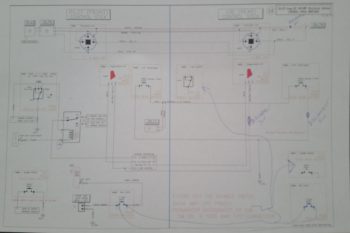

I’ve spent a few hours over the last couple of days updating my Control Stick Switches wiring diagram (#14) which institutes a major redesign on my control stick switchology. This is of course is the first draft with all the foundational components in place. It still needs much refining. For example, I still need to design & emplace a switch into the mix that will allow me to disable the GIB control stick switches for those times when I’m hauling kids (or Marco!) in the back, who may be just a tad too inquisitive and want to get handsy with the buttons! (sorry for the poor pic quality…)

I would say one of the big electrical system breakthroughs I achieved over the past week is taking the stock ON-NONE-(ON) toggle switch located just to the left of the china hat switch on the Infinity stick grip, and making it work to suite my design goals. I wanted it to control my COM1 ↔ COM2 radio swap [COM1 = Garmin GTN650 & COM2 = GRT HXr EFIS-controlled Trig TY-91] and wasn’t past swapping out this switch if I needed to, but I definitely wanted to make it work if possible. In my monkey brain I intuitively “knew” when I bought these sticks from JD that I should be able to design what I wanted circuit-wise.

With that extra momentary ON position when the switch is toggled aft, I wanted a way to use that switch for controlling the frequency flip-flop for BOTH radios, as well as the COM1 ↔ COM2 radio swap. This is where digging into the installation manuals and discussing with GRT really helped, since there is no remote freq flipflop feature on the GRT HXr (this is accomplished with a button on the right side of the EFIS). Since the inherent features of the GRT HXr EFIS removed the remote freq flip-flop feature off this switch’s ‘to-do’ list, I was then left with my COM1 ↔ COM2 radio swap requirement, plus controlling ONLY the COM1 freq flip-flop.

As a point of clarification, remember that Garmin doesn’t allow third-party vendors (AKA GRT) to remotely control their radio functionality through a separate component like an EFIS (yes, there are remote functions via switches/buttons and some SL30/SL40 command features, but not full control of the GT650/GNS430 communications functions). Thus, my setup is the Garmin GTN650 (COM1) as a separate radio controlled totally outside of the GRT realm, and then a remote Trig TY-91 transceiver (COM2) controlled via the GRT HXr EFIS. The sound and headset features of both of these radios are controlled via a Dynon Intercom. It is the COM1, COM2 select feature of the Dynon Intercom that the stick mounted toggle is controlling. The COM1 freq flip-flop is wired directly to the GTN650.

Utilizing a relay, my design functions such that COM1 is always the default com radio unless the switch is pushed forward, thus driving the relay switch off the N/C (normally closed) COM1 side to the N/O (normally open) COM2 position. Since I control the COM2 radio freq flip-flop on the EFIS there’s no issue with not having the COM2 flip-flop feature on the stick toggle. Obviously, in the default COM1 position –which I’ll be using 80-90% of the time– engaging the toggle switch in the MOMentary down position has no effect on COM1 ↔ COM2 radio selection.

Ok, so I’m extremely pleased with this setup since it perfectly matches the capabilities of my planned panel components. One issue resolved, 287 more to go . . . . ha!

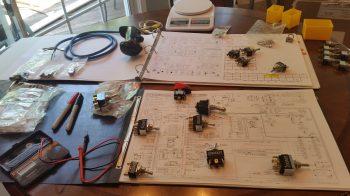

In the pic below you can see my inventory and ID’ing ALL the switches I have on hand. Since I had some extra switches that I got from JD when I bought the Infinity stick grips, I was checking out the weight of the larger Carling (B&C) switches vs the smaller toggles. If you’re curious: 3 B&C switches weigh around 0.18 lbs vs. 3 mini-toggles weigh about 0.04 lbs. As you can see, I am reassessing my panel switchology and trying to attain some weight savings where I can. I will say that using mini-toggles adds time and complexity to the electrical system build since those switches must be soldered in vs the nice FastOn connector tabs incorporated on the B&C switches.

I also knocked out some of the more background tasks for both the electrical system and in prep for getting back to the build. I made a run to Harbor Freight and stocked up on some supplies. And as I was out and about I got a battery for my ever-trusty & ever-present epoxy-laden build WATCH, and got it back online. And I stopped by FedEx to buy a long 12 ft length of 48″ high plotter paper to lay out and start designing my wiring harness in real dimensions, later on when time allows.

Finally, I spent about 3 hours last night finding/researching/purchasing replacement mini toggle switches, and submitting a decent-sized order with Mouser. These orders bring me current for all the outstanding bits & pieces (resistors, relays, AMP CPC connector, switches, pins, sockets, etc.) that I need up to this point for my electrical system build.

From here, I plan on finalizing the design and update on my stick wiring diagram and then I’ll transition into focusing on the real build stuff!