I started out fairly early this morning to get the last set of 2 pairs of CAMLOCs installed on the belly of the fuselage to secure the RAM air scoop. Unlike the aft flange-mounted pair of CAMLOCs, these 2 are much more challenging in that when I cut into the added foam layer of the aft bottom fuselage, the depth wasn’t far enough to allow the CAMLOCs to compress far enough and operate as designed.

Last night, after pondering on it for a bit, I decided to press forward and simply cut further and deeper into the original bottom skin of the fuselage —directly beneath the GIB seat pan— and get my needed 1/8″-3/16″ added depth there.

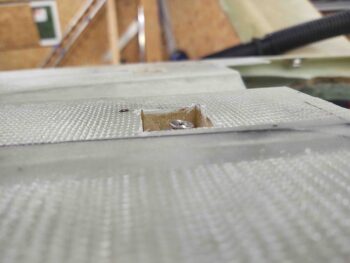

In the pic below you can see I did exactly this on the right side (bottom of pic) . . .

I then tested out a -2 CAMLOC installed in one of the threaded-CAMLOC receptacle phenolic blocks. It fits! . . . whew!

I then did the other side… here I show some of the mess involved in doing so.

I then taped up and floxed the threaded-CAMLOC receptacle phenolic blocks into the bottom of each hole, so that technically the top of each CAMLOC block is floxed directly to the underside of the GIB seat pan glass.

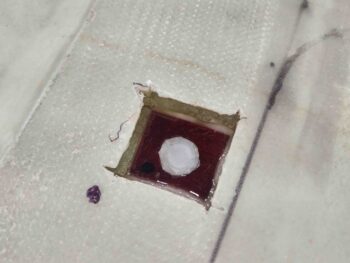

I then laid in 2 plies of BID with a center hole cut out for the CAMLOC. I then inserted, tucked, jammed the glass up under the lip around the edges of each square cutout. I then mixed up drier micro and pressed the glass fully into the recesses along the edges.

Here’s the results. Not bad. Also not pretty. But it will definitely work!

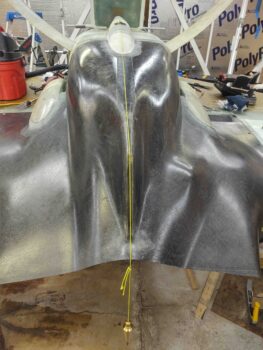

And a wider angle shot so you can get your bearings on where all this is going on.

I then ran a plumb down the aft centerline of the RAM air structure and bottom cowling to ID the spot for the bottom cowling BDC CAMLOC.

I then installed what should be the last CAMLOC I install while the bird is flipped inverted… the next round of CAMLOC installs should come while I’m installing the upper cowling.

I then remounted the bottom cowling and tested out my BDC CAMLOC install… worked a treat!

And again, thankfully nether RAM air scoop/hell hole hatch cover bottom center screw nor bottom cowling bottom center CAMLOC distorted the RAM air scoop aft structure in any way.

I grabbed a shot here showing the latest additions to the RAM air scoop/hell hole hatch cover: the right side CAMLOC and BDC screw.

And a couple shots of the new RAM air scoop flange-mounted CAMLOCs. The depth on these threaded-CAMLOC receptacle phenolic blocks into the fuselage belly was more than adequate since I ended up needing a -8 CAMLOC stud (whoa!)… which I only currently have 1 on hand. I’ll order a couple more next time I submit an order to ACS or Skybolt.

It was getting late in the evening and my last couple of tasks were minor ones, but ones I wanted to cross off my list.

First was laying up a couple plies of BID around the aft opening of the forward RAM air scoop… the side attached to the hell hole hatch cover. This opening got beat up fairly badly when I extracted the aft RAM air scoop piece —with freshly glassed flange— from this section.

As you can see, I then peel plied this layup.

Next, I removed the RAM air can and added some dry micro to the fillet on the inside of the RAM air scoop aft segment, at the junction with the forward firewall face. I”ll note that this will be an iterative process, so this is just another positive step in the right direction. I still need to clean up this application of micro and then probably add at least one more round.

I then let the micro and layup cure overnight.