Today was another day focused all on ailerons… the left aileron to be exact. I took the left aileron outside and cleaned out the foam and dead micro to leave an approximate 0.4″ depression on each end to create the end ribs with a 2-ply BID layup.

Here’s the outboard end all cleaned up and ready for glass.

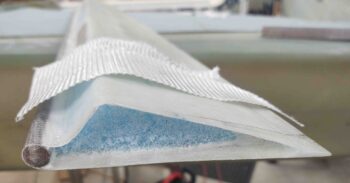

And the outboard end 2-ply BID layup to create the end rib.

I did the same of course on the inboard side, cleaning up all the dead micro and removing foam inwards to 0.4″ deep, as per plans.

I then laid up 2 plies of BID to create the inboard aileron rib.

With the left aileron end ribs curing, I then got to work some on the right strake leading edge root pilot air vent intake hole. I cut the cured glass away that was covering the hole, and then dug out the foam right at the front edge of the hole. I then filled the areas where I had removed the foam with flox to create somewhat of a flox corner here. The flox will allow me to shape the edges of the hole with the flox holding the shape. When I glass the external strake skin I’ll wrap the skin into the hole to create a nice edge and smooth transition into the vent hole.

While I didn’t get any pics of it, which would have been hard to distinguish, I then took about 45 minutes to drill and fill some of the air gaps that occurred on the right aileron. To minimize every bit of added weight as possible, I actually added some micro to the solution and then injected the wet micro solution into the air gaps. It went well with nearly all the air gaps filled, thus eliminating them from the right aileron.

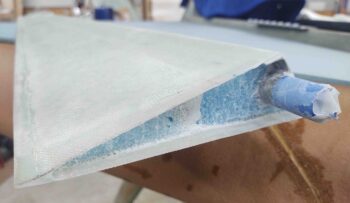

A few hours later I trimmed the left aileron end rib layups. They turned out nice with no issues. Here’s the inboard side. Note that I finally pulled the tape off the A10 torque tube.

And double-checked how far it juts out . . . 1″ as per plans!

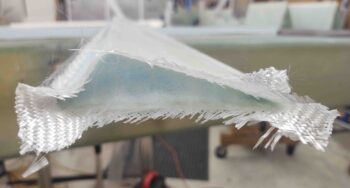

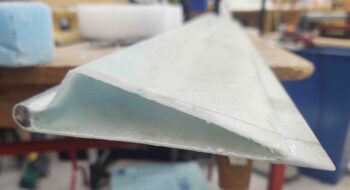

And then trimmed the outboard rib glass as well. This officially completes all the glassing on both individual ailerons.

And a final shot of the finished left aileron.

Over the next couple of days I’ll be focusing on getting the ailerons physically mounted to the wings, as well as focusing my efforts back on the nose to get it finished up before I flip the bird over to shape and glass the bottom strake skins.