I spent a lot of time at my planning table in the house tonight to figure out my nose & nose gear configuration. I was about ready to ask my buddy Marco if he could machine some NG14 spacers (they sit in between the NG30 sides), but then I found them in the EZnoselift kit that Jack Wilhelmson sent me. And here they are:

I then planned out and designed the first & larger of 2 bulkheads that I’ll be building for the Davenport extended nose. I did modify it just a bit, because my front nose hatch will be larger than the stock Davenport hatch, traversing the large bulkhead (thus the indentation at the top). Since I was running low on H250 high density foam, and since it’s extremely expensive (for you non-Canardians, it runs about $105 for a 2 ft x 2 ft sheet … yes, it’s that tough as far as foam goes. And tough to cut too!) I used 2 pieces to make up the larger nose bulkhead (this, incidentally, will mount on the front vertical arms of the NG30 plates).

Of course as soon as I got the foam cut out & the bulkhead pieces together, this part quickly was dubbed with the moniker “Napster”.

Of course as soon as I got the foam cut out & the bulkhead pieces together, this part quickly was dubbed with the moniker “Napster”.

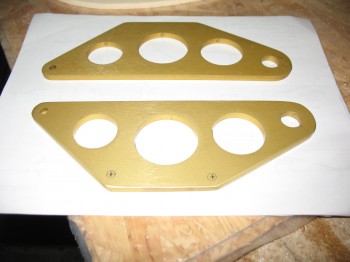

Finally, I measured out the nose lift brackets & correlated them with the NG30 holes. This had to be done before I continued on glassing the NG30 plates, since the next step is to glass in the hardpoints that will secure & be mounted to these nose lift actuator brackets below.