I started out today with a couple quick round of layups. First I 5-minute glued the right strake pilot air vent structure aft wall in place and then glassed it on the front side with a ply of BID. I did use a bit of micro as a fillet. Yes, it looks a bit of a mess with having to go around the upper and lower nutplates, but I think it will hold fine combined with the aft side BID securing it as well.

Here’s a shot of the aft side which I’ll shape and glass tomorrow.

I also laid up a ply of BID on the right wing aileron hinge hard points to protect the aluminum hinges from the carbon fiber, as well as adding a bit more meat for the 82º SS CS screws to bite into. I then peel plied these 3 BID strips.

A while later I pulled the peel ply. In fact, after I snapped this pic I razor cut the top edge of the glass to clean it up.

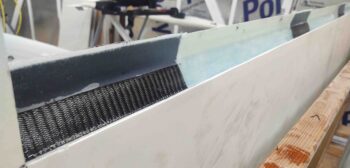

This afternoon I was finally able to get the left wing aileron trough sheer web glassed.

I did lay up the glass pretty much how I did on the right wing, except for this time I went ahead and added the final strip of BID on top of the carbon fiber at each aileron hinge hardpoint.

Here’s the inboard aileron trough sheer web . . .

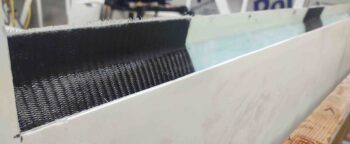

And the outboard sheer web.

A final shot showing that both wings’ aileron trough sheer webs are glassed and complete.

Over the next few days I’ll be working on the right strake pilot air vent structure, the aft nose/avionics cover install, and the wing ailerons themselves. I want to get all these done, plus just a few more items off the list, before I flip the fuselage to glass the bottom external strake skins.