Today I spent good little bit finishing up taping some content for the next video in the queue, which I should have out tomorrow. I also spent well over an hour editing the new content before getting a bit of work done in the shop.

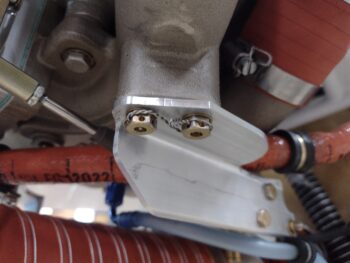

The bolts for the engine plenum-mounted throttle cable bracket have the drilled heads for safety wiring, but like the bolts on the mixture cable bracket, these too are short-threaded with the threads only going up halfway on the bolt shank. I mounted them in the lathe chuck and added a good 3/16″ more threads with a die and then cleaned them up for mounting to secure the throttle cable bracket. I also used blue Loctite and then wired them after I torqued them to around 100 in-lbs.

Not a perfect safety wire job, but it will do for now.

I also wired up the RAM air lever actuator in the hell hole. I tried to use simple crimp-on butt splice connectors, but the actuator wires are too small… even with the wire tripled up it pulled out of the first connector when I did the pull test.

So I carefully soldered spliced the wires together and then covered the splice with heat shrink.

The test from the wires behind the panel to manipulate the RAM can butterfly valve open/closed worked a treat… so one more task complete and in the books!

I have at least a good hour of editing left on my next video that I want to get posted before I move onto working full bore on the engine install.