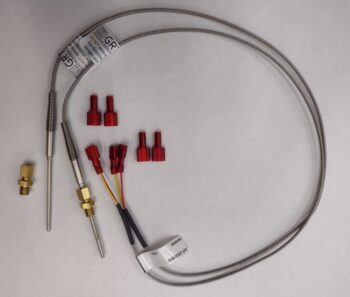

To start off with, I’ll note that I don’t like bashing smaller companies who are putting out products for the experimental aircraft world… it’s great to have choices. But enough is enough. GRT really gets a bad grade this round (D-) with my order on their compression style EGT probes.

As par usual, there were zero issues with the mechanical process of ordering these EGT probes. Call them up to ensure they have in stock, order two of them, card info, confirm address… 5 minutes and done. On my porch a few days later. EZ-PZ.

GRT’s Achilles heel, and biggest negative, is their product information and documentation. I had a conversation with Nick Ugolini on this a while back, and he told me as an engineering tech writer he offered to write their manuals for them… for free! They refused. I asked another buddy of mine who uses GRT if he would go that route again with any future aircraft… he said no. Why? Not because of the quality or the functionality of their products —which is excellent— but again, with no robust documentation you spend way too much time on the phone with them and/or hunting for information that should be right at your fingertips.

GRT’s Achilles heel, and biggest negative, is their product information and documentation. I had a conversation with Nick Ugolini on this a while back, and he told me as an engineering tech writer he offered to write their manuals for them… for free! They refused. I asked another buddy of mine who uses GRT if he would go that route again with any future aircraft… he said no. Why? Not because of the quality or the functionality of their products —which is excellent— but again, with no robust documentation you spend way too much time on the phone with them and/or hunting for information that should be right at your fingertips.

Case in point. I called GRT to get info on their compression style EGT probes because, once again, there is literally ZERO information on these on their website. I asked about any recommended processes I should know for mounting these into the exhaust pipes? How does the configuration work exactly? Do they sell the threaded mounting bungs? (no); Any preferred vendors or sources of supply for the threaded mounting bungs? (no); Now, admittedly this last one I’m fuzzy on, but I swore I confirmed that the required mounting bung threads were 1/8-NPT. Apparently not. Neither was that information provided (via product info sheet) nor offered when I was clearly asking every question I could think of regarding the install of these compression style EGT probes.

Well, when my 1/8-NPT threaded stainless steel mounting bungs arrived today from McMaster-Carr, I quickly noted that they were not the correct size. But what was the correct size? After 15 minutes of no joy in trying to figure out this odd thread size, I punted and called GRT, leaving my message to have them call me back later as the standard process goes. And a half hour later got my answer: M8 with 1.0 pitch. Yes, being in the good ‘ol US of A we tend to use ASI vs metric, but I do use metric hardware enough to know that the standard pitch for an M8 thread is 1.25, not 1.0. Hmmm?

After a good 30 minutes of searching in vane on the Internet for a vendor that sells a stainless steel M8-1.0 threaded mounting bung, I gave up and finally went to the only source of supply I could think of that would have such an item: Ebay… well, China to be even more exact. Yep, there they were! Less than 20 bucks for 3 of them shipped from Shanghai and only a month to get here. Thanks again GRT!

In other news . . .

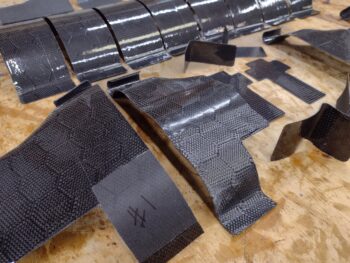

Today I finally finished the trimming and shaping of the majority of inner CF baffles. Over the past few days I’ve done a few redo layups since using tape on the forms there were few quality issues I had with some of the baffles. Thus the redoes.

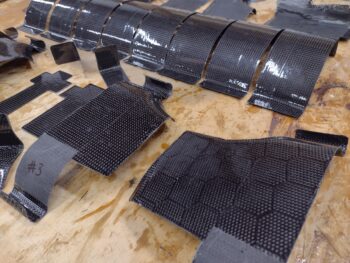

With the glossy surface the lights blanket out some of the CF print, so I grabbed these lower angle shots to show different perspectives on the CF.

And as a reminder, the aft inner baffles are the same print as prop spinner and flow guide.

Overall I’m very happy with how the CF inner baffles turned out, and plan to start mounting them to the engine… after I get the aluminum fin standoffs made up and mounted to the cylinders first.

Those baffles are just toooo pretty. You are going to need see through cowls to show them off. …and the print matching the spinner? Show plane awards looming!

Thanks Dave! Yeah, a shame that 95% of the time you’ll never see them… except a peek at those aft ones!