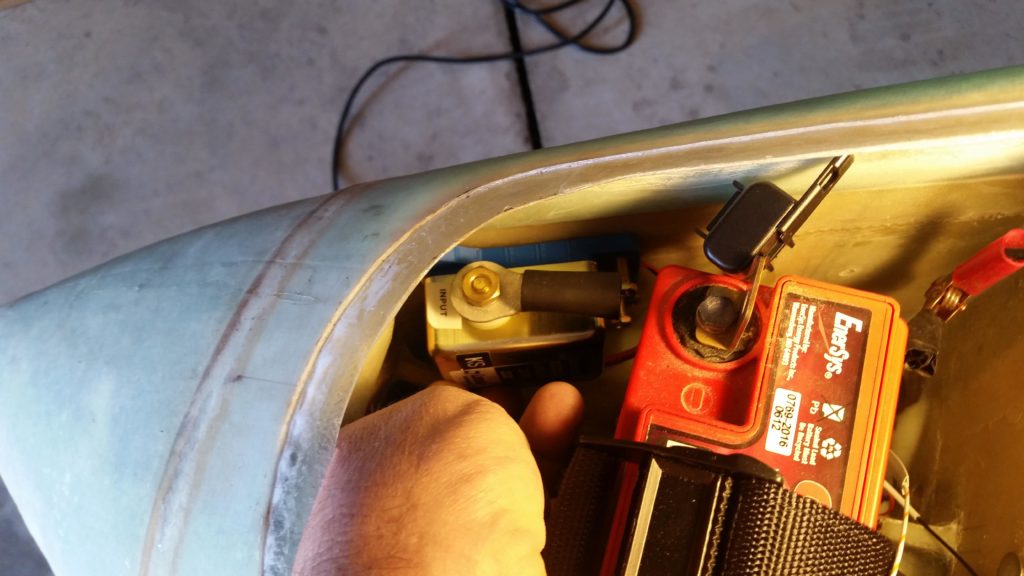

Meanwhile, at my hangar in North Carolina, I was able to check the fit and configuration for installing the starter contactor –on its freshly 3D printed test mounting bracket– in the battery compartment of the nose.

As you might be able to surmise by the pic below, the available space is TIGHT but the starter contactor and mounting bracket just fit.

I then made sure to check available clearance between the starter contactor and the battery for a couple of the large cables that will need to traverse at that spot.

This shot may show just a bit more of where the mounting bracket will get secured to the battery compartment sidewall.

I then checked the fit of my cardboard mockup of the panel that Marco printed out on his plasma cutter. I found a number of areas where the dimensions need to be tweaked, especially around the leg holes and along the top edge, the latter being around 1/4″ short for a good 4 or so inches each side of the center line.

So, it’s literally back to the drawing board for the panel. I’ll then check Version #2 next time I’m down in NC.