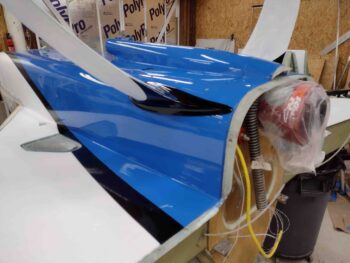

Before I repainted the black accent stripe on the nose/fuselage/strake I cleaned up the fuselage-side landing brake hinge.

After cleaning the hinge, as I did last night on the actual landing brake, I then test fitted the landing brake into the fuselage landing brake depression. I’m very happy with the fit of the landing brake into the fuselage.

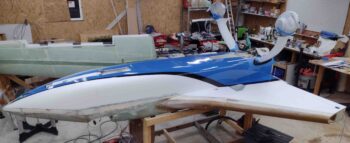

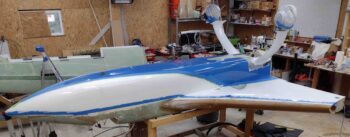

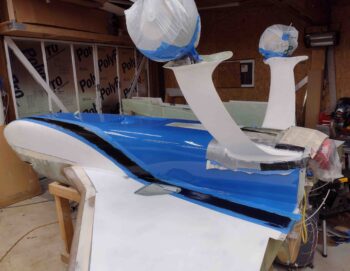

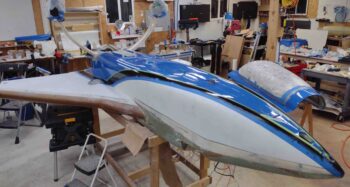

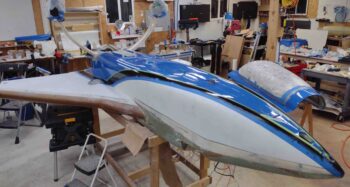

I then repainted the black accent stripe on the nose/fuselage/strakes (see below).

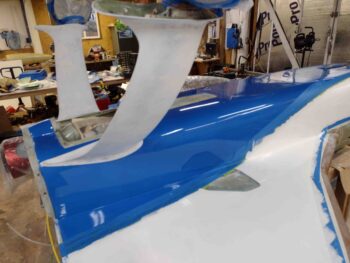

After the landing brake test fit, I then removed the painters tape to reveal the blue border along with my checkerboard bling. There were a couple of paint runs, one on each side, that I scraped with a razor blade. So before I grabbed this shot I cheated and covered these scraped runs with blue tape.

As for the paint, I’m not overly happy with it. Again, it looks great from 6-10 feet away, but closer up you can see some minor runs, brush strokes and dust. Moreover, the painting process itself is hit or miss. It requires a near-perfect application of paint to get it to come out looking nice, and has to be applied very quickly to keep it from drying too quickly as its being tipped.

My major angst with this paint is that there is just very little room for error as it’s pretty much a one shot deal. If there is a hair or piece of debris that needs to be removed as the paint is being applied, you have a window of about 5 seconds before needing to move forward. There is just no wiggle room and it’s a razor’s edge of being an acceptable success or a surface that will require a recoat.

That all being said, the black paint stripe will need another coat.

The nose hatch door would have been a done deal if I hadn’t kissed it with a paint brush while mucking about with painting the nose gear fairing right next to it. With that little blight on the midpoint edge of the nose hatch door, it had to be dealt with. So before I moved forward with the next blue coat of paint on the canopy frame I wanted to see if I could buff out and polish the paint on the nose hatch door.

I wet sanded the nose hatch door paint starting with 1200 grit, then 1500 grit and finished up with 2000 grit. After the sanding I used cutting compound, then polishing compound to see if I could bring back a shine. Nope. Nada.

Now, to be clear, I was told that I would be able to buff out this paint. I have done a fair bit of automotive style base coat/clear coat painting effort, and this paint does not buff out like clear coat, although when cured it is super glossy like clear coat.

