I started out today by sanding and shaping the micro fillet I inlayed around about half of the junction between the aft RAM air segment and the front face of the firewall. I’ll do one final tweak, but I’d say this gets me very close to where I need to be… at least 80-90%.

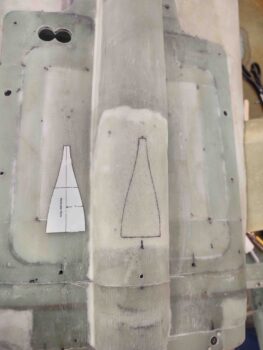

I then got to work on the RAM air scoop aft structure-mounted NACA scoop that will supply cooling air to both the PMAG electronic ignition and the engine driven fuel pump. The template I used was right out of a CSA article on NACA/flush-mounted scoops.

Now, to be clear this is a bit of an experiment on yes, an experimental aircraft. I say this because there are 2 factors that make this a non-typical NACA scoop install… at least in my book. I could very well be wrong of course.

First, the segment of RAM air scoop structure that this NACA is embedded into is not flat, as you can see here.

Next, and although I didn’t get a shot of it (yet). The portion of the RAM air scoop aft structure where this NACA scoop is located is just aft of where the profile of the scoop structure starts to turn upwards to eventually blend into the bottom cowling. Since it’s not on a straight and level segment of the bird I’ll have to monitor how it does.

To be even more clear, if this turns out to be a big fail it would take maybe 2 days to rip it out, fill the pocket with pour foam, glass over with a ply of BID and then spend a day or two painting it. Barely any, if any, added weight in removing it.

I then got busy on the NACA fitting that will jut out of the aft side of the NACA scoop. This fitting will slide into a connector that will connect the NACA to a 1.25″ diameter SCAT tube that carries the air into the engine compartment. I had been shooting for a 1.5″ diameter SCAT tube, but space is tight in this area, especially in the firewall bridge.

Once I got the configuration of the aft NACA fitting set (or so I thought), I secured it with tape and then poured foam around it.

Here’s a bit after I hacked off some of the pour foam. Note the blue foam in the front portion of the NACA fitting to keep pour foam out.

I then test fitted the NACA fitting position and didn’t like what I saw. It was a bit too high and too angled down. It was a good (better?) position most likely for air flow (that’s the whole point, right?!) but getting the RAM air scoop/hell hole hatch cover on and off was just not going to happen with the NACA fitting in this position. I needed to lower it just a hair, and straighten/level it just a hair more (less angled) for it to work.

Here’s the final position I settled on. My intense background in armchair engineering makes me think this will get cooling air to the targets pretty darn close to what the previous position would have…. at least that’s what I choose to believe! <grin>

I micro’d the bottom portion (as situated in the pic) and laid up some BID around it to secure the NACA fitting.

I also taped up the end of a 1.25″ aluminum tube with a taped up toilet paper roll sticking out of the end to make my male/female connector to connect to both the NACA fitting above and into 1.25″ diameter SCAT tubing. I then peel plied this 3-ply BID layup.

My last task for the evening was to use the original somewhat-aerodynamic S-glass grazing nub —in lieu of a hockey puck… this was before Marco machined me a very aerodynamic/cool bumper from a hockey puck— from Feather Light as a mold for my bottom center line-mounted, aft-facing video camera. I didn’t need quite the height for mounting the camera and I definitely didn’t need a heavy, solid S-glass piece to mount it into… but I liked the shape so I just glassed a few plies of scrap BID over it.

I’m guessing in all my machinations tonight I forgot to grab a layup pic of the video camera mount housing, but a few hours later I pulled the layup from the mold and cleaned it up. Here it is.

Tomorrow I’ll continue to work on the NACA scoop and all the tasks on the bottom of the bird so I can get it finished for paint and then flipped back upright post haste.