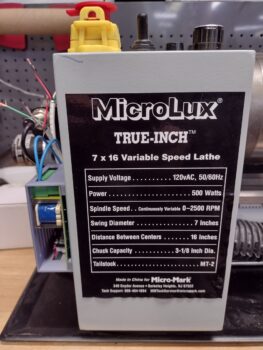

Today I continued my work to finally finish the CNC conversion on the lathe… it’s way overdue. I’ll also again highlight that with the weather colder it’s a good time to do tool upgrades and implementation since big epoxy-based tasks are a non-starter currently due to low shop temperatures.

I’d say the primary hole in my plan for integrating this new CNC spindle control board into the lathe control system is analogous to my GRT rant a while back: documentation. While the install docs that came with the control board have the basic install covered, they don’t go into any detail on how it integrates with the CNC control system I have, so I will be diving deeper and making a few phone calls over the next 2-3 days.

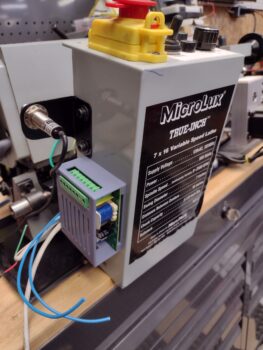

Thus, the main goal today was to simply get the new CNC spindle control board, housed in its nifty 3D printed case, mounted to the side of the lathe’s electronics box.

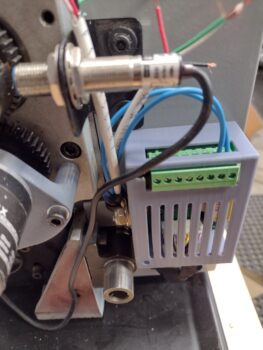

The blue wires connect the CNC spindle control board to the lathe’s AC power mains.

I said the space was tight inside the lathe’s electronic box… too tight to mount the new CNC spindle control board inside there. But even the connecting cable from the new externally-mounted board to the existing interior board takes up a ton of space. It’s the big black cable that looks like an oval race track.

I then closed up and re-mounted the lathe’s electrical box.

I incorporated a reinforced hole on the side —in my design of the CNC spindle control board’s case— to allow for mounting a wire-securing Adel clamp.

As a reminder, here is the CAD model of the case I designed for this new control board.

A front view of the freshly mounted CNC spindle control board housed in its 3D printed case. The front of the case is open to allow for installing the control board into the case, but also so that when the lathe cover is installed . . .

… as it is here, then the end cover serves as the de facto front wall of the CNC spindle control board case.

… as it is here, then the end cover serves as the de facto front wall of the CNC spindle control board case.

Since I am clearly getting the lathe up to snuff to use it, I also pulled the 5″ chuck off the lathe to swap it out for a new 4″ chuck. The 5″ chuck is simply to big and heavy, causing way too much vibration for this size lathe to handle.

Here is the new 4″ lathe chuck in the box… which I bought over 6 months ago?

And here is the new 4″ chuck installed on the lathe.

Inching closer to have the lathe ready for real world CNC ops!