I will apologize right up front for not getting the requisite pictures that I promised of the elevators in their progressive state. I will attempt to tell the story better visually as it progresses. Right now I have the offending Right elevator with one Micro Skim coat applied to the underside of it and I will be sanding it down & applying either another Micro Skim coat or a pure epoxy wipe tomorrow.

In the mean time, to ensure I have everything I need to hot-wire another elevator, I traced the Roncz elevator templates off the plans onto a piece of paper.

Which resulted in this:

I had been to Home Depot earlier getting various items for the build, including a 2×4 to lengthen my hot-wire cutter. While there, I found these Formica samples in the cabinet aisle, so I snagged them. Not bad for free!

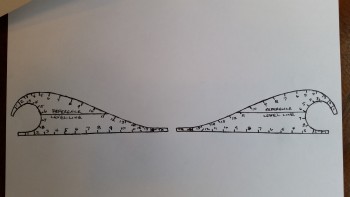

I then spray glued the elevator templates, after rough cutting them, to the Formica samples.

OK, I’m going to get on a huge soap box here! I have learned a ton from many who have gone before and completed these airplanes, but in general, there are many builders who are like birds in a nest squawking the same old tired songs. I read in the plans (the culprit) and then in a million and one places that Formica is the best for hot-wiring templates. Now, I admit I could have done something wrong in my application of employing Formica in creating my elevator templates, but the bottom line IMO is that Formica sucks!!!! It broke, shredded, snapped, crumbled, etc. as soon as my jig saw touched it. So, after getting ready to go back to the store to buy some stuff that ACTUALLY works!! I found an old license plate that would work. So, instead of using the worthless piece of crap Formica,I moved on to metal:

Ok, again, no pics here. But in the end it didn’t matter what I used. After messing around & testing my hot-wire saw, it’s just plain old & tired. I test drove it using the metal elevator templates I made, but it just didn’t have enough oomph to cleanly cut the foam. I thought I would at least try. So, instead of spending more money on getting new parts for the hot-wire saw, and more time, I’m punting and will simply order another elevator core (technically a pair) from Steve at Eureka CNC.

Finally, just thought I’d throw in a pic showing that I finished & trimmed the canard ice shields: