I guess the actual cleanup will come later, right now everything is in the drying out phase.

And when I say “All hands” I actually mean: Any available space!

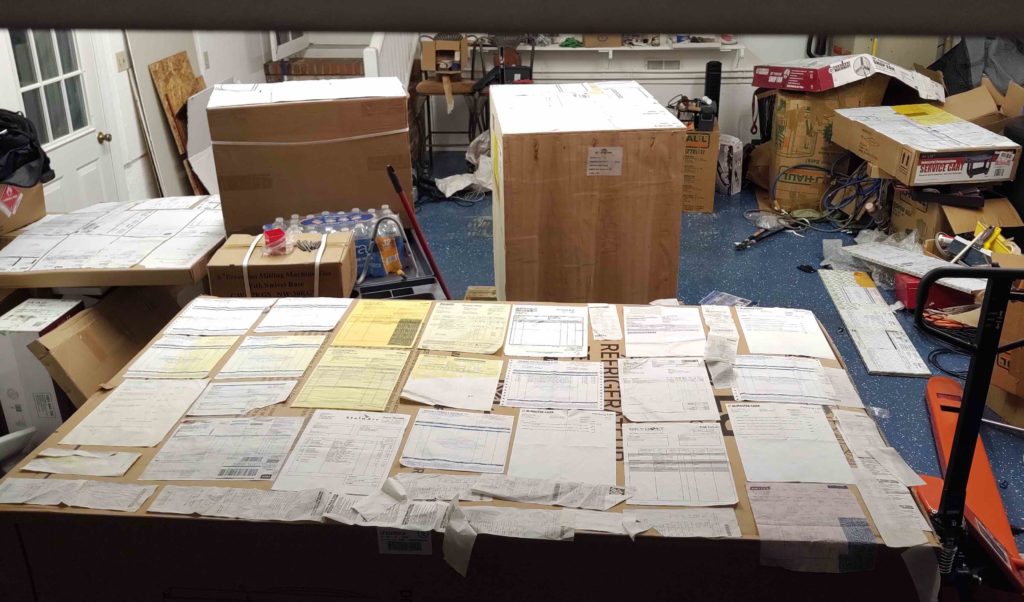

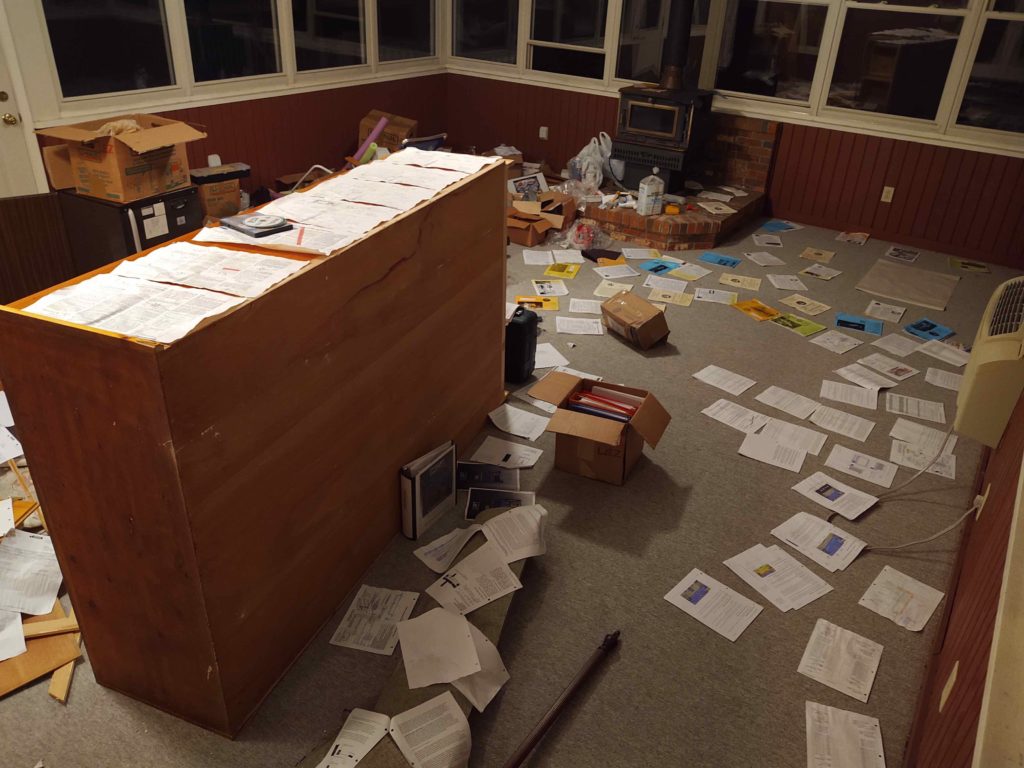

Below you can see receipts and invoices, all from a box that I had labeled “to be posted” drying out on every available flat surface in the garage.

The one house mod I’ve done so far is to rip out a built in cabinet that was in the kitchen, a sort of pantry I guess, to then knock out a space in the wall to place my new fridge. The fridge box is what’s being used for a table in the foreground in the pic above, and the cabinet is lying in the middle of what will be my pool hall/rec room on the back of the house…. a rather large room that came in handy for this task!

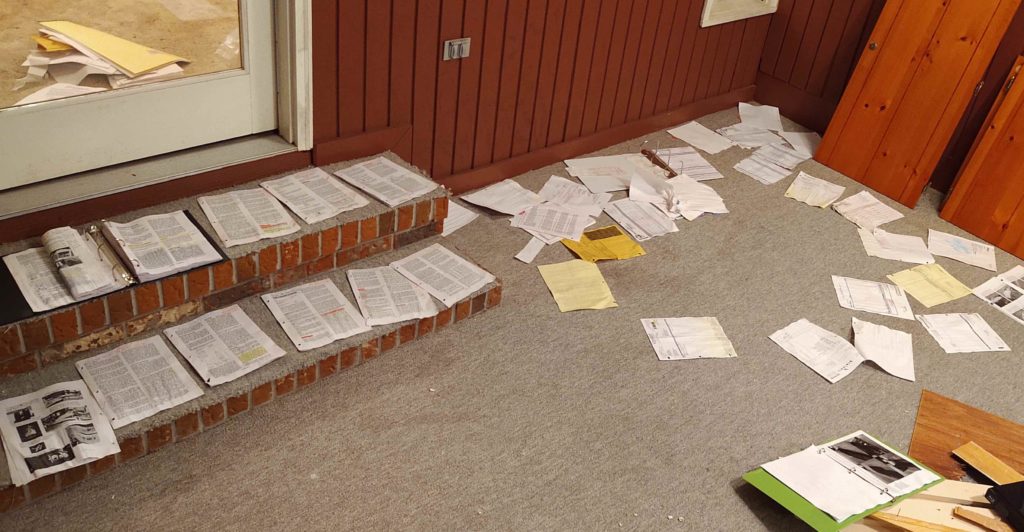

Above you can see old CSA newsletters drying out, while engine info docs are on the floor in the foreground.

Pertinent Canard Pusher newsletter pages are on top of the old cabinet (above) and on the steps coming into the pool hall/rec room.

I guess my actual “first” mod was to rip down some odd (to me) framed wallpaper segments down the main hall. That’s the pile of stuff in the foreground with some papers drying out on the cabinet doors.

Mainly in this pic –on the very left and upper right– I’m showing where I took the wet boxes with parts, components and hardware and literally just dumped them out quickly to spread everything out to dry. If something was of particular importance or overly soaked, I made sure it was dried off completely.

Not shown is my #3 bedroom which I’ll be using as an office and where I dried out the bigger A-pages and plans. Luckily the box that my ancillary plans (engine, A-pages, High Speed Rudders, Landing Brake, Roncz Canard, etc.) were in was on the top side of the VANs engine baffling kit. The baffling was soaked on the bottom few inches of the box, but luckily all the paper plans sat about 6″ higher off the bottom and were almost completely dry. Whew!

