Well, I finally finished removing the peel ply from the TE. I then finished cleaning it up.

I sanded most of the Inboard spar cap area, including around the aluminum wing bolt extrusions. Specifically, there’s a 1″ strip of glass between the Outboard extrusion & the side of the front of wing jut-out (BL 55.5) that was pretty rough & needed some tough love. I sanded it down & got it fairly smoothed out in that 1″ strip. It needs to be smooth since the rib that gets glassed into the front of wing BL 55.5 jut-out will overlap onto this surface. I also cleaned up the aluminum extrusion faces & the wing bolt access overhang piece (W18).

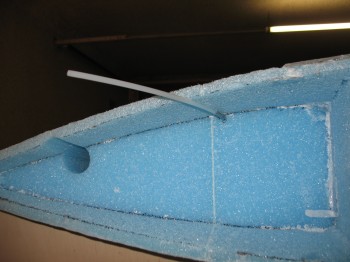

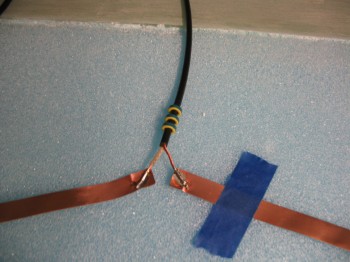

I installed the NAV2 VOR antenna by running the cable into the foam & down into the wing wiring channel.

Again, I formed & taped an extension for the BL 55.5 front of wing jut-out (where the blue tape strip is in the pic above) to be installed and will allow the glass to overhang straight. (both of my Inboard FC4 pieces were rounded over just a bit for about 4″, so I just want to the glass to come straight out and not follow the roundover… which is only about .1-.2″ deep)

Again, I formed & taped an extension for the BL 55.5 front of wing jut-out (where the blue tape strip is in the pic above) to be installed and will allow the glass to overhang straight. (both of my Inboard FC4 pieces were rounded over just a bit for about 4″, so I just want to the glass to come straight out and not follow the roundover… which is only about .1-.2″ deep)

I tacked on the 1″ x 65″ peel ply at the aileron junction (again, on the wing side).

The final large UNI layup on the wing is 1 ply of UNI that goes from the Inboard side straight out to the tip of the wing. This starts above the aileron & follows the top edge of the aileron at the aft side of this layup. So, I marked a spot at 5.9″ from the TE at BL 55.5 & put a spot at 4.35″ up from the TE at BL 106.25 to mark the aft UNI edge of this layup. Now, there are a few other smaller layups that get glassed, but this is the last really big one.