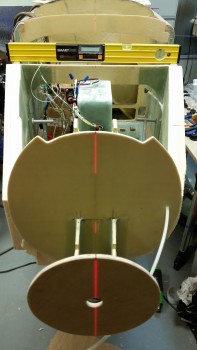

I checked the forward F-7.75 bulkhead mount with the cured BID tapes at the BC1/Napster junctions. The alignment is spot on with the front bulkhead CL matching the other fuselage bulkhead down the line.

My pulling over the F-7.75 nose bulkhead that 1/2″ to the right wasn’t without consequence however. Not surprisingly, it created an offset in my BC1s where they are slanted to the right so that the angle between the right BC1 and Napster is slightly less than 90° while the angle on the left side is slightly greater than 90°. This also effected the actual F-7.75 bulkhead straightness a hair. When I measured the distance between the front bulkhead and Napster at the widest point I got 10.0″ exactly on the right and a hair over 10.1″ on the left.

Here’s a wider angle shot of the front nose bulkhead mounted in place.

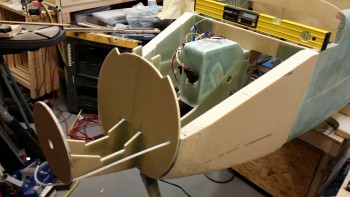

And a shot of the BID tape layups attaching the BC1s to Napster.

On my to-do list was to trim another 0.1″ more of foam & glass off the right side of the gear strut channel (left in the pic). The gear strut wasn’t showing any more rub marks, but it was very close to touching when the gear was up in the channel.

I then started working to construct & mount the brake line fittings mini-bulkheads that will house the union fittings, one on each side. If I were ordering these fittings I would spend more money to get the bulkhead union fitting, but since I have these on hand I’ll go the cheaper & quicker route and use them.

Since the threaded flare nub makes it difficult to get an outline of the perimeter of the union nut portion, I grabbed an equivalent sized standard nut to use as a template.

Here’s another shot showing the equivalent sized nut to the union nut section.

I then drew out the mini-bulkhead plate on yet another piece of Finnish Birch plywood that was used as a jig on the main landing gear.

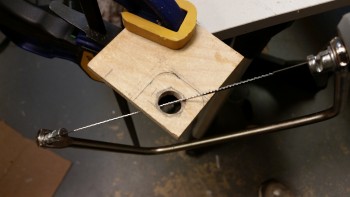

I clamped it down and drilled a small starter hole.

Since I’m not sophisticated enough to own & operate a CNC mill like some people (ha!), I had to resort to my neanderthal, old skool ways of getting a not-round hole into this piece of wood. I used a 1/2″ spade bit to make the initial hole.

I then routed the blade of the coping saw up through the hole and cut the angled edges of the marked hole to enable inserting the middle hexagon shaped area of the union fitting.

Here’s the union fitting inserted it into the hexagon-shaped hole in the mini-bulkhead fitting.

Presenting the poor man’s bulkhead fitting!

Future mods will require glasswork vs simply pulling & replacing the fitting, but for .50 cents a piece in wood, epoxy & glass, I’ll take it!

Is it just me, or do these look like a nice pair of Double D’s?! haha!

. . . Evil Napster apparently thought so! (Sorry, had to be done!)

Since I had moved the fuselage dolly over a bit I rechecked the angle between the longerons to check the batter mount angle.

The battery cradle mount was just a hair off from the longerons.

And after a little judicious sanding of the battery cradle mounting surfaces in the BC1’s . . .

I was able to match the battery angle to that of the longerons:

Speaking of the battery, here’s a couple of shots when I put ‘er place to see how it fits.

I’m really happy with the positioning of the battery. A general guesstimate of the sidewalls in the battery compartment, and it looks like it will have plenty of clearance all the way around.

I then started work on the battery mount, which is nothing more than a 3″ piece of 2024 aluminum tube that gets mounted across the BC1s in holes drilled near center mass of the 5-ply BID reinforcement pads that I laid up on each side of the BC1s specifically for this purpose.

I started with a small pilot hole

And then stepped up with a couple more sizes of bits on my way up to a 1/2″ hole.

And not wanting to use the 1/2″ spade bit for a cleaner, rounder hole, I found this mojamma bit in my bag of tricks . . . Rock on!

Here are the completed, drilled holes for the battery mounting tube.

And here’s a trial fit of the battery mounting tube. While the tube was in I marked it for cutting.

Since there’s a slight angle with the BC1s, I cut the 2024 tube with my mini German hacksaw that I picked up from Praktiker while in Germany. Das ist gut Ja?!

The battery mounting cross tube will get added to my list of things to Alodine.

