I started today by pulling the peel ply from the Right wing root LWA7 layup & the aileron control tube channel.

I then razor trimmed the LWA7 BID layup.

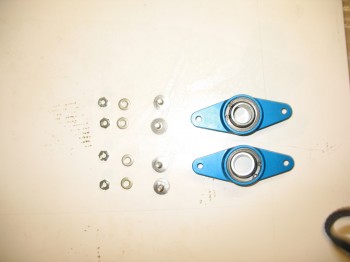

I drilled a 1-1/8″ hole to expose the aileron control tube channel in the Left & Right wing roots. I then used a 1″ sanding drum on a drill & a mini-drum on the Dremel tool to widen the hole diameter to around 1-3/8 inches. . . enough to slide in the aileron control bearings that I picked up from JD Newman at Infinity Aerospace (the same place I got the fighter style stick grips).

I followed the directions JD sent. First, I covered the main bearing assembly with cling wrap, then cleaned off the Clickbonds with Acetone, and finally roughed up the bottom attach surfaces of the Clickbonds with sandpaper in prep for floxing them on.

I followed the directions JD sent. First, I covered the main bearing assembly with cling wrap, then cleaned off the Clickbonds with Acetone, and finally roughed up the bottom attach surfaces of the Clickbonds with sandpaper in prep for floxing them on.

I then mixed a whole wopping 6 g’s total of wet flox slurry & mounted the Clickbond/ Bearing assemblies to Left & Right wing roots. As you can see below I used a large screwdriver through the center hole on each assembly–duct taped in place to each wing–to keep pressure on the aileron bearing assembly, and thus the Clickbonds getting floxed onto the wing root surface. I then let the flox cure.