Today I continued pressing forward with the lathe CNC conversion by updating the Acorn CNC control software from version 4.64 to 5.08.

As I was writing out my task to-do list for the day, I got a call from my good buddy and fellow canardian Marco. We of course discussed Long-EZs and projects, but we mainly discussed machining… specifically lathe CNC operations. The call was perfect timing since I had a number of questions regarding employing CNC on a lathe, which is a much different animal (a more hybrid blend of CNC using less Fusion 360 CAM and a whole lot more Acorn CNC macros, or “canned” lathe cycles) than CNC on the mill.

When setting up an Acorn CNC control computer, it must be a dedicated CNC computer. The Dell laptop I have has not been connected to the outside world via Internet in years, to keep Microsoft from sneaking in software that may crash a CNC program. However, the catch-22 is that when new Acorn software is released, it is based on the current Microsoft .NET framework, with all the latest updates. Thus, the first step in updating the Acorn lathe CNC software is to “briefly” connect the computer to the Internet and do a controlled Microsoft Windows update. As you can imagine, this took multiple hours (pic below from later at night after new Acorn CNC software update to v. 5.08… note column of white buttons at left on gray panel: these are new pre-set lathe cycles that require simple parameters to be inputted before executing, an upgrade over the older software that didn’t have these pre-programmed macro/canned cycles).

While my dedicated CNC laptop was getting all the security and Microsoft .NET framework updates, I pulled down about a half dozen panels of pink fiberglass insulation that were clearly in use by unwanted intruders. Yes, I may have won some battles, but the squirrels and giant field rats won the war. The ceiling insulation is on its way out. Currently my shop smells like a bathroom in an inner city bus station… the ever-present smell of squirrel piss wafting through the air.

I loaded my truck with a bunch of the nasty removed insulation panels and took them to the dump. Upon my return —as the CNC computer slowly did its update thing— I did a good round of cleaning in the shop.

The good news is that the fewer the insulation panels, the less places for the rodents to invade and occupy. And yes, I’ve tried traps, poison, ultrasonic blasters, barriers, etc. to keep them at bay. The bad news? Did I mention, it’s still cold?? So no major epoxy-based tasks until it warms up.

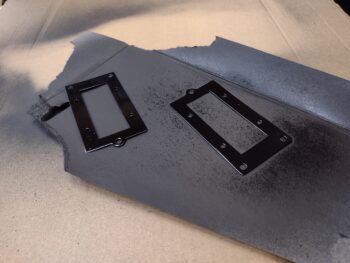

During yet another phase of my CNC computer update (it took about half the day), I cleaned up the inside corners of the wing leading edge light brackets, tested their fit on the actual lights, then cleaned up the brackets for a round of primer, then a couple of rounds of black paint. I’ll clear coat them in the next day or two.

With the Acorn CNC dedicated computer finally updated with the latest round of Microsoft junk, I once again took it offline and locked it down. I then proceeded to backup my old 4.64 software version (in case the new one crashes) and then updated my Acorn Lathe CNC software to version 5.08 (see pic above). I then spent about 45 minutes updating the operating parameters in the software that is specific to my system (I took screenshots earlier of all these screens).

I’m happy to report that the lathe CNC software is updated, now back to getting it configured to make some chips!