For a number of years my buddy Marco has helped me out with making stuff in the machining realm, be it metal or plastic . . . on the lathe, mill or 3D printed. I’ve always greatly appreciated his fantastic work and wonderful help, but also had always planned on learning the magic of machining to facilitate not only creating components for my Long-EZ, but for many other projects as well.

Thus then, another recent segue in my build –stemming from my back injury (all good now) and subsequent house selling delay– was to prep for the upcoming onslaught of machining projects in the hopper that will need to be completed before my bird takes flight. Yes, admittedly a good number of these required components are the result of self-inflicted mods and stylistic preferences, but regardless all these parts need to be completed for the plane to be completed as well.

The time finally came, as I knew it would, for me to knuckle and buckle down to get serious about my machining abilities, specifically in regards to learning CAD (Fusion 360) and having CNC-capable machines both on a Mill and Lathe (3D printing will follow shortly). Again, with so many components that need to be machined, I could no longer in good conscience ask Marco to take time out of his busy schedule to do the copious amounts of machining required to create my Long-EZ parts (not that he’d have the time to do them all anyway).

Since I had already done a fair amount of research on the CNC equipment side of the house, I decided to start there. After returning from my holiday sojourns, and with my first scheduled instrument training flight nearly a week away, I decided to nug out the equipment and materials requirements for both my lathe and mill CNC conversions.

Since the mill is higher on the priority list –I do have my lathe on hand– I decided to start with it first. In addition, since my mill will have 3 axes vs. the lathe’s simple 2 axes, it would be easier to par down the mill’s CNC electrical diagrams to convert them over for lathe CNC diagrams.

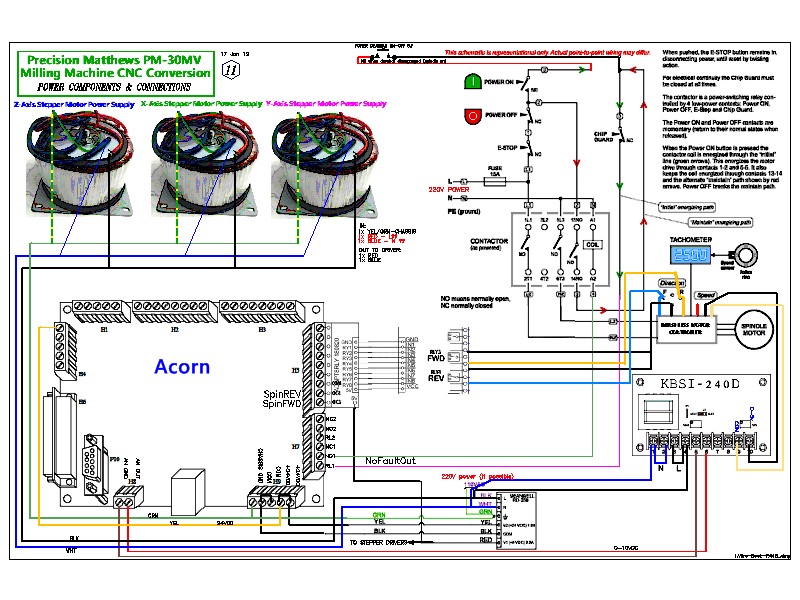

After a good 3 days of intense research, emails, phone calls and reading, my plan came to life at which point I captured over 90% of it all in 4 electrical diagrams. Midway through the process of creating these electrical diagrams, a discussion I had with Marco sparked an epiphany of sorts at which point I decided to upgrade the machining mill I plan to buy from a Precision Matthews PM-25MV to a PM-30MV. In short, the PM-30MV provides more travel in the X, Y and Z axes, and it has a more powerful 2 HP (vs 1 HP) motor that provides more torque and higher RPMs. Lastly, the PM-30MV is much heavier, and is thus a more stable, rigid platform for CNC operations.

So without further ado, here is the first of my wiring diagrams for the CNC conversion of my (planned) Precision Matthews PM-30MV Machining Mill.

