was suspended between each bulkhead–to cut on down on any possible vibration tendencies, rattling, etc. I used micro to attach the blue foam block to the interior back wall of the spar.

I then micro’d both ends of the plastic tube in place into each of the recessed holes on the bulkheads (one tube on each side of CS spar). I also micro’d the center of the tube to the blue foam block. I then glassed a 1-ply BID 4″ x 8″ layup over the pipe & blue foam block.

Ok… Although I am both a convert & believer of Burt, I guess sometimes I doubt a little if something is as strong as it is… even though it would probably far exceed my expectations. Thus was the case with attaching the front foam pieces to the rest of the spar box (remember, this is the “top” as it sits in the jig). I measured out where the interior bulkheads would abut the interior front spar face, marked it and sanded it down for a future 1-ply BID corner tape just for a little reinforcement (mod… not per plans). Not that I was doubting Burt in his design, I was merely “helping” him out . . . haha!

I then (per plans) prepped the front spar pieces for attachment to the rest of the spar box. I removed more peel ply boogers & sanded down some areas need extra attention.

I removed the front wood jig supports, thoroughly vacuumed the inside of the spar box, and wiped down the front (soon-to-be-mounted) spar wall pieces.

I taped the edges of any foam that would subject to any type of micro slop & mess. I then micro’d, nailed and weighed down the front (yellow foam) spar wall pieces (top as far as the jig is set) to the rest of the spar box.

Clock start time for my “2-3 day cure time” was 0100 Saturday morning.

I checked the micro’d pieces ~2 hours later & put some more nails to hold some areas better into place & aligned. I also removed a bunch of tape & gummy micro.

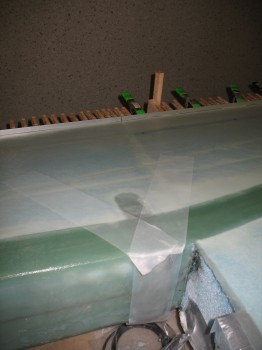

I took the wing outside & placed on the fold out work table, and then sanded all the bondo off the wing.

I took the wing outside & placed on the fold out work table, and then sanded all the bondo off the wing. After I finished sanding the bondo off the wing & then cleaned off the wing (the rain helped with that!). I then stored the wing in my environmentally controlled storage facility (ha! yes, my dining room . . .)

After I finished sanding the bondo off the wing & then cleaned off the wing (the rain helped with that!). I then stored the wing in my environmentally controlled storage facility (ha! yes, my dining room . . .) Now, let me talk a little bit about some housekeeping items. Literally. Of course in the pic above, it’s a bit messy. Well, since I’m on quite the accelerated schedule–to be able to use all the epoxy I bought en mass–I had to choose between glassin’ & sandin’ versus keeping everything else ship-shape. Essentially, it comes down to my prioritizing the build over pretty much everything else for a few months.

Now, let me talk a little bit about some housekeeping items. Literally. Of course in the pic above, it’s a bit messy. Well, since I’m on quite the accelerated schedule–to be able to use all the epoxy I bought en mass–I had to choose between glassin’ & sandin’ versus keeping everything else ship-shape. Essentially, it comes down to my prioritizing the build over pretty much everything else for a few months.

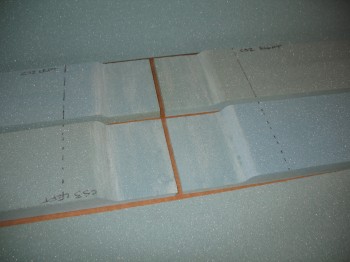

Since foam gets micro’d on the surface of the shelf… and we prefer NOT to leave any foam chunks of our CS spar left attached to the wood, I covered the entire shelf assembly with duct tape (maybe the differences in wood types was getting to me a little as well).

Since foam gets micro’d on the surface of the shelf… and we prefer NOT to leave any foam chunks of our CS spar left attached to the wood, I covered the entire shelf assembly with duct tape (maybe the differences in wood types was getting to me a little as well).

I then took inventory of the foam & ensured it was in good shape/undamaged.

I then took inventory of the foam & ensured it was in good shape/undamaged.

You’ll notice (if you’re a builder) that I’m using the slightly denser 3# blue PVC foam vs the 2# polyurethane. Both are fuel resistant, unlike wing foam which dissolves rapidly in fuel & other hydrocarbon-type liquids. Polyurethane is much easier to shape, but the dust is horrible and the chance of delaminations are much higher on the polyurethane. I generally use wood working tools on the foam anyway, so the blue should be ok to work with.

You’ll notice (if you’re a builder) that I’m using the slightly denser 3# blue PVC foam vs the 2# polyurethane. Both are fuel resistant, unlike wing foam which dissolves rapidly in fuel & other hydrocarbon-type liquids. Polyurethane is much easier to shape, but the dust is horrible and the chance of delaminations are much higher on the polyurethane. I generally use wood working tools on the foam anyway, so the blue should be ok to work with.

I then stood the wing assembly back up & made some final preps for glassing the BL 55.5 rib tomorrow.

I then stood the wing assembly back up & made some final preps for glassing the BL 55.5 rib tomorrow.