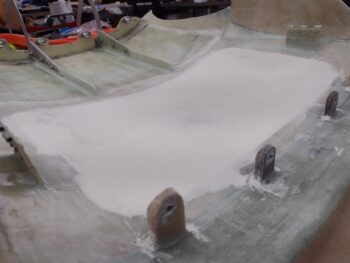

I started out today by giving the inside of the aft nose/avionics cover “window” looking area a quick sanding to rough it up in prep for micro finish.

I then applied a decent layer of micro/West 410 on the “window” looking area of the inside surface of the aft nose/avionics cover. I used fast hardener so that it would be cured by this evening, and then set it off to the side.

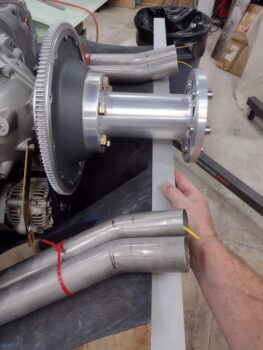

I then called the folks at Jet-Hot to discuss ceramic coatings for the exhaust pipes. I had a very informative discussion with their sales rep Debbie for a good half hour while she went through the different types of coatings they offer. I got off the call with a little bit of homework (research) to do, while they actually had some to do on their end as well. Clinton from Custom Aircraft Parts (who I also emailed about the exhaust pipes) recommended these folks, and I have to say my initial impression of them is excellent.

After reviewing my notes on Mike Melvill’s engine, cowling, prop and exhaust pipe configurations, I then got back into the shop to figure out where the aft edge of the top and bottom cowlings needed to be. After a number of machinations, checks and rechecks, a bit more research here and there, I finally got my numbers dialed in and a straight line drawn across the aft edge of the bottom cowling (note I’m using the screw- driver to point out the line).

Here’s a genera idea of what is coming off the aft edge of the cowling… I marked this line a few days ago on a swag of what this would look like.

I then removed the lower cowling, took it outside and prepped to trim it with my trusty Fein saw… which you can see I did in pic #2. I then sanded the aft edge to ensure it was straight.

Back in the shop I remounted the lower cowling and then double-checked the aft edge with a yardstick to ensure it was straight… it is. Looking pretty good!

Here’s a shot of the freshly trimmed aft edge of the lower cowling.

Alas… sadly the “lamp shade” flow guide on my Catto prop spinner assembly still doesn’t fit with the cowl set as it is. This means I’m either going to have to modify the flow guide or simple sell the spinner assembly outright. I’m leaning towards the former since I like the spinner and they’re hard to come by these days… and I seriously don’t want to take the time to make one myself.

I then went to dinner with Jess and after returning back home, I grabbed the aft nose/ avionics cover to sand down the now cured micro/West 410 finish. Although it took a bit of elbow grease (doesn’t it always), it sanded out nicely.

Although I got most of it done, this was just the initial sanding to knock down all the high spots before it cured rock solid. Tomorrow I’ll fine tune it and either do a few West 410 touchups, or just jump right into a couple rounds of epoxy wipes.

And with that, I called it a night!