Today was one of those tedious work days where it seemed like there was a ton of work done without a lot of results to show for it.

I started by pulling the RAM air scoop/hell hole hatch cover from the bottom fuselage. I had to carefully rock it back and forth, up and down to get it to break free from the glassed flange that was gripping the mold-release packing tape on the inside surface of the aft RAM air scoop/hell hole hatch cover.

The flange turned out fine, and here’s another shot of it.

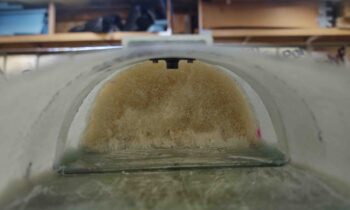

And a somewhat fuzzy shot looking through the aft end of the firewall bridge.

I then pulled peel ply, trimmed and cleaned up this forward flange on the firewall bridge.

I then spent a bit of time aligning and prepping stuff, that finally led to my installing a K1000-3 nutplate as the final aft secure point for the RAM air scoop/hell hole hatch cover.

Here’s an exterior shot of the latest installed screw point to secure the RAM air scoop/hell hole hatch cover. Thankfully this screw point install didn’t mess up the nice flow between the forward RAM air scoop and the shape of the firewall bridge.

I then spent a good half hour pulling peel ply and cleaning up the RAM air scoop structure aft end: the bottom cowling. Here’s a couple shots of the cleaned up pocket that now exists on the front edge of the bottom cowling.

I then set the cowling back in place and added some weights to each side of the new protrusion to press the cowling lip into better alignment with the firewall bridge.

After taping up the bottom lip of the pocket on the front of the bottom cowling –as a mold release– I then laid up a 2-ply lip and 3 more plies in the center for a 5-ply CAMLOC/Skybolt receptacle mounting flange… yes, it’s a bit difficult to tell since the colors blend, but the layup is down in there. I also peel plied the layup.

One last shot of the glassed aft flange (AKA bottom cowl CAMLOC flange) on the firewall bridge.

I then left this layup to cure overnight.