Again, a 2-day post here . . .

Day 1 was the big swap. I loaded up the canard this AM and with the “outboard wing” (now canard buffing) sawhorses that I reinforced with cross-bracing loaded up last night, delivered the canard to Phil’s shop.

I met Guy there where he helped me load up the right wing in the trailer, while we placed the top cowling in the back of his covered truck bed. I also had the aft nose/avionics cover in my truck cab.

After delivering all that back to my shop…

we then loaded up the left wing in the trailer and the bottom cowling in his truck and delivered that to Phil’s shop.

Here we have the left wing in Phil’s shop.

And a wider view of the canard and left wing at Phil’s shop.

By late into the evening I had finished cutting and terminating the big yellow starter cable in the nose and installing it onto the bottom terminal of the starter contactor (anodized gold box center left of pic), which in turn has a big yellow cable that connects to the battery contactor (middle, black cylindrical). I also mounted the ANL-40 inline fuse block and connected the B-lead from the alternator to it, and from it the cross-connect cable to the battery contactor. All in the forward nose battery compartment, of course.

Day 2: Phil had some slight break-throughs on the canopy’s blue paint, so this morning I mixed up a small amount and took it to his shop and spent a couple of hours touching up those break-throughs.

Here we have Ray in the foreground working on the canard, with Phil behind him working on the left wing. Behind Phil is the canopy, ready for its final buffout and ceramic coating after a minimum 24-hour paint cure.

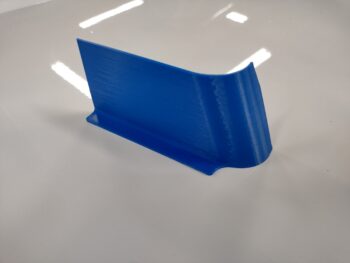

Back at the house I spent a couple of hours in CAD drawing up this seemingly simple protective cover (from fingers touching a potentially powered circuit) for the ANL-40 inline fuse.

My dimensions must have been spot on since this is the first and only 3D print I did of the protective cover… here being test fitted into place. I’ll probably Velcro it to the Napster bulkhead and call it good.

I then got busy fitting, cutting and flaring the 1/8″ 3003 aluminum tubing for the forward brake line cross-connects. I had already made these before, but lost them either in moving down to NC or in the hurricane/tornado that hit my hangar back in 2019.

Here is the initial fitting of the 1/8″ 3003 aluminum tubing forward brake line cross-connects for the left side (pic 1) and the right side (pic 2). I need to get the brake lines installed and square away before I start running wires aft of the Napster bulkhead.

Pressing forward!