This blog post actual covers today and yesterday.

Yesterday was all about prep work for the individual strake components. I sanded the foam edges adjacent to the top & bottom flanges on the strake LE structures.

I also broke out the laser level and marked the 17.4 WL on the fuselage and CS spar, as well as on the ribs, baffles, etc. I also did a final trim and cleanup on all the component pieces.

Today I got to work on setting up a wood cross bar and then marked the centerline on the wood using my laser level.

I then marked the BL23 and BL45 locations on each of the CS spar front faces.

I then cleaned up and added another long straight board and measured and marked the CL, BL23 and BL45 on that as well. I then trial fitted the aft part of the BL23 rib and the BL45 rib, using hot glue & clamps to keep them in place. First the left side . . .

With the aft sections of the BL23 ribs in place, I could then determine how much of an extension was required for the BAB, or Baggage Area Baffle, which is the aft internal wall for the fuel tank. Since I cut the GIB strake opening much farther aft –nearer to the CS spar– for GIB comfort, I need to add an extension to the BAB baffle to reach from the midpoint of the BL23/R23 rib to the aft end of the GIB strake opening.

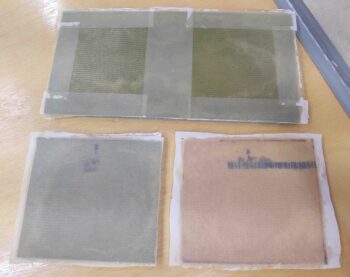

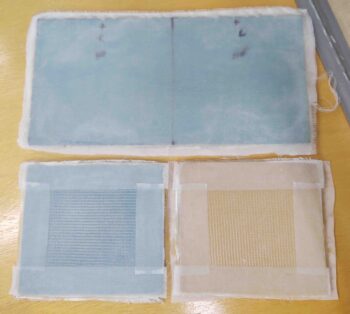

I laid up both side extensions on one piece of 3/8″ foam for now (the top), using EZ-Poxy for the internal layup (shown). In addition, I laid up a ply of BID each on 2 small foam plates that will be added aft fuel walls on the outboard side of the strake between the R45 and OD ribs. With the OD rib the new outboard fuel wall, I’ll place a fuel tank wall about 2/3rds aft from the LE towards the spar to keep the fuel towards the front and minimize negative aft CG effects. It should become clear what these are for within the next few days.

With the layups complete and curing, I then got to work cleaning the PVA off the interior pre-fab strake LE structures. I used a heated concoction of white vinegar and Dawn dish soap and it worked a treat, albeit with a bit of elbow grease scrubbing with an abrasive 3M pad. You can see the strake LE on the left has no more PVA residue, while the one on the right still has an extensive amount on the interior surface.

This is the PVA-laden strake LE above after a few minutes of soaking with the vinegar & Dawn soap solution. I then scrubbed it thoroughly afterwards.

I also sanded the interior glass surfaces of the strake LEs with 100 grit sandpaper.

With the interior glass surfaces cleaned and sanded, I then did an initial test fit of the left strake. As you can see, it definitely needs some trimming… especially noteworthy is how far out the BL23 kink is on the strake LE piece.

A closeup of the left strake LE BL23 kink before trim.

I then spent about an hour slowly trimming down the outboard and inboard edges of the left strake prefab LE.

I eventually got fairly close, but still need a last final trim or two to dial it in. Still, I’m happy to have a visible LE at this point of the strake build… definitely not something I’d have if I was doing the plans method!

Here’s a look at the inside edge of the left strake LE. By simply being taped into place it’s of course off just a bit, but definitely close at this point.

And a shot from the other side of the fuselage.

Since I glassed the strake fuel foam panels earlier in the day, my last task for the evening was to layup a ply of BID on the other side to allow them to cure overnight. Since the opposite sides of all these panels won’t be touching fuel, I went ahead and used MGS epoxy for both ease of layups and a quicker cure time.

I also peel plied these layups as well.

Tomorrow will be a half work day since I have plans for New Years Eve. But I will make every effort to bring in the New Year with both strake leading edges trimmed to fit and ready for mounting!