With that, I cleaned the surface twice with acetone, then a couple rounds of denatured alcohol. I then wet sanded the surface with 500 grit paper in prep for another coat of paint.

With my newfound knowledge in hand, I pressed forward with my blue painting tasks. I’ll note that each time I painted the black accent stripe I had a fair bit of paint left over in the cup when finished. Using the amount of total paint used for the stripe as a baseline, I of course thought I had enough to not only paint the canopy, but the nose hatch door as well. Well, as par usual with this painting effort I shot myself in the foot by not mixing up enough blue paint to complete the canopy frame painting [I think a big difference in required amount was using brush only vs foam roller, which soaks up a lot more paint].

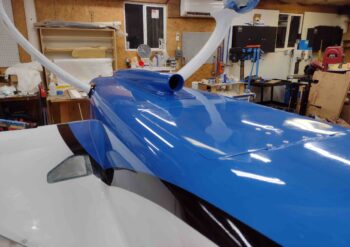

Not to toot my own horn, but I actually nailed the paint application on the aft 80% of the canopy before my paint started running out. This caused a too thin application for tipping on the front canopy skirt area.

I could tell that the paint was too thin on this forward area, and my attempted tipping was going to leave some brush grooves that would require a fair bit of sanding. Begrudgingly of course, I accepted that this was going to require yet another coat. Thus, to mitigate the amount of future sanding required I simply smoothed out the paint on the forward frame/skirt with the roller.

Here’s the aft frame of the canopy… and it definitely is acceptable. So, the goal is to repeat this success for the entire canopy frame (groan).

Back into the realm of my great looking “6-foot-plus” paint job, I mounted the nose gear fairing and doors to check their fit and appearance. Also note the black painted accent stripe.

Here’s another shot of the nose showing the nose gear fairing with the gear doors closed.

And a wider angle shot of the repainted black accent stripe, installed nose gear fairing & gear doors, as well as the repainted blue canopy frame.

When I repainted the nose hatch door it came out ok. There were definite streaks I saw from tipping, so I rewetted the brush just a tad to smooth out the streaks, but the paint had clearly passed the stage where it wanted to play nice, so a mottled mess ensued. By this point I’ll admit my frustration got the best of me. I grabbed the roller, loaded what little bit was left in the tray and recoated the door before aggressively tipping it out.

Well, this paint was not going to reward such rogue behavior! I don’t know if it was the reapplication action of putting on a second coat, or that my roller and/or brush got contaminated, but the resulting coat was simply awful… clearly yet another sanding and recoating required.

The “contaminated” paint carried over to my taxi light frame as well, which too turned out awful and will need yet even more sanding and a recoat.

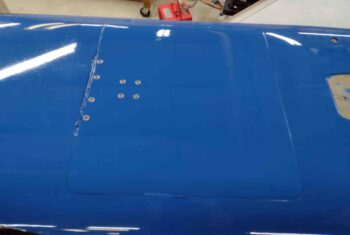

The patch on the fuselage near the firewall turned out acceptable, although there is some contamination in this paint as well. This is the required patch from me sanding through my tape into the paint on the sidewall.

It does have just a slight edge to it, and that dust stuff going on. I’ll watch it and evaluate further. Yes, call me crazy but I’ll sand this first patch coat down and reapply another coat.

Here’s a shot of the patch from a few feet away. Time will tell how noticeable it is.

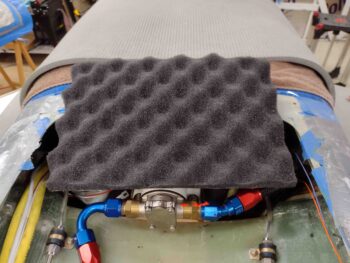

Wanting to clear my thoughts of a not-so-stellar painting day, I tackled the final removal of the half of the oxygen bottle mounting tube (I had taken it off while it was still somewhat pliable then taped back into place). I’ll lay up the other half in the next day or two.

And with that, I closed up shop and called it a night.