With the white primer that I applied to the “freckles” on the fuselage still curing, I started off today by wet sanding the landing brake, nose hatch door, nose gear fairing and nose gear doors.

The landing brake has some very minor varying surface levels that I refined much further to really dial in the surface smoothness, thus the breakthroughs back into the primer coat.

On the other components, although I didn’t have what I would consider 2 solid coats, I tried my hand at surface finishing those to see if I could proceed into the buffing and polishing stages… but alas, I either broke through in some minor spots back to primer, or I got some uneven paint coloration. Bottom line is that all these components will need another 2 solid coats before they are ready for either final cure or buffing and polishing.

A note on the paint: between self-inflicted issues in my not being diligent enough on surface prep, to needing to do deeper research on the application process, I think I’m finally ironing out MY issues with the paint application. After watching some Epifanes produced videos, I believe that my lack of tipping (very gently gliding a brush over the roller applied paint to even it out) is the root cause of my current problems.

You see, the paint lays down beautifully in about 90% of the areas when simply rolling it on, but then the 10% where there are slight imperfections can’t be worked with a roller. Then later the final finish of these 10% areas become problematic and require a recoat. My epifany is that I can see where tipping with a brush not only evens out the paint for final leveling and subsequent cure/finishing, but it provides a method for quality control. Combine this refined paint application process with a renewed focus on surface prep and I think I should be on the right track regarding paint.

It’s all about learning and dialing it in when it comes to a new system like this.

I had told my little buddy that I’d hang out for a few hours today, knowing that my canopy frame white primer needed a good 24-hour cure time as well. One area I need to start focusing on again as I get towards the end of this build is my true CNC machining/lathing capabilities so I can make some parts for this bird. I figured during these paint and primer cure times I would start knocking out some tasks to get my milling machine, and in turn lathe, CNC’d and online.

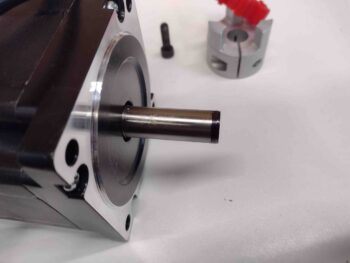

I have all the milling machine stepper motors installed, except the shaft on the X-axis stepper motor is about 1/8″ too long, preventing the motor to be fully mounted onto the motor mount… as below in a pic I took a LONG time ago.

I rechecked the gap and it was right at 1/8″, or 0.125″.

Yes, I should have some fancy way to remove the extra material, but alas, I don’t… so I resorted to my neanderthal machining ways. First by marking the 1/8″ excess with a Sharpie . . .

And then trimming the stepper motor shaft with my trusty Dremel Tool. Not a perfect finish of course, but it will do!

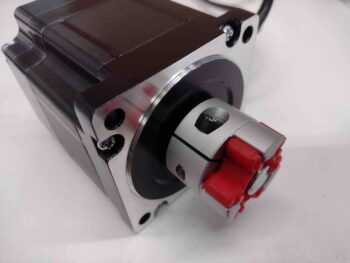

I then remounted the quick connect stepper motor coupler.

And remounted the stepper motor… Voila, it fits. Success!

After coming back from hanging out with my little buddy, I spent about an hour and a half sanding down the white primer coat on the canopy frame.

I then mixed up some gray primer and applied it a good bit thicker than I did the first white primer coat, although the white primer adhered just fine.

With just a tiny bit of primer left in the bottom of the cup, I then stirred in a good bit of micro and applied it to some minor gaps at the junction of the canopy and frame. I also filled a few small divots as well with the thickened primer.

Tomorrow I plan on sanding down the RAM air scoop/hell hole hatch cover and the fuselage before doing another round of blue paint on all those components. The bottom cowling will get sanded, but I won’t do any more blue paint coats on that until I dial in the paint scheme with the top cowling, when the plane is upright.