Yes, my dear friends, I’m calling the canard complete!

I started off today by cutting out the right elevator weight notch in the canard.

Here I’m checking the opacity of the glass beneath . . . ha!

I measured everything out using the right elevator as a template and then got to work on micro’ing the sides and laying up 1-ply of BID to protect the foam.

BTW, here’s the left side still in the same state I left it in after last night’s cheese grating.

And here are the smaller bits ‘n pieces after I hit them with some 80 grit.

After I got the weight notch sorted out, I mixed up some West epoxy and started applying epoxy swipes to the remaining parts of the bottom of the canard that weren’t finished (swoosh tips, swoosh tip inboard rib, weight notches, etc.).

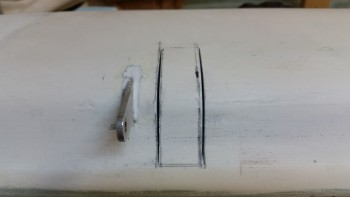

Here’s a shot of the right inboard swoosh tip area after a couple of coats of epoxy. And a shot of the glassed right elevator notch with 1-ply BID.

Below is a shot about 9 hours after the one above, and the tips are covered with 5 coats of epoxy. I’lll let it cure overnight and sand it tomorrow.

On with the nose gear!

I measured everything out with the sidewall brackets that sit internal to the NG30 plates and hold up the electric gear actuator.

Unfortunately my zeal got the best of me. After checking something in the gear actuator install instructions I ran across a statement where the holes in the brackets (not shown) need to be 3/8″ away from the side of the bracket at the center of each hole. Mine were set at a 1/4″ away from edge to hole’s center. This changed the angle required to get the holes drilled correctly for the brackets. Not a huge a deal, I’ll just have to widen that top hole a bit aft.

Oh, and speaking of NG30’s and stuff, look what just came in the mail: my nose! Says on the box that some assembly is required! Haha!

Interestingly, I was just having a conversation the other day with a good builder buddy of mine talking about how some builders have yellow foam in their build that isn’t polyurethane, but actually Divinycell (H45). Well, guess what? My “blue” Divinycell foam showed up yellow. I mean, I asked ACS if they could send me the lightest Divinycell possible . . . but I was talking WEIGHT, not COLOR! ha!