Or rather the canard!

I started out today by sanding the pure epoxy coat on the topside of the canard. I began with 120 grit on the long board in a 45° pattern, both to the left and to the right. After I sanded both sides with the long board, I then switched to 220 grit and wet sanded the epoxy finish. This helped get the lower lying areas that should get filled with the high build primer.

Here’s a shot of the right side. For some reason the blog didn’t like the left side pic since I couldn’t load it. Needless to say, it looked about the same.

I then applied primer to the canard. The shot below to the left is the first coat, and the right is the second coat.

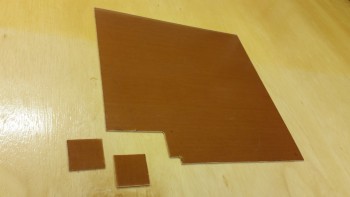

In between priming the top of the canard, and watching football, I cut out the 2 phenolic support pieces that will be embedded in the NG30 cover for the AMP CPC connectors.

I also cut the 8 pieces of UNI for the new elevators that I will be rebuilding here in the next week.

In total I added 3 coats of primer. I’ll wait until its cured tomorrow to block sand it.

Also, as I was prepping the canard for primer I happen to really note the color of the boat paint on the headrest GPS antenna cover and the ice shields. It’s not a bright white, as the primer is not, so I’ll be calling Jamestown Distributors this week to figure out the way ahead on that. I want the white on my bird to be as white as possible… not the 1970’s dull off-white stuff. So I’ll be evaluating the paint further as I move forward.