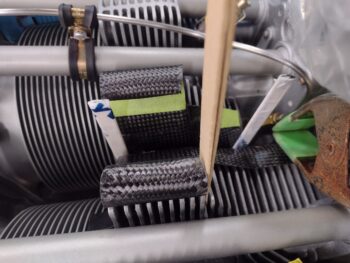

I started out today by focusing on trimming up the remaining engine inner baffles that I had not gotten to yet, which were primarily the top outboard inter-cylinder baffles. Knowing that Steve Beert is The Godfather of CF inner baffles I sent him a quick message asking him a few questions specifically regarding these inter-cylinder baffles… in fact, I sent him this pic below to clarify exactly which ones we were discussing. We had quite an exchange over text on installing the baffles.

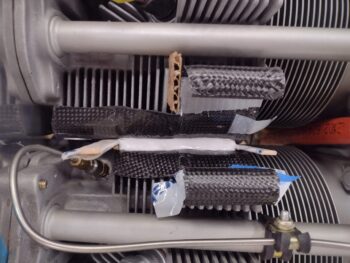

Then a bit later Steve called me with yet even more information, tips and builder tricks on these inner baffles. We spoke for a good 45 minutes, where he also went over some of the background of the design (Terry Crouch having done the airflow math and primary design with a lot of input by Gary Hertzler) of this style of inner cylinder CF baffles. I sent this pic below as well of the bottom-side outboard inter-cylinder baffle with a question to clarify some info Steve have presented to me.

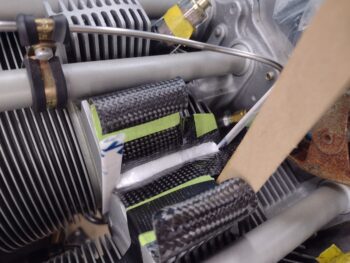

After talking to Steve, with now a bunch of informational arrows in my quiver, it was time to get to work. I finished trimming and cleaning up the top outboard inter-cylinder baffles, or the baffles that Steve nicknamed: “The Starship Enterprise” and set them into place between the cylinders each side. Note the taped popsicle sticks on each end to keep the separate baffle segments both in the proper left-right position on their respective cylinders, and also pressed firmly against each cylinder… the intent here is not to create a gap between the baffle segments, but to account for these two previous mentioned factors.

I then followed Steve’s construction sequence by whipping up some micro with the high temp HTR-212 epoxy. This was a bit tricky both in access to the gap (on a step ladder leaning over the top of the engine) but since I didn’t want to make a mess on the lower internal fins of each cylinder (or the floor, etc.), I had to ensure that the micro wasn’t too runny… thus the medium thickness micro —with emphasis on the thicker— was a bit trickier to stuff down in that narrow gap without it wanting to come back out with whatever implement was being used to get it in there (a variety of thicknesses of stir sticks). Patience won over though and I finally got a good bead of micro in on each side.

I’ll note that Steve used West’s black dye in his micro in this application, but since I didn’t have any on hand I will simply paint the white micro with hi-temp black spray paint.

Although the weather isn’t as freezing cold this evening as it has been off and on lately, I set up a heat lamp under each side of the engine pointing upwards and covered the cylinder areas with some aluminum foil covered insulation pieces to keep the curing micro from getting too cool overnight. And with that I called it a night and left these micro’d inter-cylinder baffles to cure overnight.