As I’ve stated before, as a prerequisite to starting the interior portion of the strake build there are a few things I want to get done while I have good access to the back seat area pre-strakes. One of those is to get all the wiring from the front of the plane to the back, and vice versa. I’ve pretty much met that goal, so today I’m simply cleaning it all up.

I started off with finally getting the GRT EFISs’ magnetometer wires ran up to the instrument panel, along the fuselage side wall.

Part of the process of running the magnetometer wires above was to clean up all the wiring in the hell hole. What’s left to do? I have a pair of wires to run up to the D-Deck, and a pair to bring down into the hell hole. Besides that, I have 3 wires to terminate to pretty much be finished with the hell hole wiring. To be clear, there will still be some wires to deal with that transit through the firewall to the engine compartment.

I then cleaned up the 2 separate wire bundle runs in the back seat area. You can see the big power wires, both in size and current capacity, are in the bottom bundle (yellow). The smaller wires are bundled together and a few inches above the lower bundle.

Here’s the back seat area just aft of the pilot’s seat. The wires looped up underneath the side panel will be terminated soon and then added back into the bundle.

I then set the GIB seat kickplate in place. I will have to mod & cut the front top corner a bit for it to fit with the way I’m running the wire bundles, but so far so good.

I then test fitted the GIB right side armrest over the wire bundles. It fit fine and at this point needs no mods. Although I will reserve final judgment regarding required modifications after I mount the final aft control stick tube and ensure clearance for that (another pre-strake task).

Here’s a wider shot of the back seat area with panels in place over the wire bundles. I’m very happy with the results so far.

By the way, those 2 pairs of yellow wires that are lying in the seat pan are the leads to the back seat warmers. I’ll terminate those when I get the seats back from Oregon area and can determine how long I need those leads to be.

Another prerequisite task that needs to be done before I press forward with the interior strake build, leading edge, etc. is mounting the oil heat lines along the GIB seat left side.

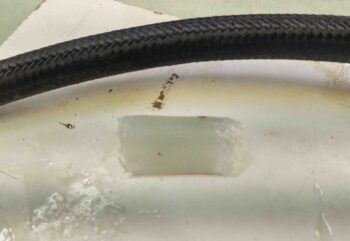

An issue is the thin edge on the left lower pass-through hole in the GIB seat back. I made the beginnings of a protective sleeve for the lower oil line using 3 plies of BID. I then peel plied it and wrapped it with duct tape to keep it curved around the oil line.

A few hours later I took the duct tape off. At some point I got some separation of the glass layers, or a delam . . . not sure what happed.

Here it is trimmed a bit with the peel ply removed.

And another shot of it off the oil line. I’ll sand it down and add another ply tomorrow to account for the thinner area caused by the delam.

Pressing forward!