I started off today by trimming the glass around the aft nose sub-structure large avionics access hole. I then gave it a good sanding and ensured the top and bottom edges were NOT sharp! Note the micro in edges of the CAMLOC and hinge tab slots.

I then did a fair amount of sanding and even a little Dremel work on the interior surfaces of the elevator fairings and the interfacing fuselage sidewall to get the fairings to seat properly and all the hardpoints (re)aligned after disturbing everything with these screw- tab-securing internal plies of BID.

I also drilled the counter sinks in each of the holes for the CS screw heads to sit flush into. Here’s a shot of the screws installed and secured by the inside nutplate assemblies.

I grabbed these shots to show the flush fit of the screws. Although I did hit the left screw hole (right pic) again with the counter sink bit to remove just a hair more material.

I then removed the outboard wing bolts and swapped them out with the much longer bolts I inexplicably bought years ago. These bolts are definitely long enough to mount a 2×4 on.

I wanted to take advantage of the fuselage being in a straight nose-up position during the flip to add some pour foam to the face of F28. The face of F28 has some differences in elevation and is not even nor symmetrical, so I just want to clean that up a bit. Obviously much easier if the typically vertical-situated F28 is in the flat/horizontal position, and with pour foam it will literally take just a few minutes to add it. I created a dam around the perimeter of F28 with duct taped cardboard to allow for this quick aside during the fuselage flip.

I went to Harbor Freight (after hunting awhile to get some gas!) and picked up a remote control 2500 lb. winch. I then spent a good 45 minutes cutting 2×6 reinforcement plates to allow me to mount the winch about as high up as possible on the front of the shop.

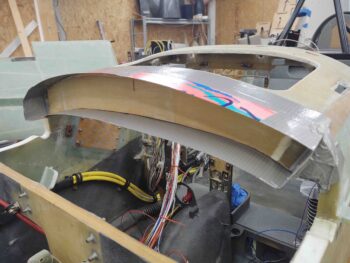

I then spent another good hour+ finishing up the right half moon structure.

I then did the musical chairs dance of moving all my tools, equipment and wings on dolly around to allow for extricating the fuselage from the shop.

I then spent almost another hour mounting the half moons to the wing mounting hard points on the CS spar.

Of course these pics of the plane ready for flip remind me of the TIE fighters in the movie Star Wars!

It was fairly late, so I threw a tarp over the fuselage and called it a night.

Tomorrow will be the big fuselage flip day!