Ok, folks… yes, I’ve been out of it for a bit. As some of you may be well aware, we had a good little cold spell here.

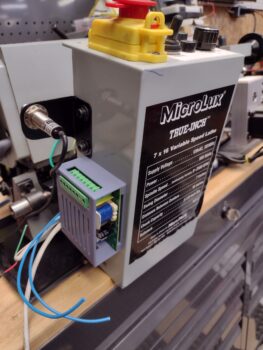

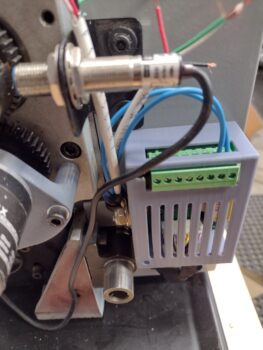

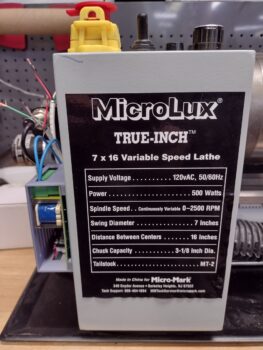

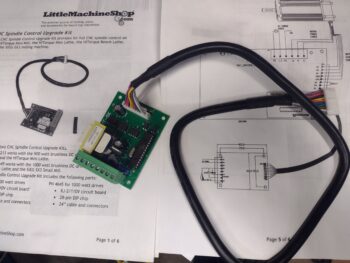

During the cold weather I was digging in deep to get spun up to get my lathe CNC online. I got a good ways before realizing that I need to upgrade my lathe software to do the CNC I need to do, so that will be another week or so.

Meanwhile, in needing to use my truck I had some issues with it that I needed to tend to, including installing both a new battery and alternator. Moreover, I’m fairly certain that this last round of really cold weather was the straw that broke the camel’s back in regards to my well water pump dying. Another near 2 days in sourcing a new one and getting that installed.

I would say that I’m ready to jump back into the Long-EZ build —which I am— but I’m heading out for a long weekend that I surprised Jess with, so I’ll be back on it for another day or two before heading out on another short trip, just for fun. Next Monday I plan on digging back in hard core on the build (whew!).

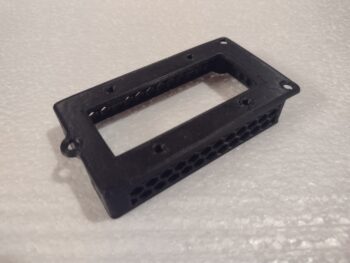

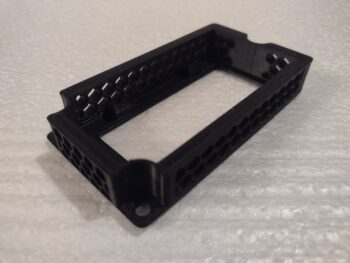

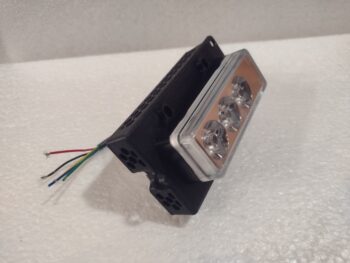

As for today’s build shenanigans: a number of days ago I added a little meat around the edges of the wing leading edge light mounting bracket (in Fusion 360 CAD) … about 0.05″ each side for more space for the 3 mounting screws to secure it. I then 3D printed a thin mockup of the new bracket version to allow me to use it more as a template for marking the aluminum stock for cutting.

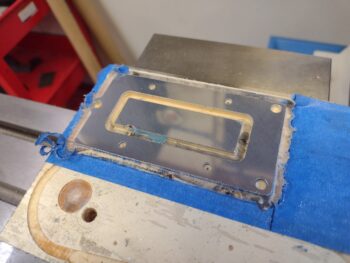

Looking around the shop for exactly what stock I was going to use, I settled on 0.025″ thick 2024. Here I’ve marked up the 2 pieces that I’ll machine to make up the wing light mounting brackets.

I then cut the 2024 pieces…

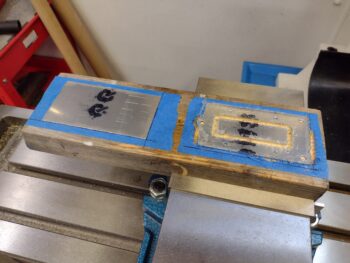

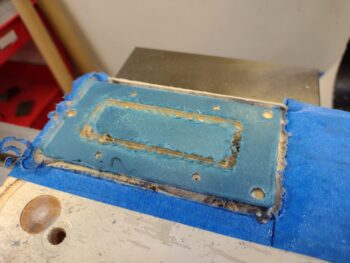

And did my favorite blue tape and super glue hack to secure them to a scrap 2×4 for milling (yep, you can’t take the Neanderthal out of a Neanderthal “machinist!”).

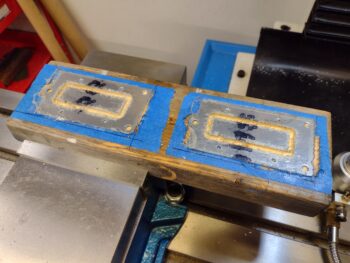

I then prepped and machined the first landing light mounting bracket …

then did the same thing for the second one.

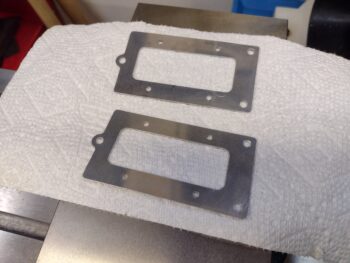

Here we have the 0.025″ thick 2024 wing lights’ mounting brackets, after I cleaned them up just a bit. In the next day or so (weather dependent) I’ll clean, prep and paint them.

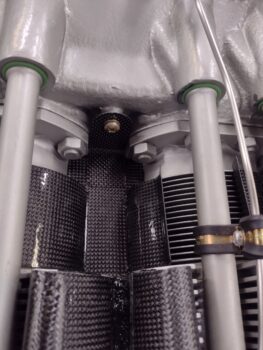

My immediate goals are to finish up the aft lower engine baffling, and also get the stainless steel compression-style EGT probe mounting bungs trimmed down on the lathe (for weight) so I can get them welded into place and operational. Over the next few weeks I’ll be working to finish up the engine stuff to get it finalized, including the firewall. When the weather warms up enough to start slathering up the bird with micro to finish it in prep for paint, I want to be ready to get that ball rolling.