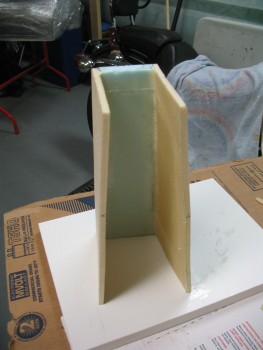

Tonight I razor trimmed pieces, pulled peel ply & cleaned up the peel ply strings from the headrest layup. After the layups cured, I was left with 2 assemblies: the front piece and the two sides/back wall as one unit.

I then dry fitted front to right side wall assembly… doing one side at a time to minimize complexity. I drilled holes for nails and preset those before glassing.

I then dry fitted front to right side wall assembly… doing one side at a time to minimize complexity. I drilled holes for nails and preset those before glassing.

I then mixed up epoxy, micro’d the front wall piece to the right side wall piece, set with nails, cleaned up the exuding micro & then taped up the joint tight.

I used fairly thick micro paste to fillet the corner, and then pre-pregged 1 Ply BID corner tape just a hair under 2″ wide so it would fit under 2″ peel ply tape.

After the corner was laid up I peel plied it with the 2″ wide tape.

I also rough measured, cut & laid up two 1/4″ foam pieces with 1 ply BID for the headrest base and GPS antenna shelf. I threw some peel ply on these last pieces and called it a night.