On my latest trip to North Carolina I was able to stop by Marco’s on the way down, spend some time with him and his Long-EZ at his hangar, and then attend a local EAA meeting.

The next day (today) Marco and I printed out the latest cardboard version (#3) of my instrument panel before I left for my NC hangar.

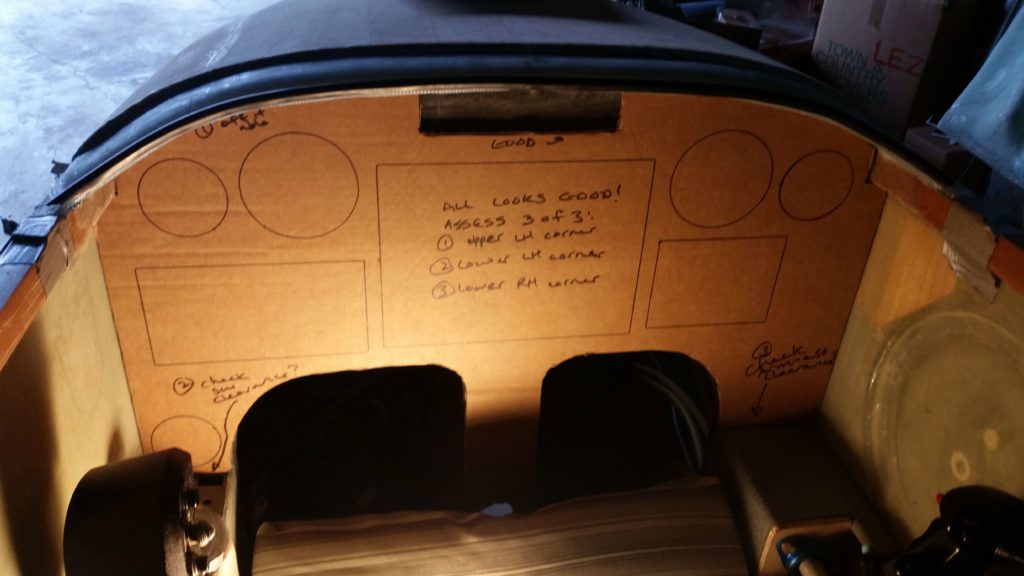

After unloading all the hangar stuff from my load I then quickly cut out the perimeter of the cardboard panel mockup to test fit it in place. Note that I didn’t cut out any of the internal area to ensure the panel was as strong and rigid as possible for the test fit.

The cardboard test panel fit well, but it still needs just a couple minor tweaks: shaving off about 0.020″ on the upper left edge and also shaving about 0.050″ off each vertical edge. I also need to assess clearance between the lower corners on each side of the panel with the respective armrests and switches.

I then quickly popped in the version #2 of the NG-30 cover that covers the open hole between the NG-30 uprights, the aft bulkhead and the Napster bulkhead.

This latest NG-30 “hole” cover fit much better than the last one and best of all, it doesn’t interfere with the nose hatch closing in place.

With two of my primary checks out of the way, I then departed the hangar and unloaded the rest of the stuff into my storage unit.