Today I spent the first half of the day getting a safety inspection done on my motorcycle. Just as they were finishing up the inspection it started to drizzle, which then turned into a fairly steady light rain for most of the day. Which of course meant not getting the garage organized since most of the stuff has to come out so that I move & reorg the stuff inside. Oh, well.

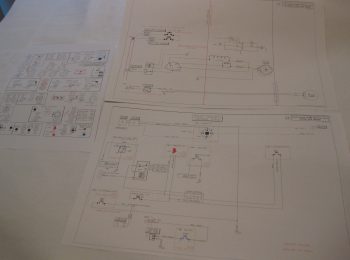

So, after the inspection was complete I did a fair amount of research on the heating system. That rolled into updating a few wiring diagrams to reflect the updated electrical requirements, which included: the removal of the GIB Infinity control stick, resulting in the need to update the switch diagram, and of course updating the newly created Heating System diagram (these 3 are shown below).

I then went down to the shop and finally cut the 1″ x 1″ Chromoly steel engine mount square tube extrusion into 2 “L”-shaped angled pieces. I know some may question exactly why I’m throwing in only one mount of 4130 steel. Well, I was actually going to install 2 4130 steel mounts catty-corner from each other, but when the bottom mounts required the use of 3/16″ angled extrusions, I simply decided that between the weight and cost of buying more/thicker 4130 steel, I would punt and simply put only the one top side in. Yes, I considered both top engine mount extrusions being 4130, but now with my engine weighing in heavier, I’m going to employ a little Operational Risk Management here and just go with the one side to keep the weight down, and to keep from having to buy more metal! A little odd? Perhaps. But I’m going to be a little eccentric and go with this!

By the way, after I got it all cut, I matched it up to the engine mount and it was a good match!

Ok, perhaps tomorrow I’ll actually get around to reorganizing the shop in order to be able to move around and build in it!