The battery will get mounted to the cross tube across 2 axes: longitudinal & lateral (pitch & roll … or front & back, left & right… ). The main mounting device will be a 2″ wide military grade webbing strap that has a buckled clasp and then 6″ of velcro for added oomph. I haven’t finalized the decision on my side-to-side securing strap, but it will mount into threaded plug inserts that will go into the ends of the mounting tube, secured with rivets, etcetera, etcetera.

I then cut & shaped the ends of the H100 high density foam and checked the fit for that.

Here’s a side shot of the H100 foam test-fitted between the BC1 plates.

Since I have more configuring to do before epoxy’s involved in the battery compartment, I turned my sights back onto finishing the myriad of nitnoy tasks in the NOW aft nose area (just cool to be able to say that!).

I had pulled out the tube flaring tool last night, watched a couple refresher videos and practiced flaring a few tubes on 1/8″ aluminum. Not bad. I have the simple block flaring tool, and this monstrosity below. I think it was designed & built during the heyday of the Industrial Revolution . . . could use a few more massive bolt rivets in my book. Ha!

Switching from the small 1/8″ block flaring tool (not pictured) to this one, I shredded the first flare I tried. Ah, lesson #1, go gently Grasshopper! It only takes maybe 3 turns on this bad boy to do the trick, and then once I start feeling pressure, just a hair more, then I STOP. Alle ist gut!

One of my first test tube flarings with, “The Beast.” Not bad. Definitely getting more refined with each one.

One reason I practiced flaring a number tubes is because when it came to flaring the brake line tubing ends in the nose the space was very limited. It was tight, but I did have just enough skosh of room to work within that it wasn’t overly painful to complete the task.

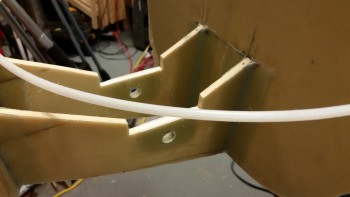

As you can also see in the pic below, I also started working the cross connect brake line tube that will connect the brake line going aft to the main gear wheel brakes to the Matco parking brake valve (PBV) in the nose.

Also note the Adel clamp mid-run on this new brake line cross connect piece, since it will mount to the front wall of NG30 nose area, which is of course Napster (F1-3 bulkhead).

After I flared the brake line tubes on each side, I then covered up some of the pieces parts in the nose to mount the brake line fittings mini-bulkheads. I started by mounting them with 5-min glue, then using a flocro mixture for the fillet I laid up a ply of BID on each side of the mini-bulkheads.

Here’s there right side brake line fitting mini-bulkhead.

For my last construction project of the evening, I constructed 2 nutplate assemblies –using 1/16″ phenolic & K1000-3 nutplates– and mounted them to the lower area of Napster, one on each side, to mount Adel clamps for the new brake line cross connect tubes.

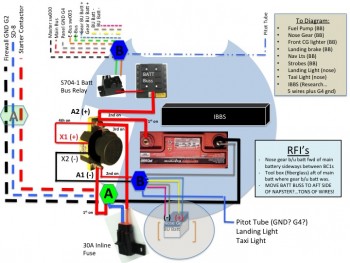

Not shown is an actual good 3-hour chunk of the evening. As I started looking at the battery compartment area to figure out my foam requirements: size, quantity, cutting angles, thickness, etc., I of course was mocking up the components that would reside in that space. As I was figuring out how & where things would go, taking into account wire runs & access, I kept coming back to the fact that I really had no one single account for the shear number of wires flowing in & out of my nose battery compartment. Intuitively, it only seemed like a half dozen or so, but it started turning out to be quite a lot more than that . . . quickly. It was clear to me that I couldn’t really plan out my foam requirements until I had a good account of where my components would go, and I couldn’t account for those devices without a finite accounting of the wire & cable flow.

After physically mocking up the main battery, nose gear back-up battery (which I’m now fairly certain will go forward of the main battery vs aft), battery contactor, battery buss, battery buss relay, and Integrated Backup Battery System (IBBS), I understood that I had to account for literally every wire and cable traversing Napster’s domain to finalize the foam plan for the battery compartment.

Once again, I know my CAD brothers will cringe (and possibly puke a little!) at my Neanderthal PowerPoint notes depicting the battery compartment area. I worked on this and researched my components for a few hours, and it finally got so late I just listed out the remaining items that I need to research/diagram and called it a night.

I did come out of this process with some good finds, which are listed in my RFI (“request for info”) block. The biggie is the realization that with so many wires coming into the battery buss, I’m strongly considering mounting it on the aft side of Napster vs the front side of Napster/inside the battery compartment.

Tomorrow I’ll finalize this research and figure out my battery compartment wiring and component plan, and then will start finalize the planning for the battery compartment foam sides and bottom plates.