I started with a list of about 10 things to get done today. Well, I finished 2 of them! Between getting a late start and going out to dinner with friends this evening, I was merely able to get the lower seat back glassed.

I prepped the 1/4″ thick x 1-3/8″ yellow foam addition by adding a couple of extensions covered with duct tape to the outer edge of the yellow foam piece. The reason for these extensions is that when they’re removed after the glass cures there will be about a 1/4″ glass overhang for the connecting foam piece that will be glassed in from the top side seat back assembly. In short, this glass overhang will be the meeting point between the lower seat back assembly and the upper seat back assembly.

I then scurried up a piece of BID for the layup.

And some for the BID tape that I’ll be laying up in the corner to add strength.

I micro’d up the foam and added a fillet in the corner.

I laid up the large ply of BID first, then laid up the corner tape. Once that was all finished I peel plied the lower edge and the corner tape.

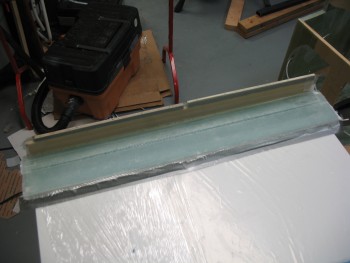

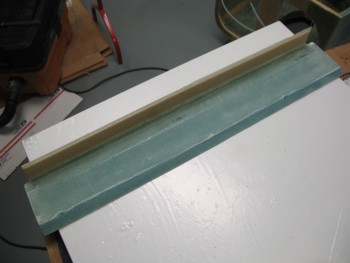

A few hours later I razor cut the piece, pulled the peel ply and cleaned it all up.

Below shows the 1/4″ piece I added to the lower seat back piece, and the glass overhang on the aft side of the yellow foam.

Of course I mocked up the newly glassed piece along with the other seat back components. Below you can finally see the notch for the roll bar’s rectangular cross bar.

I added the cross bar so I could see how it all looks together.

Here’s a shot from from just a tad bit forward so you all can see the front edge of the cross bar aligned with the front edge of the lower seat back. Looks like the fit should be pretty darn good.

And here’s the final mock-up shot of evening.