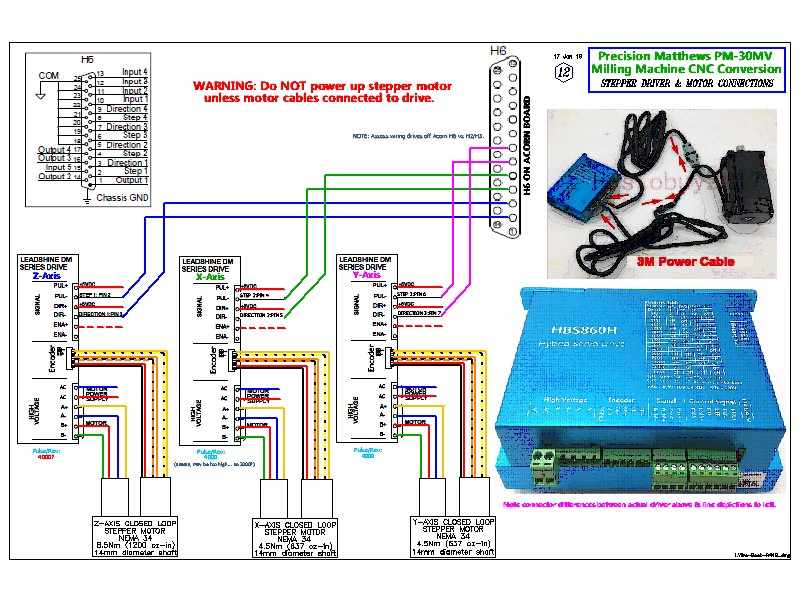

As you may have noted in the diagram above, I made a final decision on the CNC controller hardware and software with the Centroid Acorn system. I also decide to “go ugly early” by ordering the first of my closed-loop stepper motors, which are much more expensive than the open-loop stepper motors (most common) but much more capable for CNC. These closed-loop stepper motors use upgraded (again, in comparison) drives compared to open-loop stepper motors.

This diagram depicts the motor data connections between the Acorn board and drives, and also the data and power connections between each drive and motor.

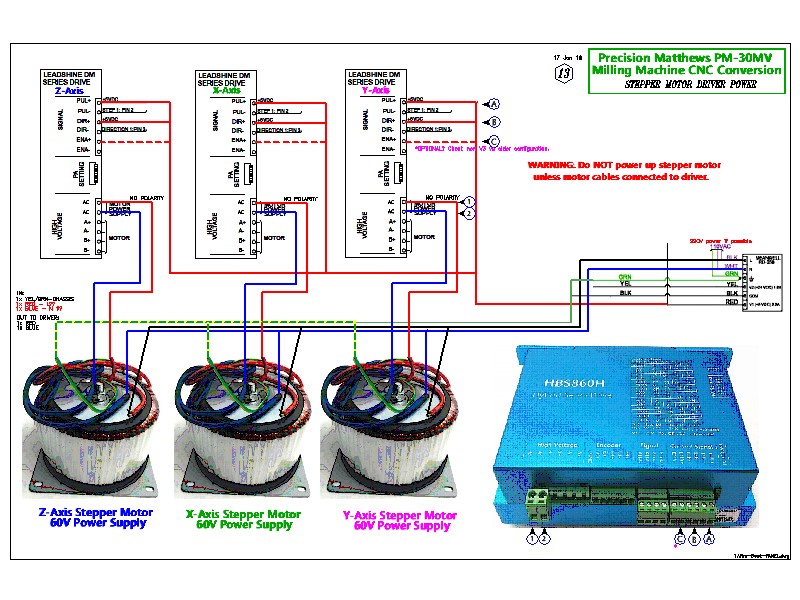

I then figured out the power circuits for the 5V and 60V power between the Acorn power supply, individual axes drives and axes power supplies.

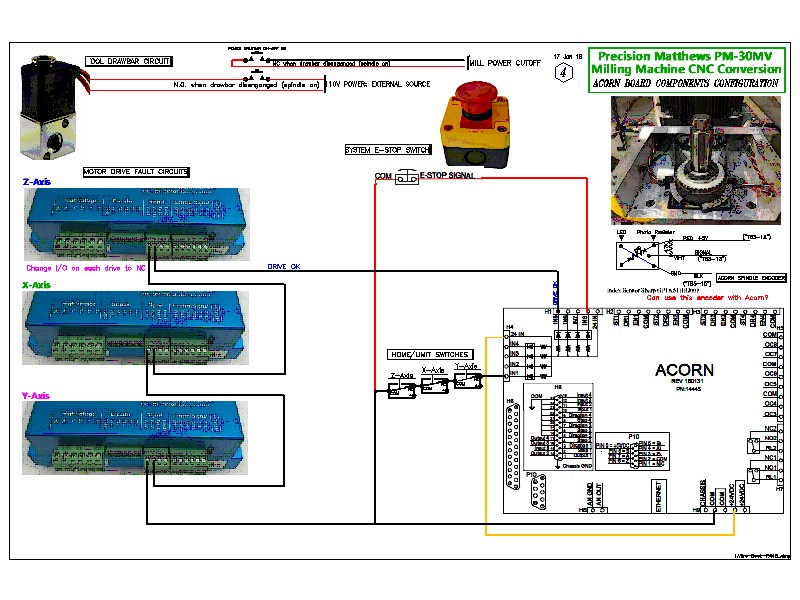

Finally, I made up a diagram to depict the remaining discreet components that make up the CNC system: power drawbar air valve, the E-Stop switch circuit, spindle speed encoder, drives’ alarm circuit, and home/limit switch connections.

Good stuff Bro!

Thanks Brother!