Yet another 2-day update here…

I started off Day 1 checking a number of various electrical data points, including verifying and changing a couple of components connected to the Battery Bus. The primary component swap was pulling the fuel pump off the battery bus and placing it on the E-Bus, swapping it with the Pitch Trim System. My thought process was fairly simply: what switches might a kid sitting in my bird, unattended, start flipping. And also, what might I leave on connected to an always-hot buss?

The pitot heat relay and wiring is physically close to the battery buss and thus connected to it. I considered moving it off of it as well, but it has 2 fail safes with both an indicator light and, more importantly, a 40-knot airspeed switch to allow it to power up (specifically to keep it from staying on if the master were to be left on, or in this case just in general). Now, while the fuel pump does have an indicator light and a flip-up switch cover, I felt it the worse of these 2 evils to be connected to the Battery Bus.

I then got to work repairing a triplet of cables that ripped out of a terminated pin on the aft primary nose gear actuator connector. To repair it, I crimped the 3 wires into a much larger single wire and then terminated it with a pin that was then set into CPC (Circular Pin Connector) P1 on the front of the NG30 cover (that is now installed). I also finalized installing the wire-securing clamps on the back end of these two nose gear connectors.

I then spent nearly an hour going through the rats’ nest of wires to get them somewhat sorted out, and out of the avionics bay and NG30/canard area so that I could climb into the bird to verify the rudder/brake pedal installation positions.

Of course to do that, I first needed to install the front/pilot seat cores, which I did in final fashion by thoroughly cleaning up the seat pan and seat back before pulling the tabs off the cores’ Velcro strips and mashing them all into place…. including the right armrest pad.

This concludes yet another major milestone on this build since it officially closes out Chapter 26 – Upholstery and places it squarely in the COMPLETED column!

This allowed me to install the rudder/brake pedals and get a good idea of where they needed to be installed, which I did an initial temp install before calling it a night.

The next morning, I pulled the 1/4″ tubing fittings out of the rudder/brake pedals’ master cylinders to install 1/8″ fittings for the Nyla-flow feeds from the Parking Brake Valve. The aft fittings on the master cylinders are 90° 3/16″ fittings that will connect to the separate brake fluid reservoirs.

That all being said, note the exit point of the in-side-wall rudder cable conduit at lower left in the pic below.

First, here’s another shot looking from the forward nose end of the left rudder/brake pedal with the 1/8″ Nyla-flow tubing from the Parking Brake Valve (aka wheel brake caliper) into the master cylinder. The aft (upper) 90° 3/16″ Nyla-flow fitting is currently not connected.

Now, again, note the 3/16″ Nyla-flow rudder cable conduit exit out of the left sidewall, in the very upper right of the pic below.

I pointed out the rudder cable conduit exit on the sidewall to discuss a requirement that comes with installing the Hidden Bellhorn on the rudders: a spring that allows for continued movement of the rudder cable after the rudder’s hidden bellhorn hard stops against the internal wall of the rudder. The claim is that without this spring that you may not have any forward movement on the pedal to then engage the brakes [To be clear: the Long-EZ’s rudder/brake system is set up that the rudder must be fully engaged before any braking action <continued pedal pushing> occurs].

About 2 years ago I spoke with the manufacturer of my rudder/brake pedals, Dale Martin, about his original statement to me that with his pedals we don’t need these springs. This is why I exited the rudder cable conduits out of the sidewall where I did. Moreover, we discussed how little forward movement on the pedal is required to activate the brakes after full rudder deployment (around 1/4-1/2″). Also, there are a distinct few builder/fliers out there (Wayne Blackler, Klaus Savier, etc.) that do not have these springs installed out of personal choice (more direct rudder response, for one) and have had no braking issues to report. Conversely, Marc Zeitlin considers them mandatory.

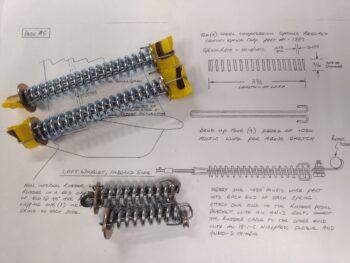

In assessing the requirements levied against us builders in the hidden rudder bellhorn plans, I decided after re-reading these impassioned arguments on the COBA forum that I would simply split the middle… literally. I spent a good deal of time on the Century Spring website as well as McMaster-Carr looking at the specs of various springs (which are given in these instructions… upper right of background sheet), before deciding to simply cut an extra spring I had on hand in half and press forward in my heretical shenanigans (the 2 full ones are from the Cozy Girrrls).

Not surprisingly, the Cozy Girrrls got a little fancy with their springs by adding a washer on each end that they then terminate the 0.05″ wire back into. Since I cut one spring in half, one end of each of my springs now has non-flat/grounded ‘free-radical’ spring coil on it. Thus, I copied the Cozy Girrrls and drilled out an AN970-3 wide washer to cover these ends… now a distinct characteristic of these abominations that I created.

I’ll note that a full-length spring (3.75″) can be compressed by 1.75″, but the specs states that normal compression should be no more than about 0.8″. Now, if we halve that we get a normal compression of over 0.4″, but if needed over double that. The numbers show this will provide more than enough throw past normal operating parameters in case a mushy brake (air in the lines, etc.) is encountered.

Finally, I grabbed this pair of pics below to show the amount of rudder conduit that would have to be extracted from the sidewall with the standard spring length (pic 1) as compared to my new “petite” spring (pic 2). Clearly a lot less work with the petite spring in getting it installed.

They say confession is good for the soul… so here’s my confession. And with that, as par usual, I’m pressing forward!