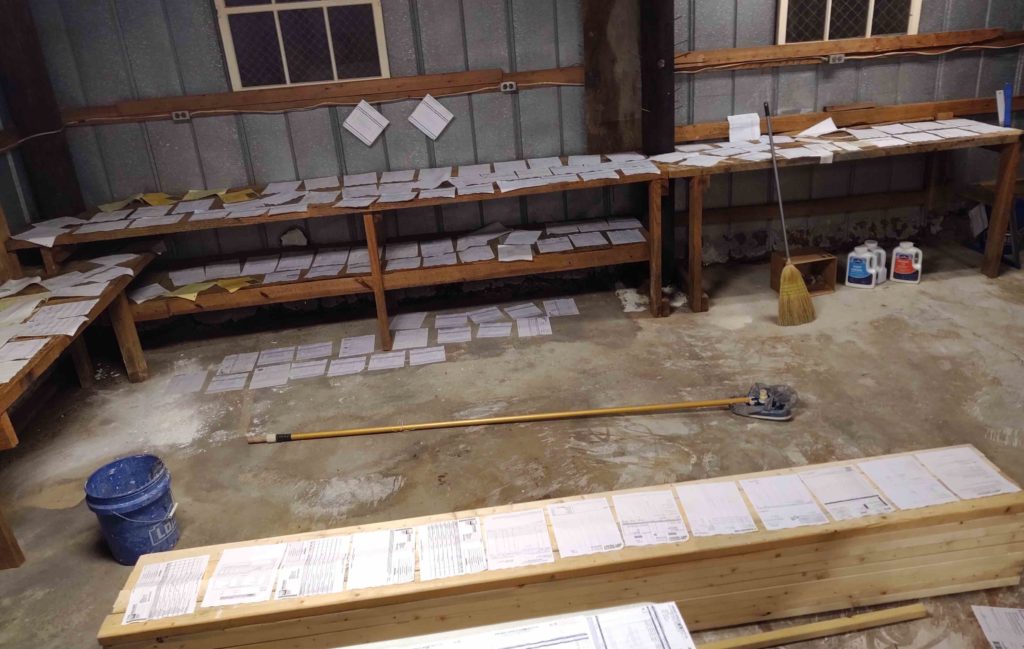

My new (to me) 3-bay workshop was pressed into service as the receipt and invoice drying facility. Again, every available flat surface was used to dry documents.

Along the back wall was the final bunch of receipt and invoices that I got to, dating back to the very beginning from 2011!

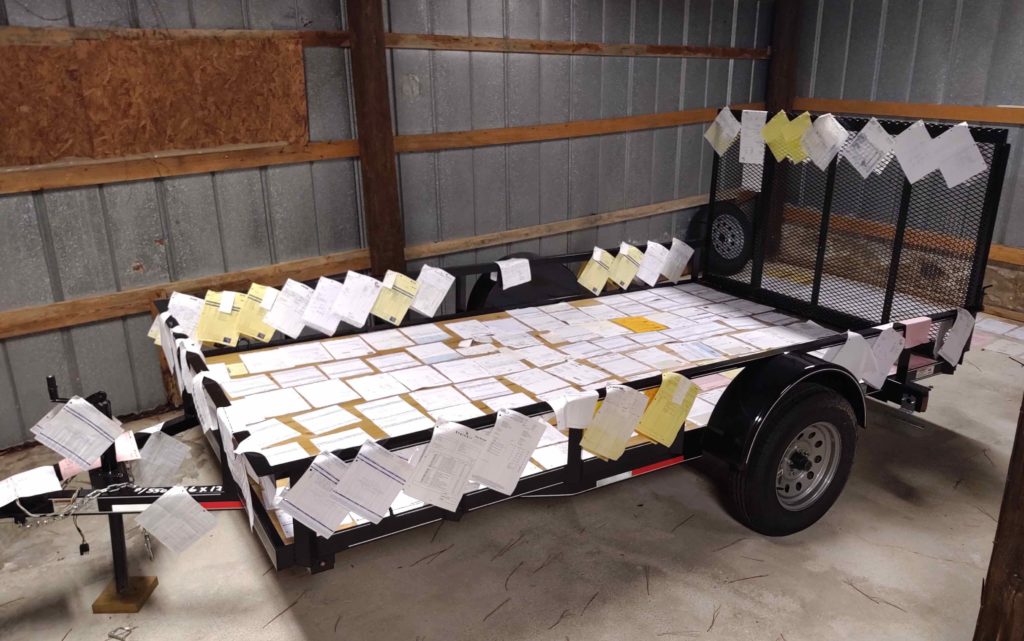

Even my new utility trailer was pressed into service as an invoice drying rack

[Note: I did a cost-benefit analysis and figured it would be cheaper to buy a trailer versus continually renting one… Boy was I right! Fast forward a month and I honestly think it has pretty much paid for itself with the shear number of times I’ve used it!]

All told, I spent 2-3 hours a day for about 4 days drying all these papers and docs out. I had one binder with ink-jet printed docs detailing Wayne Hicks’ strake build notes which were rendered unreadable. But that is maybe 80 pages of reprinting I’ll have to do… not bad for how wet everything was.

A PITA? Yes.

A disaster? No.